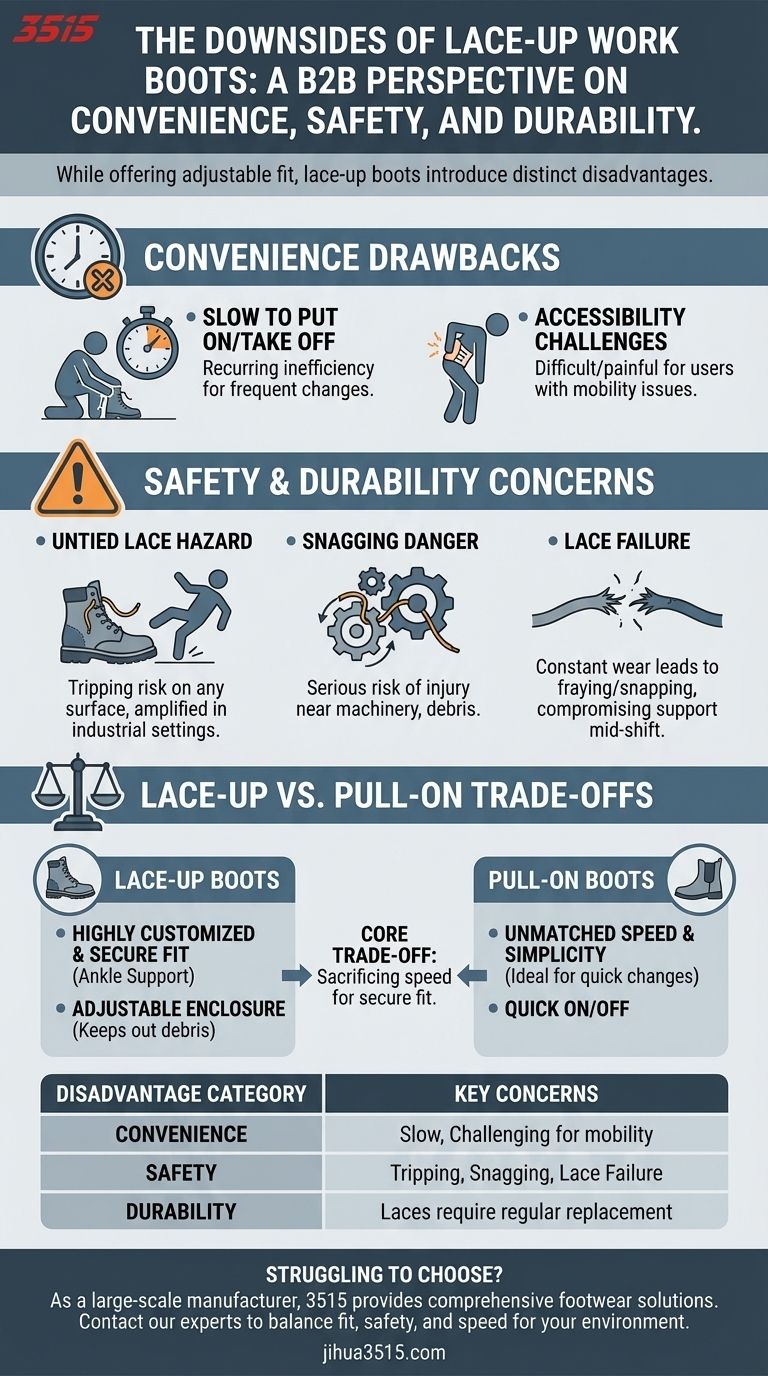

While lace-up work boots are prized for their adjustable fit, they introduce distinct disadvantages in convenience, safety, and durability that must be considered. Their primary drawbacks are the time required for lacing, the potential for laces to become dangerous snag or trip hazards, and the inherent wear-and-tear on the laces themselves.

The core trade-off with lace-up boots is sacrificing speed and convenience for a more secure, customized fit. Understanding this balance is crucial to selecting the right footwear for your specific work environment and daily routine.

The Primary Drawback: Convenience

The most immediate and consistent downside of lace-up boots is the time and effort they demand. This isn't just a minor annoyance; it can have practical consequences in many professional settings.

Slow to Put On and Take Off

Lacing and unlacing boots takes significantly more time than simply sliding into a pull-on style. For workers who are in a rush or need to change footwear frequently throughout the day, this process becomes a recurring inefficiency.

Accessibility Challenges

For individuals with mobility issues or back problems, the act of bending over to tightly lace a pair of boots can be difficult or painful. This makes lace-up designs less accessible for a segment of the workforce.

Critical Safety and Durability Concerns

Beyond convenience, the laces themselves introduce unique points of failure and specific safety risks that are absent in other boot designs.

The Hazard of Untied Laces

An untied lace is a well-known tripping hazard on any surface. In an industrial or construction environment, this risk is amplified by the presence of stairs, scaffolding, and uneven ground.

The Danger of Snagging

More critically, laces can become caught on equipment, debris, or, most dangerously, rotating machinery. This snag hazard poses a serious risk of injury in certain mechanical, agricultural, and industrial jobs.

Risk of Lace Failure

Boot laces are a component that experiences constant friction and tension. Over time, they will inevitably fray and can snap. A broken lace mid-shift renders the boot loose and unstable, compromising support and safety until it can be replaced.

Understanding the Trade-offs: Lace-up vs. Pull-on

The downsides of lace-up boots are best understood when compared to their most common alternative: pull-on boots. The choice between them is a fundamental compromise between security and speed.

Fit and Ankle Support

This is the key advantage of lace-ups. They allow for a highly customized and secure fit around the ankle and instep. Pull-on boots, by contrast, can feel looser and are more prone to "heel slip," which can reduce stability when climbing or navigating uneven terrain.

Speed and Simplicity

Pull-on boots are unmatched for speed. You can put them on or take them off in seconds, making them ideal for environments where you frequently move from outdoors to indoors or for emergency responders who need to gear up instantly.

A Secure Enclosure

The adjustable nature of a lace-up boot allows you to create a tight seal at the top. This can be more effective at keeping out dirt, pebbles, and other small debris compared to the wider, open shaft of a typical pull-on boot.

Making the Right Choice for Your Goal

To select the appropriate boot, you must weigh these disadvantages against the specific demands of your work.

- If your primary focus is speed and frequent on/off changes: The time-consuming nature of laces makes a pull-on style the more practical and efficient choice.

- If your primary focus is maximum ankle support for climbing or uneven terrain: The downsides of laces are a necessary trade-off for the superior stability and custom fit they provide.

- If your primary focus is safety around rotating machinery: The significant snag hazard from laces must be a top consideration, potentially making a pull-on boot a safer option.

Ultimately, the best work boot is the one that directly addresses the unique risks and routines of your daily tasks.

Summary Table:

| Disadvantage Category | Key Concerns |

|---|---|

| Convenience | Slow to put on/take off; challenging for users with mobility issues |

| Safety | Tripping hazard; risk of snagging on machinery; lace failure mid-shift |

| Durability | Laces are a wear-and-tear component that require regular replacement |

Struggling to choose the right work boot for your team's safety and efficiency?

As a large-scale manufacturer, 3515 produces a comprehensive range of both lace-up and pull-on work boots for distributors, brand owners, and bulk clients. Our expertise ensures you get the perfect footwear solution that balances fit, safety, and speed for your specific work environment.

Contact our experts today to discuss your requirements and discover how we can enhance your workforce's safety and productivity.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- What are the advantages of leather work boots? Unmatched Durability & Custom Fit

- What are roper boots, and who are they suitable for? Find Your Perfect Work & Casual Footwear

- What are the main benefits of composite toe work boots? Lighter, Safer, and More Comfortable

- Are work boots suitable for everyday use? The Ultimate Guide to Comfort & Durability

- How can moc toe boots be styled for an Urban Streetwear Edge? Master the Modern Rugged Look

- How do manufacturers ensure a secure fit in light work boots? Discover the Engineering Behind Perfect Fit

- What historical events influenced the development of work boots and western boots? The Industrial Revolution & Frontier Expansion

- Are cowboy boots ok for work? A Guide to Professional Style and Workplace Safety