Proper lacing is a critical, yet often overlooked, component of steel toe boot comfort. By strategically adjusting your lacing technique, you can distribute pressure evenly across the top of your foot, eliminate painful hot spots, and secure your heel to prevent rubbing and blisters. It transforms the boot from a simple protective shell into a system that works with your foot's unique shape.

The way you lace your boots is your first line of defense against discomfort. While overall comfort depends on fit, socks, and insoles, mastering your lacing technique is the quickest and most effective adjustment you can make to improve your daily experience.

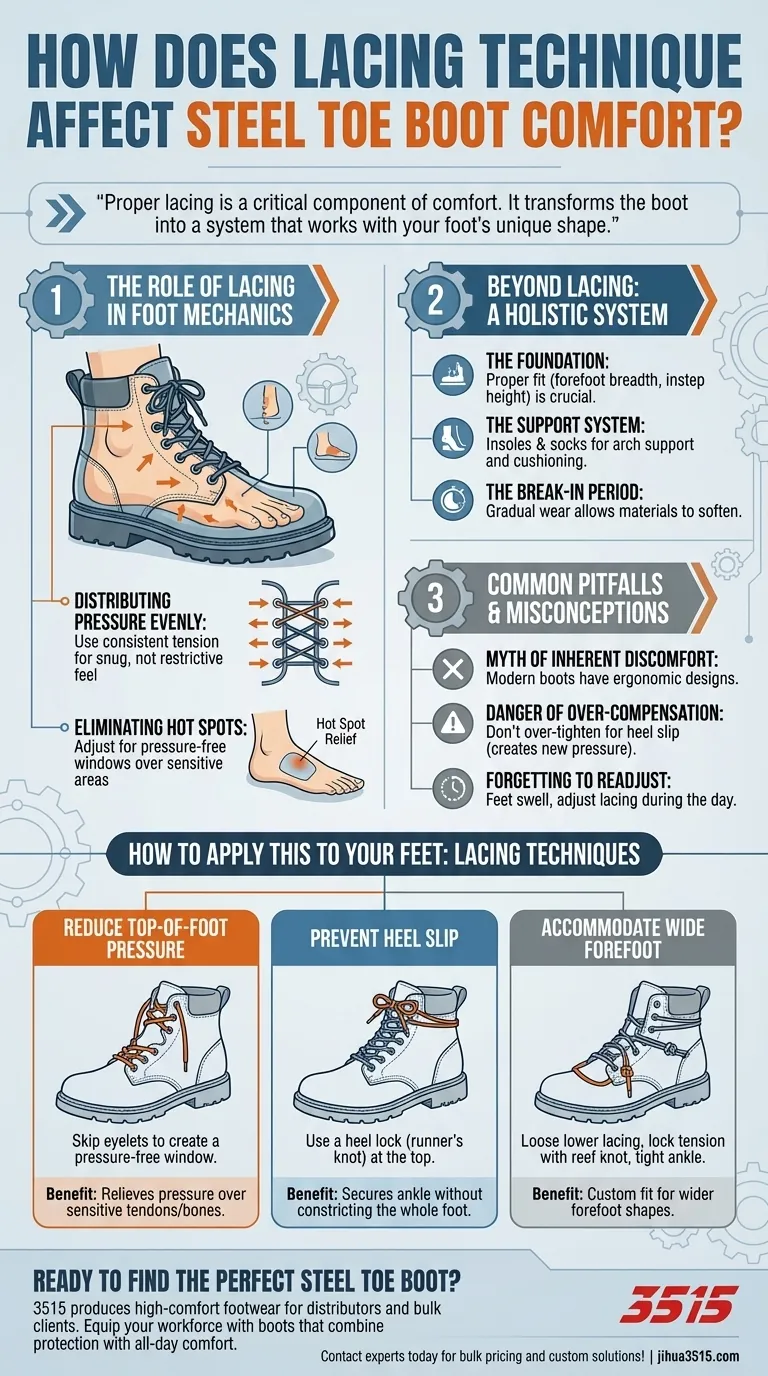

The Role of Lacing in Foot Mechanics

A steel toe boot is a rigid piece of equipment designed for protection. Lacing is the interface that customizes this rigid structure to the soft tissues and bones of your foot.

Distributing Pressure Evenly

The primary goal of any lacing pattern is to secure the boot without creating points of excessive pressure. Over-tightening any single area can restrict blood flow and lead to redness, numbness, and discomfort over a long day.

A standard crisscross pattern is effective for most, but the key is to pull the laces with consistent tension from the bottom eyelets to the top, ensuring the boot feels snug, not restrictive.

Eliminating Specific Hot Spots

If you feel a specific point of pain on the top of your foot, it's often caused by an eyelet or the tongue pressing directly on a tendon or bone. Adjusting your lacing can create a "window" or gap over that sensitive area, relieving the pressure instantly.

Beyond Lacing: A Holistic System for Comfort

While lacing is a powerful tool, it works as part of a larger system. No lacing technique can permanently fix a fundamentally flawed setup.

The Foundation: A Proper Fit

Lacing can only do so much if the boot is the wrong size or shape for your foot. Factors like forefoot breadth and the height of your instep are critical. A boot that is too narrow or shallow will cause issues that lacing cannot solve.

The Support System: Insoles and Socks

High-quality insoles or custom orthotics provide the arch support and cushioning that the boot's structure may lack. They work from the bottom up to properly position your foot inside the boot.

Likewise, moisture-wicking, cushioned socks are non-negotiable. They reduce friction, manage temperature, and provide a soft barrier between your skin and the boot's tougher materials.

The Break-In Period

Even with perfect lacing and fit, new boots require a gradual break-in period. Wear them for short durations initially, allowing the materials to soften and conform to the specific way you move.

Common Pitfalls and Misconceptions

Understanding what to avoid is just as important as knowing what to do. Many people attribute discomfort to the steel toe itself when the real culprit lies elsewhere.

The Myth of Inherent Discomfort

Modern steel toe boots have benefited from significant ergonomic advancements. The idea that they are inherently uncomfortable is outdated. With features like padded collars, lightweight materials, and better designs, comfort is now a key selling point.

The Danger of Over-Compensation

A common mistake is to aggressively over-tighten laces to compensate for a poor fit, such as heel slippage. This creates new pressure points and foot fatigue. The correct solution is often a different lacing pattern, like a heel lock, not more force.

Forgetting to Readjust

Your feet can swell slightly throughout the day. A lacing setup that feels perfect in the morning might be too tight by the afternoon. Be prepared to make minor adjustments during a break to maintain comfort.

How to Apply This to Your Feet

Your specific foot shape and comfort issues will determine the best approach. Use these recommendations as a starting point for experimentation.

- If your primary focus is reducing pressure on the top of your foot: Try skipping the eyelets directly over the painful spot to create a pressure-free window.

- If your primary focus is preventing heel slip: Use a "heel lock" (also known as a runner's knot) at the top two eyelets to securely hold your ankle in place without constricting your entire foot.

- If your primary focus is accommodating a wide forefoot: Lace the lower section of the boot more loosely and then use a reef knot to "lock" that tension before lacing the ankle section tighter.

By treating your boot lacing as an adjustable tool, you can take direct control over your daily comfort and safety.

Summary Table:

| Lacing Goal | Recommended Technique | Key Benefit |

|---|---|---|

| Reduce Top-of-Foot Pressure | Skip eyelets over painful area | Creates a pressure-free window |

| Prevent Heel Slip | Use a heel lock (runner's knot) | Secures ankle without constriction |

| Accommodate Wide Forefoot | Loose lower lacing, tight ankle | Custom fit for different foot shapes |

Ready to find the perfect steel toe boot for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-comfort footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed with advanced ergonomics for superior comfort right out of the box.

Let us help you equip your workforce with boots that combine ultimate protection with all-day comfort. Contact our experts today for bulk pricing and custom solutions!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- Why are steel toe shoes beneficial on slippery floors? Superior Traction & Fall Prevention

- How do aluminum toe boots compare to steel toe boots? Achieve Lighter Weight with Equal Protection

- What are steel-toe boots and what is their primary function? Essential Protection for Hazardous Work

- What is the primary function of Martensitic 1200 grade steel in UHSS toe caps? Achieve Slim, Lightweight Protection

- What safety standards do modern steel toe boots adhere to? Understanding ASTM & EN ISO for Maximum Protection

- What are steel toe work boots and who should wear them? Essential PPE for Hazardous Jobs

- What is the difference between safety toe and steel toe footwear? Choose the Right Protection for Your Job

- How can comfort be improved when wearing steel toe boots? A Guide to Pain-Free Workdays