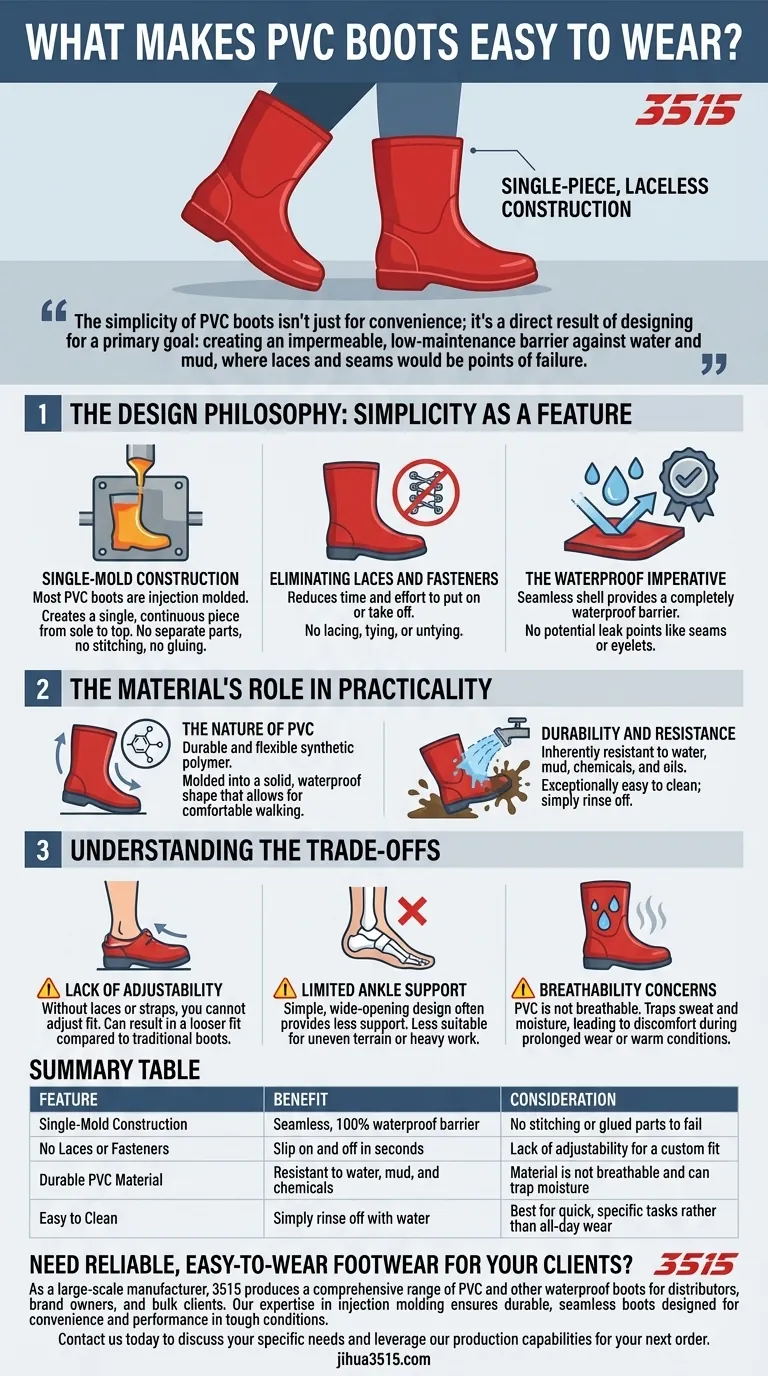

At its core, what makes PVC boots easy to wear is their single-piece, laceless construction. Most are made from a single mold of polyvinyl chloride, creating a seamless boot that you simply step into without needing to tie, buckle, or fasten anything.

The simplicity of PVC boots isn't just for convenience; it's a direct result of designing for a primary goal: creating an impermeable, low-maintenance barrier against water and mud, where laces and seams would be points of failure.

The Design Philosophy: Simplicity as a Feature

The ease of use you experience with PVC boots is a deliberate design choice driven by the need for absolute reliability in wet and dirty environments.

The Single-Mold Construction

Most PVC boots are manufactured using an injection molding process. This creates a single, continuous piece of material from the sole to the top of the boot, eliminating the need for separate parts that require stitching or gluing.

Eliminating Laces and Fasteners

The most obvious reason for their ease of wear is the absence of laces. This removes the entire process of lacing up, tying, and untying, reducing the time and effort required to put on or take off the footwear.

The Waterproof Imperative

This minimalist design serves a critical function: waterproofing. Seams, eyelets, and stitching are all potential points for water to seep in. By creating a seamless shell, the boot provides a completely waterproof barrier, which is its main purpose.

The Material's Role in Practicality

The choice of Polyvinyl Chloride (PVC) is central to the boot's functional design and ease of use.

The Nature of PVC

PVC is a durable and flexible synthetic polymer. It can be molded into a solid, waterproof shape that still allows for enough flex to walk comfortably, making it an ideal material for this type of slip-on footwear.

Durability and Resistance

This material is inherently resistant to water, mud, chemicals, and oils. This means the simple, easy-to-wear design is also exceptionally easy to clean—you can simply rinse them off.

Understanding the Trade-offs

While the slip-on design is a major advantage, it comes with inherent limitations you should be aware of.

Lack of Adjustability

The primary trade-off for convenience is fit. Without laces or straps, you cannot adjust the boot's tightness around your foot or ankle. This can result in a looser fit compared to traditional laced boots.

Limited Ankle Support

The simple, wide-opening design required for easy entry often provides less ankle support than a structured, laced boot. This makes them less suitable for hiking on uneven terrain or for work that requires significant ankle stability.

Breathability Concerns

PVC is not a breathable material. While it excels at keeping water out, it also traps sweat and moisture in. This can lead to discomfort during prolonged wear or in warmer conditions.

Making the Right Choice for Your Goal

Understanding these design principles helps you decide if a PVC boot is the right tool for your specific needs.

- If your primary focus is quick use in wet or muddy conditions: The slip-on convenience and absolute waterproofness of PVC boots are unmatched.

- If your primary focus is a secure fit and ankle support for heavy work: A traditional laced work boot will likely provide the necessary stability and adjustability that a PVC boot lacks.

- If your primary focus is all-day comfort in varied conditions: You may want to consider boots made from more breathable materials, as PVC can trap moisture.

Ultimately, choosing the right boot means matching its core design strengths to the task at hand.

Summary Table:

| Feature | Benefit | Consideration |

|---|---|---|

| Single-Mold Construction | Seamless, 100% waterproof barrier | No stitching or glued parts to fail |

| No Laces or Fasteners | Slip on and off in seconds | Lack of adjustability for a custom fit |

| Durable PVC Material | Resistant to water, mud, and chemicals | Material is not breathable and can trap moisture |

| Easy to Clean | Simply rinse off with water | Best for quick, specific tasks rather than all-day wear |

Need reliable, easy-to-wear footwear for your clients?

As a large-scale manufacturer, 3515 produces a comprehensive range of PVC and other waterproof boots for distributors, brand owners, and bulk clients. Our expertise in injection molding ensures durable, seamless boots designed for convenience and performance in tough conditions.

Contact us today to discuss your specific needs and leverage our production capabilities for your next order.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites