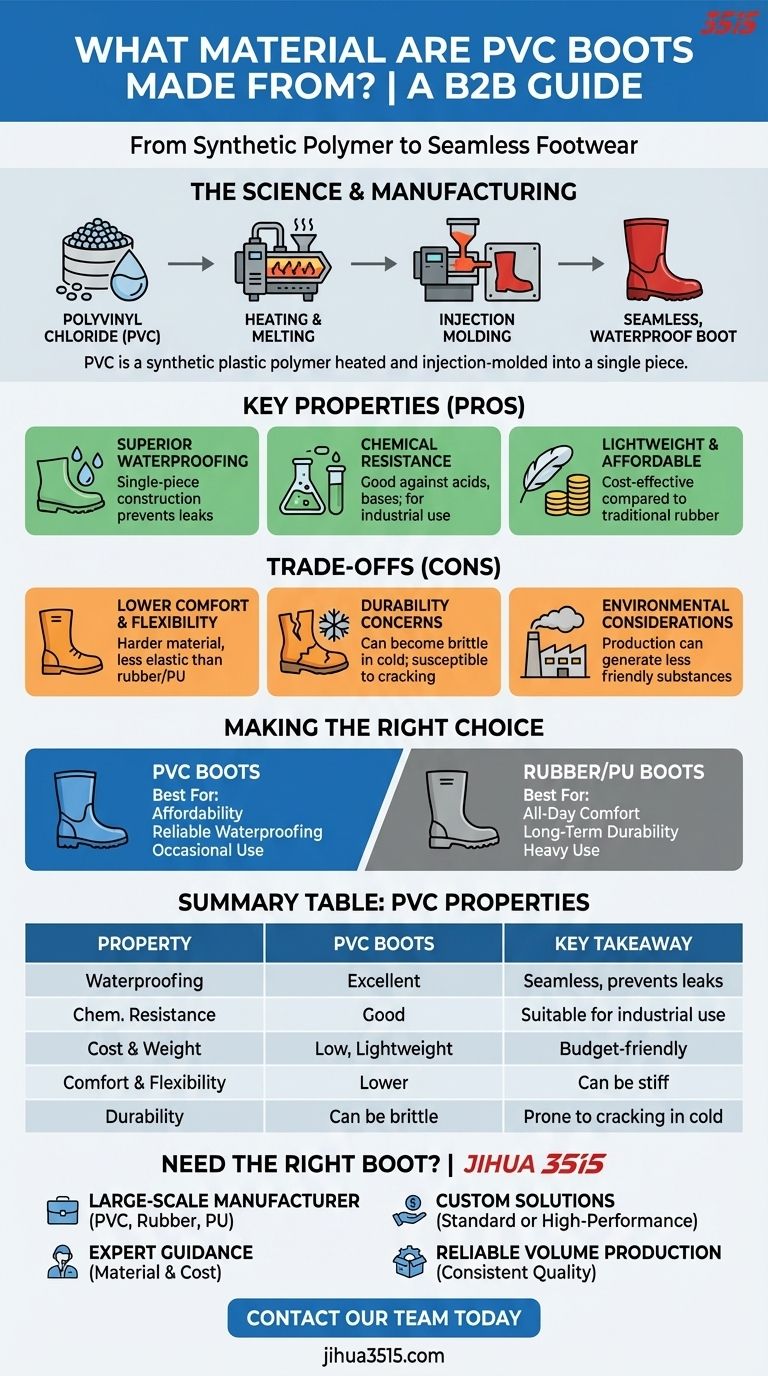

At its core, a PVC boot is constructed from Polyvinyl Chloride, a widely produced synthetic plastic polymer. This material is heated and formed into a solid, waterproof boot using a process called injection molding, creating a seamless and highly protective piece of footwear.

The essential takeaway is that PVC is chosen for its exceptional waterproofing and low cost. However, these benefits come with significant trade-offs in comfort, flexibility, and long-term durability when compared to materials like rubber or polyurethane.

The Science of PVC: From Raw Material to Boot

To understand why PVC boots perform the way they do, we must first look at the material itself and how it's manufactured.

What is Polyvinyl Chloride (PVC)?

Polyvinyl Chloride is the world's third-most widely produced synthetic plastic. In its rigid form, it's used for pipes and construction materials.

To create boots, manufacturers use a flexible version of PVC. This gives the final product properties that can mimic natural rubber while being much less expensive to produce.

The Injection Molding Process

PVC boots are created through injection molding. The PVC material is heated until molten and then injected into a boot-shaped mold.

As the material cools, it solidifies into the final shape of the boot. This single-piece construction method is key to its waterproof nature, as it eliminates seams that could leak.

Key Properties of PVC Footwear

The material and manufacturing process give PVC boots a distinct set of characteristics that make them suitable for specific applications.

Superior Waterproofing

Because they are formed in a single, seamless piece, PVC boots are inherently waterproof. This makes them highly effective for keeping feet dry in wet environments.

Chemical Resistance

PVC is known for its good resistance to a variety of chemicals, acids, and bases. This property makes it a common choice for footwear in agricultural, industrial, and cleaning-related jobs.

Lightweight and Affordable

Compared to traditional rubber boots, PVC is generally lighter and significantly less expensive to manufacture. This cost-effectiveness is one of its primary advantages.

Understanding the Trade-offs

While PVC offers clear benefits, it's crucial to understand its limitations. No material is perfect, and PVC's advantages come with compromises.

Comfort and Flexibility

PVC tends to be a harder and less elastic material than rubber or polyurethane (PU). This can lead to lower comfort, especially during long periods of wear, as the boot doesn't flex as naturally with the foot.

Durability Concerns

While strong, PVC can become brittle in cold temperatures and may deteriorate more quickly than high-quality rubber. It can be more susceptible to cracking or splitting with heavy use over time.

Environmental Considerations

The production process for PVC can generate substances that are less environmentally friendly compared to the processes for natural rubber.

Making the Right Choice for Your Needs

Selecting the correct boot material depends entirely on your specific requirements for cost, comfort, and performance.

- If your primary focus is affordability and reliable waterproofing: PVC is an excellent, budget-friendly choice for occasional or light-duty use.

- If your primary focus is all-day comfort and long-term durability: You should consider investing in alternatives made from higher-quality rubber or polyurethane (PU).

- If your primary focus is protection from specific chemicals: PVC is a strong contender, offering reliable resistance at a very accessible price point.

Ultimately, understanding the properties of PVC allows you to choose the right tool for the job.

Summary Table:

| Property | PVC Boots | Key Takeaway |

|---|---|---|

| Waterproofing | Excellent | Seamless, injection-molded construction prevents leaks. |

| Chemical Resistance | Good | Suitable for agricultural and industrial environments. |

| Cost & Weight | Low cost, lightweight | A budget-friendly option for light-duty use. |

| Comfort & Flexibility | Lower than rubber/PU | Can be stiff and less comfortable for extended wear. |

| Durability | Can become brittle | May crack in cold weather or with heavy use over time. |

Need the Right Boot for Your Specific Application?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including PVC, rubber, and polyurethane (PU) models.

We can help you source the perfect footwear by providing:

- Expert Guidance: Leverage our material expertise to choose the best boot for durability, comfort, and cost.

- Custom Solutions: Whether you need standard PVC boots or high-performance alternatives, we can meet your specifications.

- Reliable Volume Production: Benefit from our manufacturing scale to ensure consistent quality and on-time delivery for your orders.

Let's discuss your requirements and find the optimal solution for your market. Contact our team today for a consultation!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management