While highly protective, the primary drawbacks of steel toe boots are their significant weight, their tendency to conduct hot and cold temperatures, and their potential for discomfort due to a rigid structure. They can also pose an electrical hazard if not properly insulated for that specific risk.

The core issue with steel toe boots is the trade-off between their exceptional impact protection and the practical realities of all-day comfort. The very material that makes them strong also makes them heavy, temperature-sensitive, and unforgiving in fit.

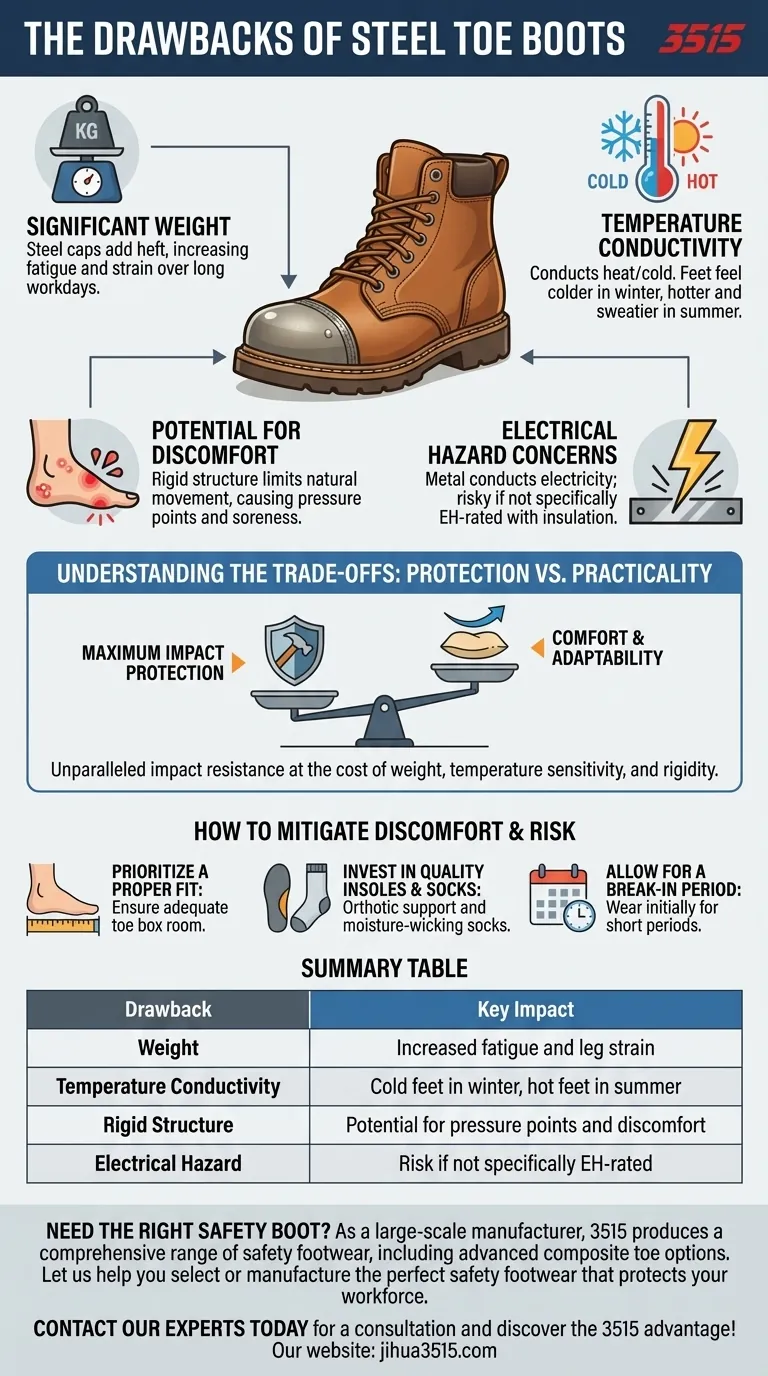

The Core Drawbacks Explained

While steel toe boots are a classic choice for heavy-duty safety, their design comes with inherent disadvantages that can impact daily wear and performance. Understanding these is key to selecting the right footwear for your environment.

The Weight Factor

The most noticeable drawback is their weight. The steel cap adds significant heft compared to non-safety or composite toe boots.

This added weight can lead to increased fatigue over a long workday, putting extra strain on your feet, ankles, and legs.

Temperature Conductivity

Steel is an excellent conductor of energy. This means in cold environments, the steel cap can draw heat away from your feet, making them feel colder.

Conversely, in hot conditions, the steel can absorb ambient heat, contributing to discomfort and sweat inside the boot.

Potential for Discomfort

The rigid nature of the steel cap limits the natural flex and movement of your foot, which can cause discomfort.

If the boot's fit is not perfect, the unyielding steel can create pressure points on your toes and foot, leading to soreness or blisters.

Electrical Hazard Concerns

Because metal conducts electricity, standard steel toe boots can be a hazard in environments with a high risk of electrical exposure.

While many steel toe boots are EH-rated (Electrical Hazard) with insulation to mitigate this risk, it is a critical specification to check if your job requires it.

Understanding the Trade-offs: Protection vs. Practicality

The choice of steel toe boots hinges on a fundamental compromise. You are selecting them for their primary benefit: unparalleled protection against impact and compression injuries.

The Classic Protector

Steel offers the highest level of impact resistance, making it the standard for environments with heavy machinery, falling objects, or significant crushing risks.

This technology is proven and cost-effective, which is why it remains a popular choice despite being relatively outdated compared to newer composite materials.

The Cost of That Protection

The drawbacks—weight, temperature conductivity, and rigidity—are the direct price paid for that level of protection. Newer technologies, like composite toes, were developed specifically to address these comfort and environmental shortcomings.

Therefore, the decision isn't just about safety, but about how much comfort and environmental adaptability you are willing to sacrifice for maximum impact resistance.

How to Mitigate Discomfort and Risk

If the protection of steel is non-negotiable for your job, you can take several steps to minimize the associated drawbacks and improve your daily comfort.

Prioritize a Proper Fit

This is the most critical factor. A boot that is too tight will cause constant pressure from the steel cap, while a boot that is too loose will allow your foot to slide and hit the cap. Ensure there is adequate room in the toe box.

Invest in Quality Insoles and Socks

Factory insoles often provide minimal arch support. Upgrading to a high-quality orthotic insole can dramatically improve support and cushioning.

Likewise, cushioned, moisture-wicking socks can reduce friction and help manage temperature and sweat inside the boot.

Allow for a Break-in Period

Never wear a new pair of steel toe boots for a full workday right away. Wear them for short periods initially to allow the leather and other materials to conform to your foot's shape, which can prevent blisters and soreness.

Making the Right Choice for Your Needs

Selecting the correct safety footwear requires matching the boot's characteristics to your specific work environment and physical needs.

- If your primary focus is maximum impact protection: A steel toe boot is an excellent and often most cost-effective choice, especially for work around heavy machinery or materials.

- If your primary focus is all-day comfort and reduced fatigue: You may want to consider lighter composite toe alternatives, provided they meet your job's safety standards.

- If your primary focus is working in extreme temperatures or around electrical hazards: A composite toe is often superior, but a properly insulated, EH-rated steel toe boot can also be a viable option.

Ultimately, understanding the inherent compromises of steel toe boots empowers you to choose footwear that not only protects you but also supports your well-being on the job.

Summary Table:

| Drawback | Key Impact |

|---|---|

| Weight | Increased fatigue and leg strain |

| Temperature Conductivity | Cold feet in winter, hot feet in summer |

| Rigid Structure | Potential for pressure points and discomfort |

| Electrical Hazard | Risk if not specifically EH-rated |

Need the right safety boot for your team's specific environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We understand the critical balance between protection and comfort. Our production capabilities encompass all types of safety shoes and boots, including advanced composite toe options that offer protection while mitigating the common drawbacks of steel.

Let us help you select or manufacture the perfect safety footwear that protects your workforce without compromising their comfort and productivity.

Contact our experts today for a consultation and discover the 3515 advantage!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- What types of safety toe boots are available for different job requirements? Choose the Right Protection for Your Work

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries