For winter conditions, the primary advantage is thermal. A composite toe is preferable to a steel toe in winter boots because its non-metallic materials, such as Kevlar, carbon fiber, or plastic, do not conduct cold. Unlike steel, which actively draws heat away from your foot and can make your toes feel frigid, a composite toe acts as an insulator, helping you stay warm while meeting the same official safety standards.

The choice between composite and steel toes is a strategic trade-off. While composite offers superior comfort in extreme temperatures and electrical hazard environments, steel provides the absolute maximum resistance to crushing impacts and punctures.

The Core Difference: Thermal Conduction

How Steel Toes Act in the Cold

Steel is a highly efficient thermal conductor. This means it rapidly transfers heat energy.

In winter, a steel toe cap will absorb the cold from the environment and transfer it directly to your foot, effectively pulling your body heat out of the boot. This can lead to significant discomfort and even risk in freezing conditions.

Why Composite Toes Excel in Winter

Composite materials are poor thermal conductors, meaning they are excellent insulators.

They create a barrier that prevents the outside cold from penetrating the boot and stops your body heat from escaping. This thermal insulation is the single biggest reason composite toes are superior for winter wear.

Beyond Winter: Key Distinctions

Material Composition and Weight

Steel toe caps are just that—a heavy piece of steel. They offer proven protection but add significant weight to the boot, which can cause fatigue over a long day.

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. They are significantly lighter than steel, often meeting the same safety standards at half the weight, which enhances all-day comfort.

Electrical Hazard (EH) Protection

Because composite toes contain no metal, they do not conduct electricity.

This makes them the only safe choice for electricians or anyone working in environments where accidental contact with a live electrical circuit is a risk. Steel, a natural conductor, presents a serious danger in these situations.

Convenience at Checkpoints

The non-metallic and non-magnetic nature of composite toes means they will not set off metal detectors.

This is a major convenience for workers who must pass through security checkpoints frequently, saving time and hassle.

Understanding the Trade-offs

Impact Resistance

Both composite and steel toe boots must meet the same ASTM F2413-18 standard for impact and compression resistance. They are both safe for most job sites.

However, steel has a higher breaking point. Under an extreme impact that exceeds the ASTM standard, a composite toe may crack or shatter, while steel is more likely to bend. For environments with exceptional crushing hazards, steel offers a higher margin of safety.

Puncture and Cut Resistance

Steel's inherent strength gives it a general advantage against punctures or cuts from sharp, heavy objects. While the boot's sole provides primary puncture protection, the steel cap itself is more durable against these types of hazards.

Making the Right Choice for Your Work

Ultimately, the best choice depends entirely on your specific work environment and priorities.

- If your primary focus is working in cold weather or around electrical hazards: Composite toe is the definitive choice for its thermal insulation and non-conductive properties.

- If your primary focus is all-day comfort and reduced fatigue: The lighter weight of composite toe boots will make a significant difference over a long shift.

- If your primary focus is maximum protection against extreme crushing impacts: Steel toe remains the superior option for its ultimate strength in high-risk environments like heavy construction or logging.

Choosing the right safety toe is about aligning the material's inherent properties with the specific demands of your job.

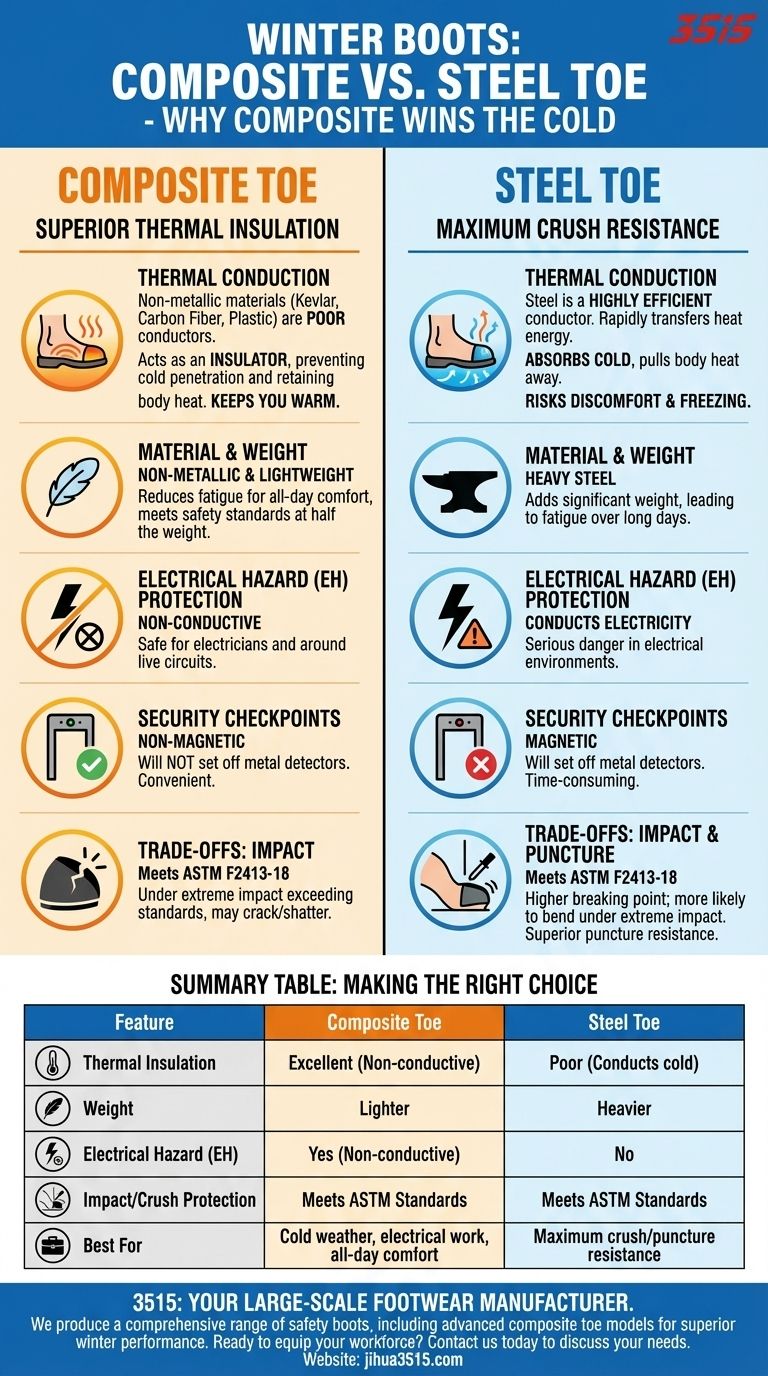

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Thermal Insulation | Excellent (Non-conductive) | Poor (Conducts cold) |

| Weight | Lighter | Heavier |

| Electrical Hazard (EH) Rating | Yes (Non-conductive) | No |

| Impact/Crush Protection | Meets ASTM Standards | Meets ASTM Standards |

| Best For | Cold weather, electrical work, all-day comfort | Maximum crush/puncture resistance |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, including advanced composite toe models designed for superior winter performance and comfort.

Ready to equip your workforce with the right safety footwear? Contact us today to discuss your needs and discover how our reliable, high-quality boots can enhance safety and productivity for your customers.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What are the characteristics of a steel toe? Maximum Impact Protection Explained

- What are the benefits of anti-fatigue mats for steel toe boot wearers? A Guide to Managing Workplace Comfort

- What are the key differences between steel toe and composite toe boots? A Guide to Choosing the Right Safety Footwear

- What are steel toe work boots and what is their primary purpose? Essential Foot Protection for Hazardous Work

- What is the myth about steel-toe boots, and is it true? Debunking the Amputation Risk

- What are the recommended uses for steel toe safety shoes? Essential Protection for High-Risk Industries

- How should you properly break in new steel toe boots? A 3-Phase Guide for Lasting Comfort

- How much weight can steel toe boots typically withstand? 2,500 lbs of Crush Protection Explained