The environmental impact of PVC in Wellington boots is significant. This is because Polyvinyl Chloride (PVC) is a plastic derived from oil that is non-biodegradable and generally not recycled. The production process harms air and water quality, and its disposal can release toxic chemicals, creating environmental pollution at every stage of its life.

The fundamental issue with PVC Wellington boots lies in their linear "cradle-to-grave" lifecycle. From its resource-intensive creation to its permanent status as waste, PVC poses environmental risks at every stage.

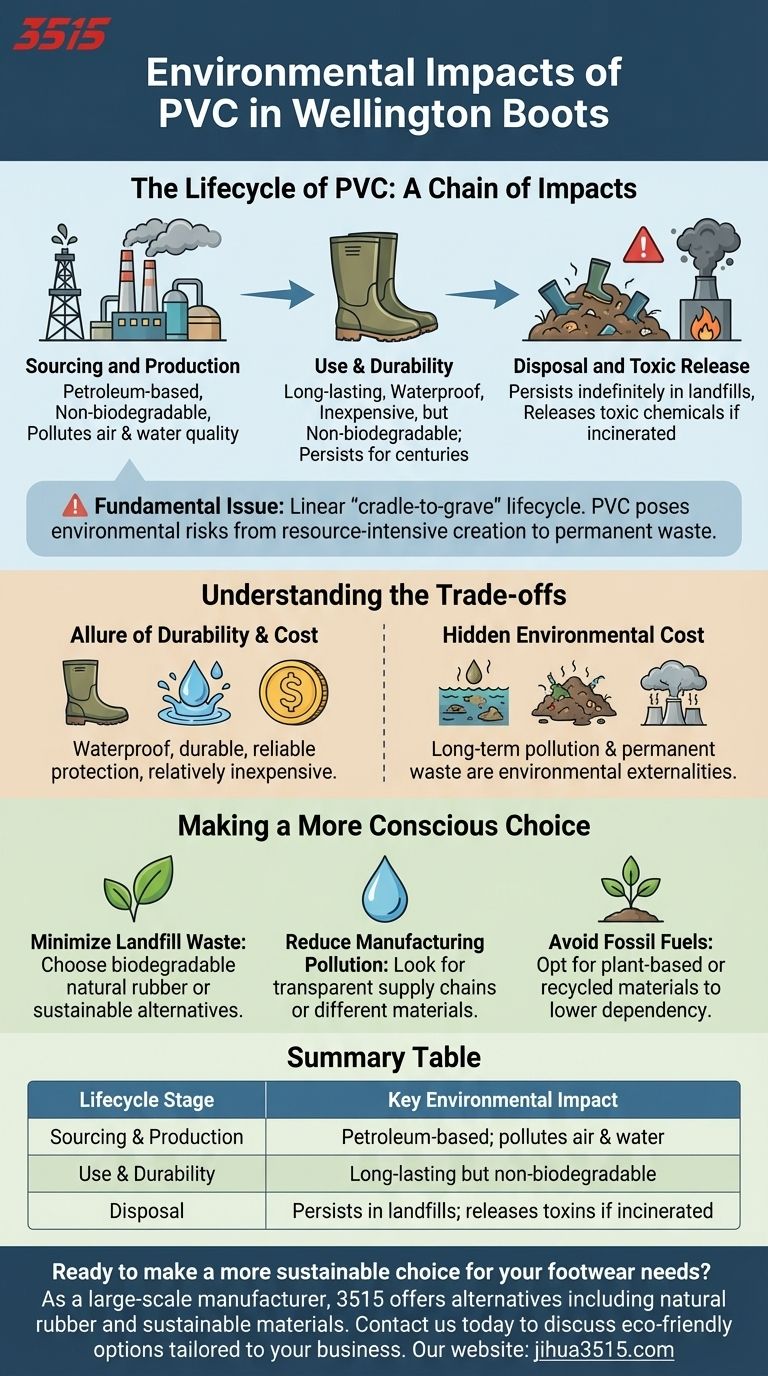

The Lifecycle of PVC: A Chain of Impacts

To fully grasp the environmental cost, it's essential to look at the material's entire journey, from factory to landfill.

Sourcing and Production

PVC is a petroleum-based plastic, meaning its creation starts with the extraction of fossil fuels.

The manufacturing process itself is known to be a source of pollution, negatively impacting both air and water quality in the surrounding areas.

The Problem of Persistence

The defining characteristic of PVC is its durability, which becomes a major environmental flaw at the end of its life.

Because it is non-biodegradable, a discarded PVC Wellington boot will not decompose. It will persist in a landfill or the natural environment for centuries, contributing to long-term plastic pollution.

Disposal and Toxic Release

Disposing of PVC is problematic. When landfilled, it simply takes up space indefinitely.

If incinerated in an attempt to manage waste, PVC can release toxic chemicals, which poses a risk to air quality and public health.

Understanding the Trade-offs

While the environmental drawbacks are clear, it's important to understand why PVC became the standard material for Wellington boots.

The Allure of Durability and Cost

PVC is an effective material for its intended purpose. It is waterproof, durable, and relatively inexpensive to produce.

These qualities make it possible to manufacture affordable and functional boots that offer reliable protection from water and other liquids.

The Hidden Environmental Cost

The low purchase price of PVC boots does not reflect their true environmental cost.

The long-term impacts of pollution from manufacturing and the permanent waste created at the end of the product's life are externalities borne by the environment, not the consumer.

Making a More Conscious Choice

Your decision-making can be guided by prioritizing which environmental impact you are most concerned about.

- If your primary focus is minimizing landfill waste: Acknowledge that PVC is non-biodegradable and will persist for centuries, and look for boots made from natural, biodegradable rubber or other sustainable alternatives.

- If your primary focus is reducing pollution from manufacturing: Be aware that PVC production harms air and water quality and consider brands that are transparent about their supply chain or use different materials.

- If your primary focus is avoiding fossil fuels: Remember that PVC is derived from oil, so choosing boots from plant-based or recycled sources can lower your dependency on non-renewable resources.

Ultimately, understanding the material in your products is the first step toward making a choice that aligns with your environmental values.

Summary Table:

| Lifecycle Stage | Key Environmental Impact |

|---|---|

| Sourcing & Production | Petroleum-based; pollutes air and water |

| Use & Durability | Long-lasting but non-biodegradable |

| Disposal | Persists in landfills; releases toxins if incinerated |

Ready to make a more sustainable choice for your footwear needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and functional footwear for distributors, brand owners, and bulk clients. We offer alternatives to PVC, including natural rubber and other sustainable materials, helping you reduce environmental impact without compromising on quality or performance.

Contact us today to discuss eco-friendly Wellington boot options tailored to your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- What material are PVC boots made from? A Guide to Their Pros, Cons & Best Uses

- Why are wellies a good choice for gardening? Find Your Perfect Fit for Muddy Tasks

- Why is grip important in wellington boots? Ensuring Safety and Stability on Slippery Surfaces

- What are the common parts of a wellington boot and their functions? A Guide to Boot Anatomy & Performance

- What is the conclusion for maintaining rubber boots? A Simple 3-Step Guide for Long-Lasting Wear

- What makes PVC boots easy to wear? Discover the Simple, Slip-On Design for Ultimate Convenience

- Why are rubber boots beneficial in hazardous environments? Unmatched Protection & Easy Decontamination

- What are Wellington boots and why are they popular? Unmatched Protection for Wet & Muddy Conditions