The primary advantage of steel toe boots is their exceptional and time-tested protection against impact and crushing injuries at a lower cost. However, their main disadvantages are their heavy weight, poor temperature insulation, and their conductivity, which makes them unsuitable for certain electrical hazard environments.

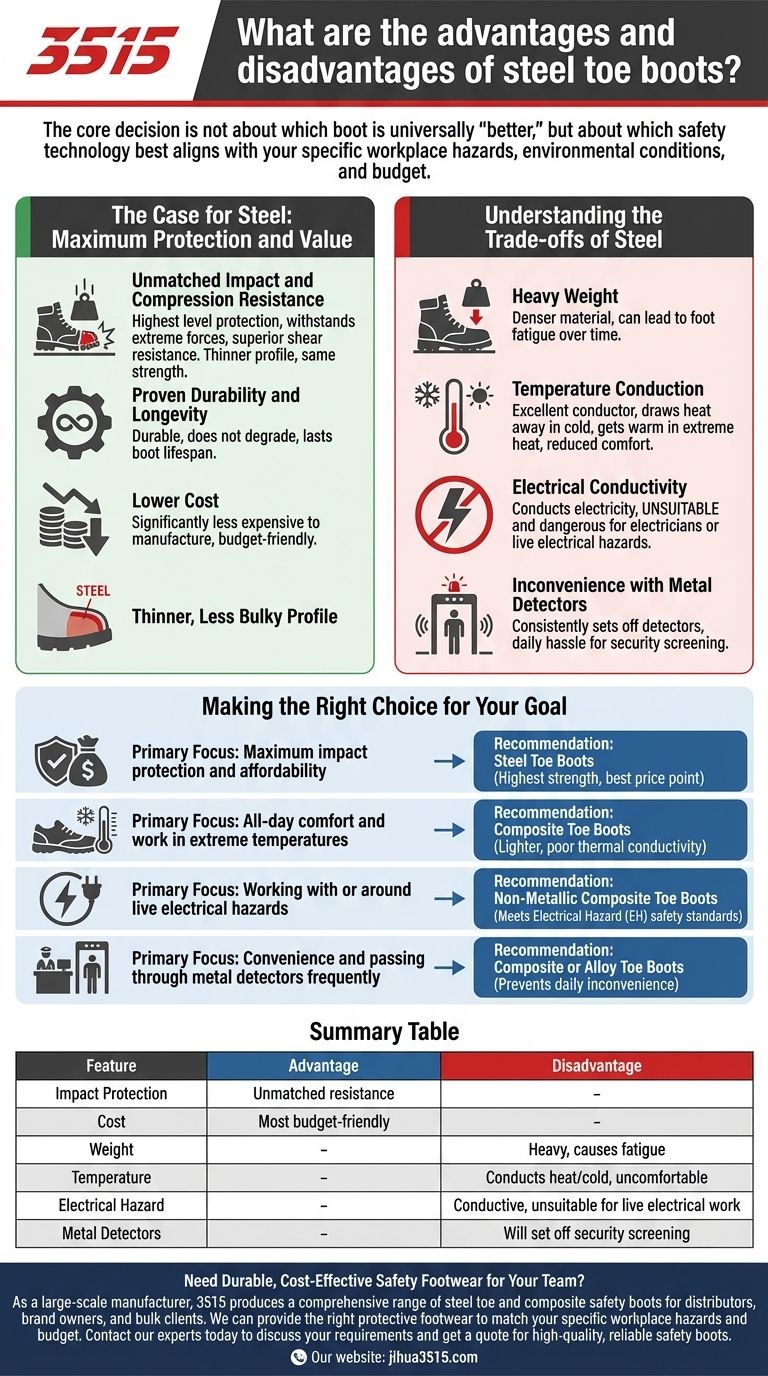

The core decision is not about which boot is universally "better," but about which safety technology best aligns with your specific workplace hazards, environmental conditions, and budget. Steel remains the benchmark for pure impact protection, but its properties create significant trade-offs.

The Case for Steel: Maximum Protection and Value

Steel toe boots are the traditional standard for a reason. Their core strength lies in their ability to withstand extreme forces, providing a reliable barrier against common workplace hazards.

Advantage: Unmatched Impact and Compression Resistance

Steel offers the highest level of protection against impact and compression. It can withstand heavier falling objects and greater crushing forces than other materials, a critical feature when working around heavy machinery or materials.

This strength also provides superior shear resistance, protecting against objects that might slice or cut through the toe cap.

Advantage: Proven Durability and Longevity

Steel is an incredibly durable material. A steel toe cap will not degrade over time and is built to last the entire lifespan of the boot itself, providing consistent, reliable protection day after day.

Advantage: Lower Cost

Compared to modern alternatives like composite or alloy toes, steel is significantly less expensive to manufacture. This cost-saving is passed on to the consumer, making steel toe boots the most budget-friendly option for meeting safety standards.

Advantage: Thinner, Less Bulky Profile

Because of its inherent strength, a steel toe cap can be made thinner than a composite one while still providing the same or higher level of impact resistance. This results in a less bulky, more streamlined toe box within the boot.

Understanding the Trade-offs of Steel

While steel excels in protection and cost, its physical properties introduce several practical disadvantages that are critical to consider for daily wear and specific environments.

Disadvantage: Heavy Weight

The most noticeable drawback of steel toe boots is their weight. Steel is denser than composite materials, and this added weight can lead to foot fatigue and reduced comfort over a long workday.

Disadvantage: Temperature Conduction

Steel is an excellent conductor of temperature. In cold environments, the steel cap will draw heat away from your feet, making them feel colder. Conversely, in extreme heat, the steel can become warm, reducing overall comfort.

Disadvantage: Electrical Conductivity

This is a critical safety consideration. Steel conducts electricity, making standard steel toe boots unsuitable and dangerous for electricians or anyone working in environments with a significant live electrical hazard.

While Electrical Hazard (EH) rated boots exist, the conductive nature of steel itself presents an inherent risk that non-metallic options avoid entirely.

Disadvantage: Inconvenience with Metal Detectors

The steel cap will consistently set off metal detectors. This can be a daily hassle for workers who must pass through security checkpoints, such as at airports, government buildings, or secure industrial facilities.

Making the Right Choice for Your Goal

Selecting the right safety boot requires matching its features to your specific job requirements.

- If your primary focus is maximum impact protection and affordability: Steel toe boots offer the highest level of strength against crushing and impact forces at the most accessible price point.

- If your primary focus is all-day comfort and you work in extreme temperatures: The lighter weight and poor thermal conductivity of a composite toe boot will likely be a better fit.

- If your primary focus is working with or around live electrical hazards: You should avoid standard steel toe boots and opt for a non-metallic composite toe that meets Electrical Hazard (EH) safety standards.

- If your primary focus is convenience and you pass through metal detectors frequently: A composite or alloy toe boot will prevent the daily inconvenience of triggering security screening.

Ultimately, understanding the specific risks of your environment is the key to choosing footwear that provides the right protection without unnecessary compromise.

Summary Table:

| Feature | Advantage | Disadvantage |

|---|---|---|

| Impact Protection | Unmatched resistance to crushing and impact | - |

| Cost | Most budget-friendly safety toe option | - |

| Weight | - | Heavy, can cause foot fatigue |

| Temperature | - | Conducts heat/cold, uncomfortable in extremes |

| Electrical Hazard | - | Conductive, unsuitable for live electrical work |

| Metal Detectors | - | Will set off security screening |

Need Durable, Cost-Effective Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and composite safety boots for distributors, brand owners, and bulk clients. We can provide the right protective footwear to match your specific workplace hazards and budget.

Contact our experts today to discuss your requirements and get a quote for high-quality, reliable safety boots.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- What are the benefits of wearing steel toe work boots beyond foot protection? Enhanced Durability, Comfort & Cost Savings

- What protection do steel toe boots provide? Essential Safety for Hazardous Work

- Are steel toe shoes unsafe for electricians? Debunking the EH-Rated Footwear Myth

- Why is it necessary to conduct mechanical strength evaluations on polycarbonate toecaps? Ensure Impact Safety & Comfort

- Why is a composite toe preferable to a steel toe in winter boots? Superior Insulation & Warmth

- What are the alternatives to steel toe boots for safety? Discover Lighter, Safer Options

- What daily practices can enhance foot comfort when wearing steel toe boots? Create a Comfortable Foundation for Your Workday