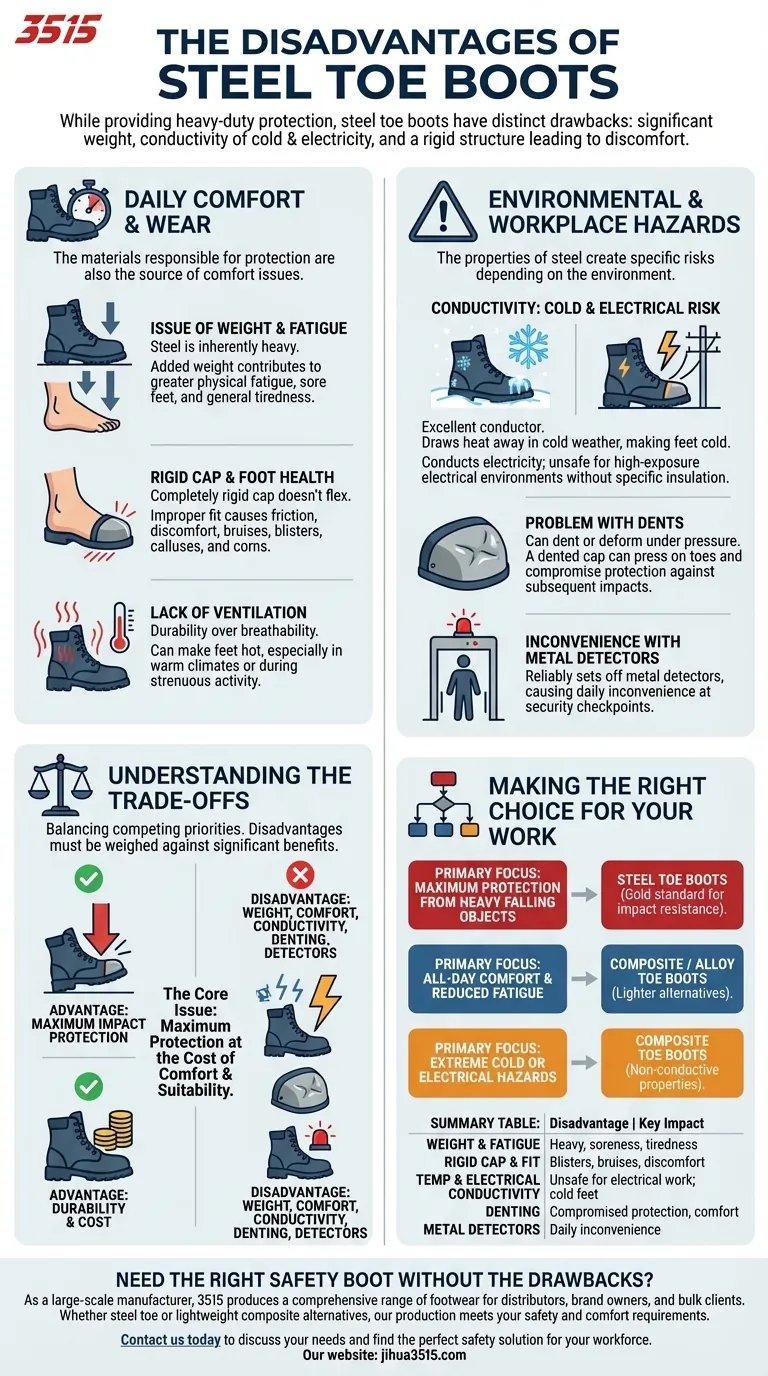

While providing heavy-duty protection, steel toe boots have several distinct disadvantages. Their primary drawbacks are significant weight, which can cause fatigue, their tendency to conduct both cold and electricity, and a rigid structure that can lead to discomfort if the fit is not precise.

The core issue with steel toe boots is the trade-off: you gain maximum impact protection at the cost of weight, comfort, and suitability for certain work environments, such as those with extreme temperatures or electrical hazards.

The Impact on Daily Comfort and Wear

The most common complaints about steel toe boots relate to how they feel during a long workday. The materials and construction responsible for their protection are also the source of their primary comfort issues.

The Issue of Weight and Fatigue

Steel is inherently heavy compared to alternatives like composite materials or aluminum alloys.

This added weight on your feet contributes to greater physical fatigue over the course of a day, potentially leading to sore feet, ankles, and general tiredness.

The Rigid Cap and Foot Health

The steel toe cap is completely rigid and does not flex with your foot. An improper fit can cause the cap to rub against your toes or the top of your foot.

This friction and pressure can lead to discomfort, bruises, blisters, calluses, and corns, especially with prolonged and continuous wear.

Lack of Ventilation

Many heavy-duty steel toe boot designs prioritize durability over breathability. This lack of ventilation can make them hot to wear, particularly in warmer climates or during strenuous activity.

Environmental and Workplace Hazards

Beyond comfort, the properties of steel create specific disadvantages and hazards depending on the work environment.

Conductivity: The Cold and Electrical Risk

Steel is an excellent conductor of temperature. In cold weather, the steel cap can draw heat away from your feet, making them feel significantly colder.

More critically, steel conducts electricity. Standard steel toe boots are unsuitable for electricians or anyone working in high-exposure electrical environments unless they have specific electrical hazard (EH) insulation.

The Problem with Dents

While steel offers immense protection from a single, heavy impact, it can dent or deform under pressure. A dented cap can press on the toes and may not offer the same level of protection against subsequent impacts.

Inconvenience with Metal Detectors

A minor but consistent issue is that steel toe boots will reliably set off metal detectors. This can be a daily inconvenience for workers who must pass through security checkpoints.

Understanding the Trade-offs

Choosing a safety boot is about balancing competing priorities. The disadvantages of steel must be weighed against its significant, time-tested benefits.

Advantage: Maximum Impact Protection

The primary reason steel toes exist is their superior ability to protect against crushing and impact injuries from heavy machinery or falling objects. For many high-risk jobs, this level of protection is non-negotiable.

Advantage: Durability and Cost

Steel toe boots are known for their durability and longevity. The technology is well-established, often making them a more cost-effective option compared to newer composite or alloy toe boots.

Making the Right Choice for Your Work

Selecting the appropriate footwear requires a clear understanding of your job's specific demands and your personal comfort needs.

- If your primary focus is maximum protection from heavy falling objects: Steel toe boots remain the gold standard for impact resistance, and their drawbacks may be an acceptable trade-off.

- If your primary focus is all-day comfort and reduced fatigue: Consider lighter alternatives like composite or alloy toe boots, which offer similar protection with less weight.

- If your primary focus is working in extreme cold or around electrical hazards: A composite toe boot is a much safer and more comfortable choice due to its non-conductive properties.

Ultimately, the best safety boot is the one that provides the necessary protection for your specific role without creating unnecessary discomfort or risk.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Weight & Fatigue | Heavy, can cause soreness and tiredness over long shifts. |

| Rigid Cap & Fit | Can cause blisters, bruises, and discomfort if not perfectly fitted. |

| Temperature & Electrical Conductivity | Unsafe for electrical work; makes feet cold in winter. |

| Denting | A dented cap can compromise protection and comfort. |

| Metal Detectors | Will set off security checkpoints, causing daily inconvenience. |

Need the right safety boot without the drawbacks?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether you need the classic protection of steel toe boots or the lightweight, non-conductive benefits of composite alternatives, our production capabilities encompass all types of shoes and boots to meet your specific safety and comfort requirements.

Contact us today to discuss your needs and find the perfect safety solution for your workforce.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection