The primary disadvantages of rubber work boots are their lack of breathability, significant weight, and often lower durability compared to other materials. These boots create a completely waterproof seal, but that same feature traps heat and moisture, leading to discomfort during prolonged wear.

Rubber work boots are a highly specialized tool, not an all-purpose solution. They sacrifice breathability and long-wear comfort in exchange for absolute protection against water, mud, and certain chemicals.

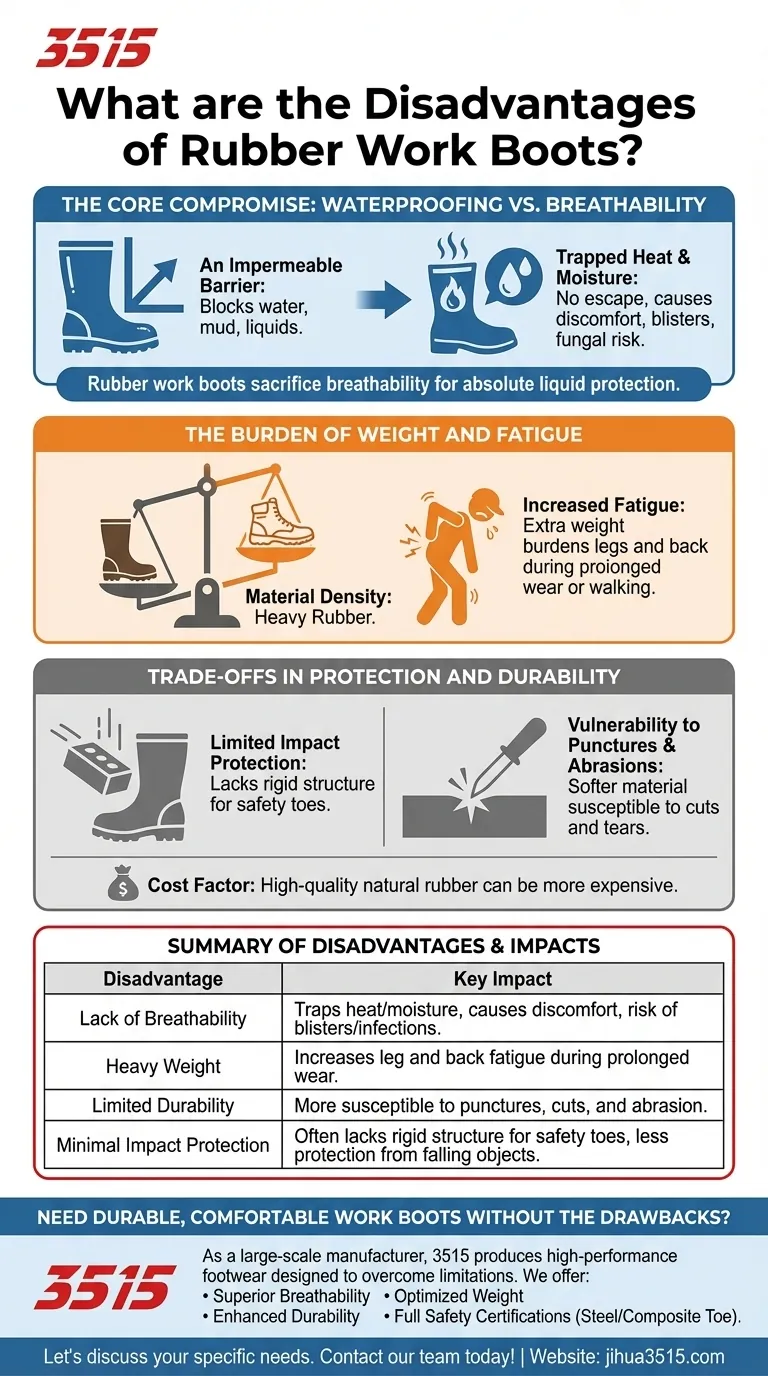

The Core Compromise: Waterproofing vs. Breathability

The most significant trade-off with rubber boots stems directly from the material's core strength: its impermeability.

An Impermeable Barrier

Rubber is non-porous. This quality is what makes it completely waterproof, effectively blocking water, mud, and other liquids from reaching your feet.

The Inevitable Result: Trapped Heat and Moisture

This same non-porous barrier also prevents moisture from escaping. Your feet naturally sweat, and in a rubber boot, that sweat has nowhere to go. This leads to a buildup of heat and moisture, creating a stuffy, uncomfortable environment.

Over a long day, this can lead to discomfort, blisters, and an increased risk of fungal infections.

The Burden of Weight and Fatigue

The physical properties of rubber introduce another set of challenges for the wearer, primarily related to weight.

Material Density

Rubber is a dense, heavy material. Compared to leather or modern synthetic fabrics, a pair of rubber work boots is significantly heavier.

The Impact on the Body

This extra weight can feel burdensome and lead to increased fatigue in your legs and back over a full workday, especially if your job involves a lot of walking or climbing.

Understanding the Trade-offs in Protection and Durability

While offering excellent liquid protection, rubber boots often fall short in other critical safety and longevity metrics.

Limited Impact Protection

Standard rubber boots offer very little protection against impacts from falling objects or compression. Unlike leather or composite boots, the material itself does not provide a rigid structure to shield the foot.

Vulnerability to Punctures and Abrasions

While thick, rubber is softer than treated leather and can be more susceptible to cuts, punctures, and general abrasion. Sharp objects on a worksite can compromise the boot's waterproof integrity more easily.

The Cost Factor

High-quality natural rubber boots can also be more expensive than alternatives like PVC. The process of harvesting latex and manufacturing the boots is often more labor-intensive.

Making the Right Choice for Your Environment

Choosing the correct boot requires a clear understanding of your primary daily tasks and hazards.

- If your primary focus is working in standing water, mud, or with specific chemicals: The absolute waterproof and chemical-resistant nature of rubber boots makes them the correct, specialized tool for the job.

- If your primary focus is all-day wear with varied movement: The lack of breathability and heavy weight make materials like leather or modern synthetics a far more comfortable choice.

- If your primary focus is protection from impact or punctures: You must prioritize boots with certified safety features like steel or composite toes, which are less common in basic rubber boot models.

Ultimately, selecting the right work boot is about matching the tool to the specific demands of your work environment.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Lack of Breathability | Traps heat and moisture, causing discomfort and increasing risk of blisters/fungal infections. |

| Heavy Weight | Leads to increased leg and back fatigue during prolonged wear or extensive walking. |

| Limited Durability | More susceptible to punctures, cuts, and abrasion compared to materials like treated leather. |

| Minimal Impact Protection | Often lacks the rigid structure needed for safety toes, offering less protection from falling objects. |

Need Durable, Comfortable Work Boots Without the Drawbacks?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots designed to overcome the common limitations of standard rubber boots.

We can provide you with boots that offer:

- Superior breathability for all-day comfort.

- Optimized weight to reduce fatigue.

- Enhanced durability with advanced materials.

- Full safety certifications (steel/composite toe, puncture resistance).

Let's discuss your specific needs and how we can deliver the right footwear solution for your market.

Contact our team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- Which industries commonly use safety boots and why? Protect Your Workforce from Top Hazards

- What features are essential in cowboy boots for construction work? Prioritize Certified Safety & Durability

- What is the crucial practice for maximizing the durability of cowboy boots? Rotate Your Boots to Extend Their Lifespan

- What are the temperature ratings and recommended uses for 800g insulated boots? A Guide for Cold-Weather Footwear

- What makes Goodyear Welt boots suitable for harsh environments? Unmatched Durability & Repairability

- What is the difference between engineer boots and work boots? A Guide to Style vs. Safety

- How should one choose the right engineer boots? A Guide to Fit, Material, and Purpose

- What are PVC work boots and how are they made? Your Guide to Durable, Waterproof Footwear