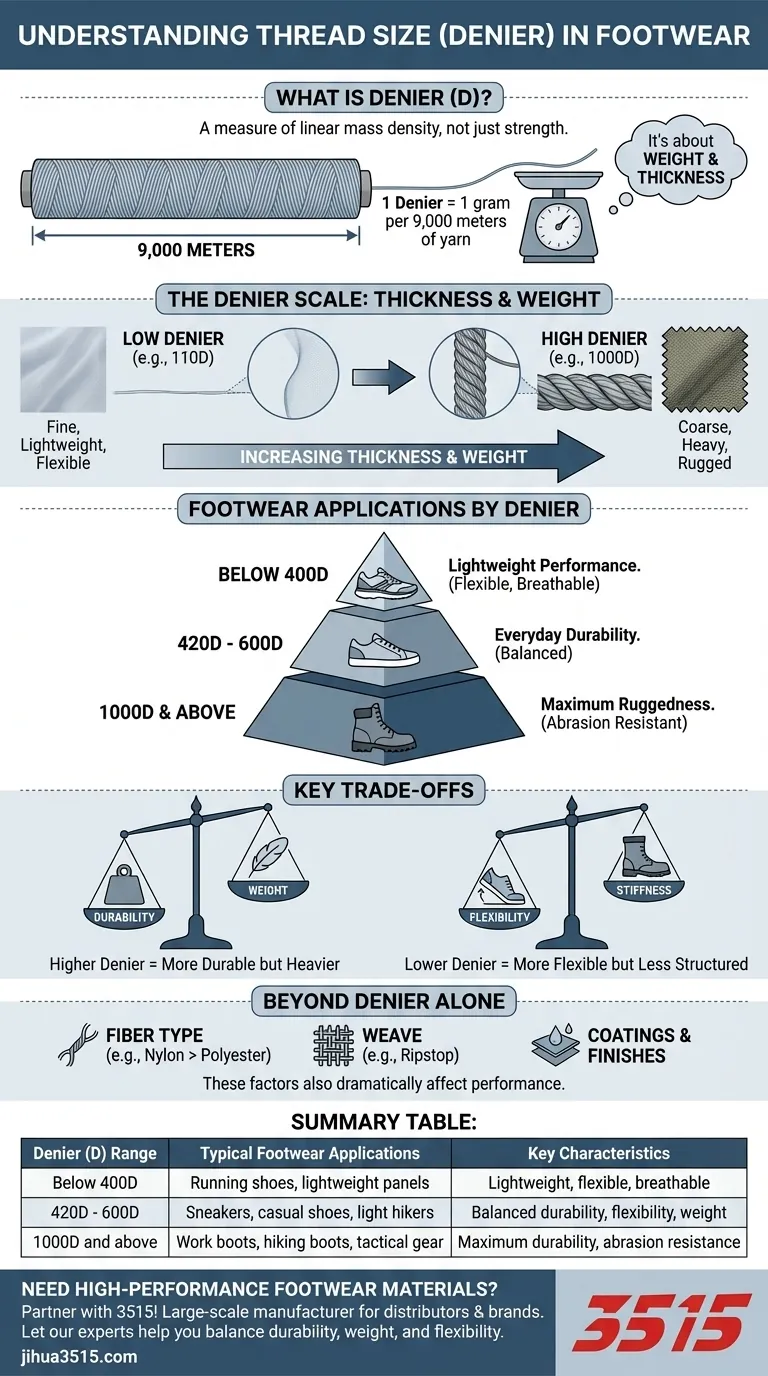

In the world of textiles, thread size is primarily measured using a unit called denier (D). This is a direct measurement of linear mass density, defined as the mass in grams of a single 9,000-meter strand of fiber. For footwear, typical values range from 420D for standard shoes to over 1000D for heavy-duty boots, indicating a significant difference in thread thickness and weight.

Denier is not a measure of strength or quality, but a simple, standardized measure of a yarn's weight and thickness. A higher denier number signifies a heavier, thicker yarn, which generally correlates with increased durability and abrasion resistance.

The Principle of Denier: Weight and Thickness

Understanding denier begins with grasping its simple, weight-based definition. It's a system designed for consistency across different material types.

The 9,000-Meter Standard

The formal definition is straightforward: 1 denier = 1 gram per 9,000 meters of yarn. This means if you had a 9-kilometer-long strand of a fiber and it weighed 500 grams, it would be classified as 500D.

Higher Denier = Thicker Thread

The most critical takeaway is the direct relationship between the number and the physical yarn. A 1000D yarn is significantly thicker and heavier than a 420D yarn. This has a direct impact on the resulting fabric's properties.

Visualizing the Difference

Think of 110D as being similar to a very fine, lightweight lining fabric. In contrast, 1000D fabric is coarse and rugged, often used for military-grade bags and the toughest parts of a work boot.

Denier in Practice: Matching Material to Application

The denier value of a fabric is a primary indicator of its intended use. Different applications demand different balances between durability and weight.

Lightweight Applications (e.g., 110D)

Low-denier fabrics are chosen when minimizing weight is the top priority. You will find them in ultralight jackets, tent flies, and internal linings where abrasion is not a major concern.

General Footwear (420D - 600D)

This is the sweet spot for a wide range of everyday shoes, from sneakers to light hikers. Fabrics in this range, often made of nylon, provide a good balance of durability for daily wear without being excessively heavy or rigid.

Heavy-Duty Gear (1000D+)

When maximum durability and abrasion resistance are non-negotiable, high-denier fabrics are the standard. This is the domain of tactical gear, luggage, and heavy-duty work or hiking boots designed for harsh environments.

Understanding the Trade-offs

Choosing a material based on denier is always a matter of balancing competing priorities. A higher denier is not universally "better."

Durability vs. Weight

This is the fundamental trade-off. The toughness of a 1000D fabric comes at the cost of significant weight compared to a 420D alternative. For an athlete, that extra weight is a penalty; for a construction worker, it's a necessity.

Flexibility and Feel

Higher-denier fabrics are inherently stiffer due to their thicker yarns. This can provide structure but may reduce comfort and flexibility in footwear that needs to bend with the foot.

Beyond Denier Alone

It is critical to remember that denier is just one piece of the puzzle. The type of fiber (nylon is generally more abrasion-resistant than polyester), the weave of the fabric (e.g., a ripstop weave adds tear resistance), and any coatings or finishes all dramatically affect the final performance.

Making the Right Choice for Your Footwear

Use denier as a primary guide to narrow your material selection based on your product's core purpose.

- If your primary focus is lightweight performance (e.g., running shoes): You will likely work with lower denier fabrics (below 400D) in specific panels, prioritizing breathability and minimal weight.

- If your primary focus is everyday durability (e.g., sneakers, casual shoes): The 420D to 600D range offers the ideal balance of abrasion resistance and flexibility for common use.

- If your primary focus is maximum ruggedness (e.g., work boots, hiking boots): Target high-denier fabrics (1000D or more), especially in high-wear areas like the heel and toe cap.

Understanding denier empowers you to select materials with precision, perfectly aligning fabric properties with product performance.

Summary Table:

| Denier (D) Range | Typical Footwear Applications | Key Characteristics |

|---|---|---|

| Below 400D | Running shoes, lightweight panels | Lightweight, flexible, breathable |

| 420D - 600D | Sneakers, casual shoes, light hikers | Balanced durability, flexibility, and weight |

| 1000D and above | Work boots, hiking boots, tactical gear | Maximum durability, abrasion resistance, ruggedness |

Need High-Performance Footwear Materials? Partner with 3515!

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, using the right denier materials for optimal performance—from lightweight 420D for everyday sneakers to rugged 1000D+ for heavy-duty boots.

Let us help you select the perfect materials to balance durability, weight, and flexibility for your target market. Contact our experts today to discuss your footwear manufacturing needs!

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What should be considered when choosing sneakers for a business casual office look? Achieve Comfort & Professionalism

- Can sneakers be part of a business casual wardrobe? Yes, with the right style and fit

- What are the key features of high-quality leather in shoes? Invest in Durability and a Perfect Fit

- Can trainers/sneakers be worn in a business casual setting? How to Choose the Right Style for a Professional Look

- Are sneakers acceptable in a business casual workplace? How to Choose the Right Style