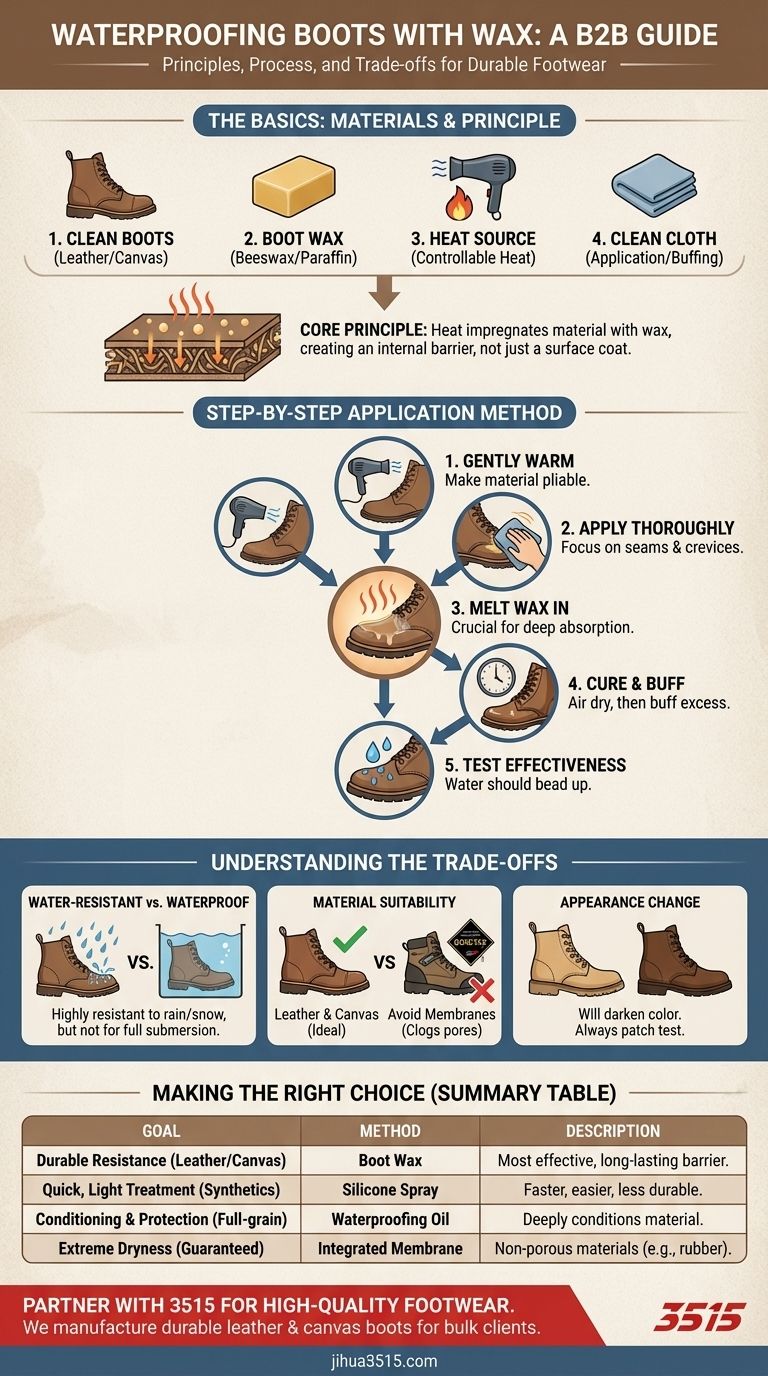

To waterproof your boots with wax, you need three basic items: the boots you intend to waterproof, a source of wax, and a heat source. For the best results, you will also want a clean cloth for application. The process involves gently warming the boot material, rubbing the wax thoroughly into all surfaces, and then using the heat source to melt the wax so it absorbs completely into the material.

The core principle of wax waterproofing is not just to coat the surface, but to use gentle heat to impregnate the material with wax, creating a durable barrier that repels water from within.

Preparing for the Process

Proper preparation is the key to an effective and long-lasting waterproof seal. Rushing these initial steps can lead to an uneven finish that wears away quickly.

Start with Clean, Dry Boots

Before applying any wax, your boots must be completely clean and dry. Dirt and moisture trapped under the wax will prevent it from adhering properly and can lead to material degradation over time.

Choose the Right Wax

You can use a simple candle or a block of paraffin wax, but a dedicated boot wax is a superior choice. These are often made from beeswax or other natural waxes formulated to condition and protect leather without being overly stiff.

Select Your Heat Source

A hair dryer is the ideal tool for this job as it provides controllable, even heat. A warm, sunny day can also work. A campfire can be used with extreme caution, but the high, uneven heat risks damaging the boot material.

Gather Your Application Tools

A simple, clean cloth or rag is perfect for applying the wax evenly. While you can rub a block of wax directly on the boot, using a cloth helps work it into seams and crevices more effectively.

The Step-by-Step Application Method

With your materials ready, the application process is straightforward. Work in a well-ventilated area and protect your workspace from wax drips.

Step 1: Gently Warm the Boots

Use your hair dryer to slightly warm the section of the boot you are about to work on. This makes the leather or canvas more pliable and helps it accept the wax more readily.

Step 2: Apply the Wax Thoroughly

Dip your cloth into the wax or rub the wax directly onto the boot. Using firm, circular motions, massage the wax into the material. Pay special attention to seams, stitching, and crevices, as these are the most common points of water entry.

Step 3: Use Heat to Melt the Wax In

After applying the wax, use your heat source to gently warm the area. You will see the wax melt and disappear as it soaks into the material. This absorption is the most critical step for creating a durable seal.

Step 4: Let It Cure and Buff

Once the entire boot is treated, let it sit and air dry completely, away from direct heat sources. After it has cured, you may notice some excess wax on the surface. Use a clean cloth to buff this off for a smooth finish.

Step 5: Test Your Work

To check the effectiveness of your waterproofing, sprinkle a few drops of water onto the boot. The water should bead up and roll off the surface. If it soaks in, that area may need a second application.

Understanding the Trade-offs

Wax is a highly effective method, but it's important to understand its characteristics and limitations before you begin.

Water Resistance vs. Waterproof

Waxing makes boots highly water-resistant, which is perfect for rain, slush, and snow. However, it does not make them fully waterproof for full submersion like a rubber boot.

Not for All Materials

This method is ideal for leather and canvas. Do not use wax on boots that already have a built-in waterproof membrane like Gore-Tex. The wax can clog the pores of the membrane, destroying its ability to breathe and release moisture from your feet.

Wax Can Alter Appearance

Applying wax will almost always darken the color of leather or canvas. Always perform a small patch test on an inconspicuous area first to see how the material will react.

Making the Right Choice for Your Boots

Your goal determines the best method for keeping your feet dry.

- If your primary focus is durable water resistance for leather or canvas: Applying a dedicated boot wax is the most effective and long-lasting choice.

- If your primary focus is a quick, light treatment for synthetic shoes: A silicone-based spray-on treatment is faster and easier, though less durable.

- If your primary focus is conditioning and protecting full-grain leather: A waterproofing oil can offer protection while deeply conditioning the material.

- If your primary focus is guaranteed dryness in extreme conditions: Purchase boots made with an integrated waterproof membrane and non-porous materials like rubber.

By choosing the right method for your specific boots and needs, you can confidently face wet conditions.

Summary Table:

| Material/Tool | Purpose & Key Consideration |

|---|---|

| Boots | Must be clean, dry, and made of leather or canvas. |

| Wax (e.g., boot wax, paraffin) | Creates a durable water-repellent barrier. Dedicated boot wax is best. |

| Heat Source (e.g., hair dryer) | Melts wax for deep absorption into the material. Provides controllable heat. |

| Clean Cloth | For even application, especially into seams and crevices. |

Need Durable, Water-Resistant Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality leather and canvas boots perfect for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable footwear designed to withstand the elements.

Partner with us to offer your customers superior products. Let's discuss how we can meet your specific needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- What are the advantages of 3/4 length arch supports for Hallux Valgus? Optimize Space and Comfort

- What role do 3-axis MEMS accelerometers play in the detection of gait abnormalities? Insights for Smart Footwear.

- How is thread size measured in textiles? A Guide to Denier for Footwear Materials

- What is the necessity of incorporating biodegradable or recycled plastic materials? Sustainable Footwear Innovation

- How do western boots prioritize comfort? Achieve All-Day Wear with Superior Foot Support

- What is the purpose of using a spring-mass model to estimate stiffness in running tests? Optimize Performance & Safety

- What shoe features suit wide feet? Find Lasting Comfort with Anatomical Design

- How should one determine the right cowboy boot toe shape for their needs? Find Your Perfect Fit for Comfort & Style