The primary benefit of alloy-toe boots is that they provide robust impact and compression protection, comparable to traditional steel toes, but at a significantly lower weight. By using lightweight metals like aluminum and titanium, these boots reduce foot fatigue over a long workday without compromising on essential safety standards.

The core advantage of alloy-toe boots is the balance they strike. They deliver the high-level protection required in hazardous environments while significantly lightening the load on the wearer, directly translating to increased comfort and reduced fatigue.

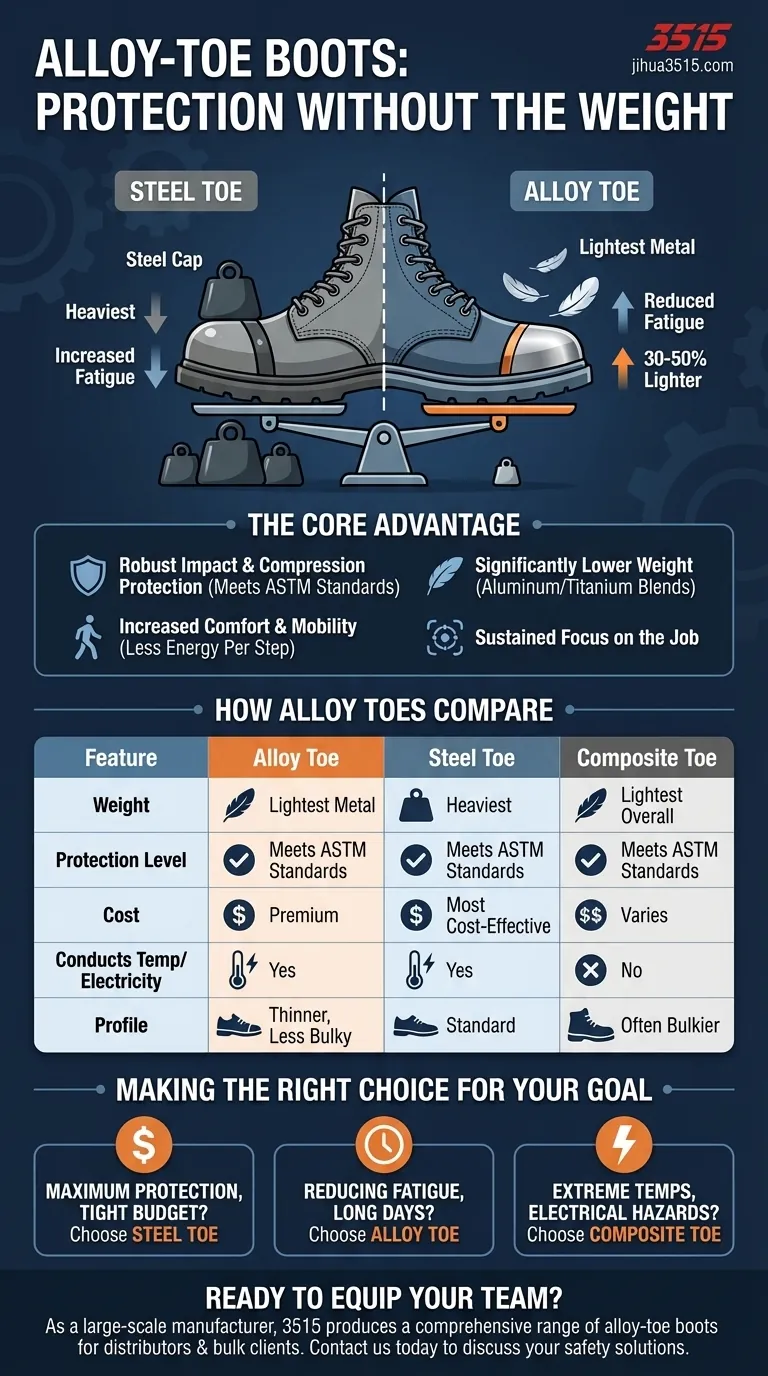

The Core Advantage: Protection Without the Weight

Modern safety footwear is a crucial piece of personal protective equipment (PPE). The evolution from heavy steel to lighter alloys represents a significant step forward in combining safety with wearer comfort.

How Alloy Toes Work

Alloy safety toes are crafted from lightweight metals such as aluminum, titanium, or other metallic blends. These materials are engineered to meet the same stringent ASTM International safety standards for impact and compression resistance as traditional steel toes.

The key difference is density. Metals like aluminum and titanium are much less dense than steel, allowing for a protective cap that is 30% to 50% lighter on average.

The Direct Impact on Fatigue

Reducing the weight at the end of your legs has a compounding effect throughout the day. Less weight per step means less energy expended.

For workers in construction, manufacturing, or warehousing who may walk several miles during a shift, this weight reduction can be the difference between ending the day with sore legs and feeling less physically drained. This allows for greater mobility and sustained focus on the job.

How Alloy Toes Compare to Other Safety Options

Choosing the right safety toe is about understanding the specific demands of your environment. Alloy toes occupy a distinct middle ground between the classic strength of steel and the modern benefits of non-metallic composites.

Alloy vs. Steel Toes

Steel is the traditional standard for safety toes. It is incredibly strong, durable, and the most cost-effective option. Its primary drawback is its significant weight.

Alloy matches the protective standards of steel but offers the clear benefit of being much lighter. This makes it a premium upgrade for roles where both safety and mobility are critical.

Alloy vs. Composite Toes

Composite toes are made from non-metallic materials like carbon fiber, Kevlar, or plastic. They are even lighter than alloy toes and do not conduct heat, cold, or electricity, making them ideal for certain specialized environments.

However, to achieve the same level of protection as metal, composite caps must often be thicker and more bulbous. Alloy toes can often be made with a thinner profile, resulting in a less bulky boot that more closely resembles a standard, non-safety shoe.

Understanding the Trade-offs

No single material is perfect for every situation. While alloy-toe boots offer excellent benefits, it's important to understand their specific context to make an informed decision.

Cost Considerations

Advanced materials come at a price. Alloy-toe boots are typically more expensive than their steel-toe counterparts. The higher cost reflects the more expensive raw materials (titanium, aluminum) and the manufacturing process.

Environmental Factors

Because they are metal, alloy toes will conduct heat and cold, though generally less so than steel. They will also set off metal detectors, a key consideration for workers in secure facilities where composite toes might be required.

Focus on the Whole Boot

The toe cap is just one component. The overall durability, comfort, and protection of a boot also depend heavily on the other materials used. A boot with a full-grain leather upper will offer superior durability and water resistance, while one with synthetic panels may offer better breathability, similar to a tactical boot.

Making the Right Choice for Your Goal

Selecting the correct safety boot requires matching the boot's features to your daily tasks and environment.

- If your primary focus is maximum protection on a tight budget: A traditional steel-toe boot remains the most cost-effective and reliable choice.

- If your primary focus is reducing fatigue during long, active workdays: An alloy-toe boot provides the ideal balance of high-level protection and lightweight comfort.

- If your primary focus is working in extreme temperatures or around electrical hazards: A non-metallic composite-toe boot is the superior and necessary option.

Ultimately, choosing the right footwear is an investment in your safety and daily well-being on the job.

Summary Table:

| Feature | Alloy Toe | Steel Toe | Composite Toe |

|---|---|---|---|

| Weight | Lightest Metal | Heaviest | Lightest Overall |

| Protection Level | Meets ASTM Standards | Meets ASTM Standards | Meets ASTM Standards |

| Cost | Premium | Most Cost-Effective | Varies |

| Conducts Temp/Electricity | Yes | Yes | No |

| Profile | Thinner, Less Bulky | Standard | Often Bulkier |

Ready to equip your team with high-performance alloy-toe boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We specialize in crafting durable alloy-toe boots that combine essential protection with lightweight comfort, helping to reduce worker fatigue and boost productivity.

Contact us today to discuss your specific needs and discover how our manufacturing capabilities can deliver the perfect safety solution for your business.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How does lacing technique affect steel toe boot comfort? Unlock a Perfect, Pain-Free Fit

- What are the primary concerns when choosing between steel-toe and soft-toe boots? Match Your Boot to Your Job's Hazards

- What protection do steel toe boots provide? Essential Safety for Hazardous Work

- How do composite toe boots compare to steel toe boots? A Guide to Maximum Safety & Comfort

- What is the point of steel toe shoes? Essential Protection for Hazardous Work Environments

- How do safety boots provide toe protection? A Guide to Steel vs. Composite Caps

- What are the characteristics of steel safety toes? A Guide to Maximum Impact Protection

- What are the 5 main protections offered by steel toe boots? A Guide to Workplace Foot Safety