The most significant damage to your work boots often stems from seemingly harmless daily habits. You can drastically extend their life by avoiding three common mistakes: kicking them off without unlacing, stomping into them to put them on, and using the toe of the boot as a tool to kick or lift objects.

The key to extending the life of your work boots is a two-part strategy: eliminate the daily habits that break down the boot's structure and implement a proactive conditioning routine before they ever see the job site.

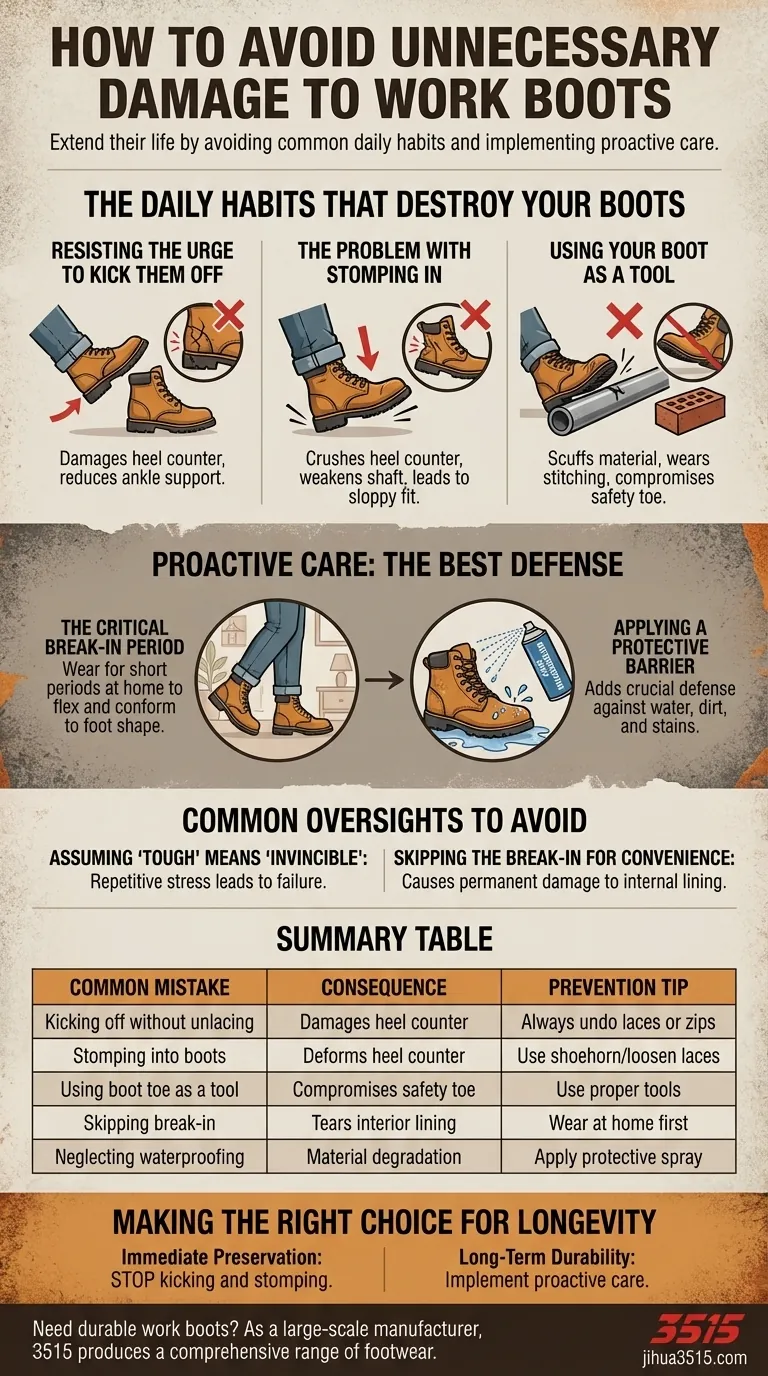

The Daily Habits That Destroy Your Boots

The most severe wear and tear on work boots doesn't always come from the job site itself, but from how you put them on and take them off. These small, repetitive actions can compromise the boot's structural integrity faster than any external hazard.

Resisting the Urge to Kick Them Off

Using one foot to hold down the heel of the other boot to kick it off places immense stress on the heel counter. This is the stiff, internal component that cups your heel.

Damaging the heel counter ruins the boot's fit, reduces critical ankle support, and leads to premature failure of the entire structure. Always take a moment to undo the laces or zips.

The Problem with Stomping In

Forcing your foot into a boot by stomping down crushes the same heel counter from the inside. It can also damage and weaken the boot's shaft.

This habit permanently deforms the supportive structure, leading to a sloppy fit and diminished protection over time.

Using Your Boot as a Tool

Your work boots are personal protective equipment, not a hammer or a pry bar. Using the toe to kick, nudge, or lift heavy, abrasive, or sharp objects is a common but destructive habit.

This action scuffs and gouges the material, wears down the stitching, and can even compromise the integrity of the safety toe, whether it's made of steel, composite, or alloy.

Proactive Care: The Best Defense

Avoiding bad habits is only half the battle. A few preparatory steps with a new pair of boots create a foundation for a much longer lifespan.

The Critical Break-In Period

Before you ever wear your boots on the job, it's essential to break them in. Wearing them for short periods around the house allows the materials to flex and conform to your foot's shape.

This prevents the harsh stresses of a worksite from causing immediate tears in the interior lining, ensuring both comfort and durability from day one.

Applying a Protective Barrier

Once broken in, applying a quality waterproofing spray adds a crucial layer of defense. This treatment creates an invisible barrier that does more than just repel water.

It also helps fend off dirt and stains, which can degrade materials like leather, suede, nubuck, and textiles over time. This simple step keeps the boot's upper material in better condition for longer.

Common Oversights to Avoid

Trusting a boot's rugged construction without providing basic care is a common and costly mistake. Understanding these oversights can save you from replacing your boots prematurely.

Assuming 'Tough' Means 'Invincible'

Work boots are built to be durable, but they are not indestructible. The small, repetitive stresses from improper use, like kicking objects, accumulate over time.

This gradual degradation weakens seams, abrades materials, and ultimately leads to failure.

Skipping the Break-In for Convenience

The desire to use new gear immediately is understandable, but skipping the break-in period is a significant oversight.

You trade a few hours of initial inconvenience for long-term discomfort and the high probability of causing permanent damage to the boot's internal lining.

Making the Right Choice for Longevity

Your approach to boot care directly impacts how long your investment lasts. Tailor your focus based on your primary goal.

- If your primary focus is immediate preservation: Stop kicking your boots off and stomping into them today; these are the fastest ways to break down their core structure.

- If your primary focus is long-term durability: Implement a proactive care routine by properly breaking in new boots and applying a protective treatment before their first use on site.

By treating your boots with the same respect as any other critical tool, you ensure they protect you effectively for years to come.

Summary Table:

| Common Mistake | Consequence | Prevention Tip |

|---|---|---|

| Kicking boots off without unlacing | Damages heel counter, reduces ankle support | Always undo laces or zips before removal |

| Stomping into boots | Deforms heel counter, weakens shaft | Use a shoehorn or loosen laces fully |

| Using boot toe as a tool | Scuffs material, compromises safety toe | Use proper tools for kicking or lifting objects |

| Skipping break-in period | Tears interior lining, causes discomfort | Wear boots at home before worksite use |

| Neglecting waterproofing | Material degradation from water and dirt | Apply protective spray after break-in |

Need durable work boots that stand the test of time? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and work boots designed with longevity in mind. Contact us today to discuss how our durable footwear solutions can protect your workers and your budget.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the top 5 must-have features in firefighting boots? Essential Guide for Firefighter Safety

- What are pull straps and their variations in cowboy boots? A Guide to Mule Ears, Flush Pulls & More

- How can proper care extend the lifespan of work boots? Maximize Durability & Safety

- What makes moc toe boots suitable for work environments? Unmatched Comfort & Durability

- Why is it important to care for farm boots? Protect Your Investment and Safety on the Job

- What is the function of a shank in work boots? The Hidden Support System Explained

- What is a recommended style for cowboy boots? Find Your Perfect Fit for Style & Function

- How should calf circumference be measured for boots? Ensure a Perfect, Comfortable Fit