The shank is the invisible backbone of a quality work boot. It is a stiff, supportive strip made of steel, composite, or nylon that is embedded between the insole you stand on and the midsole of the boot. Its primary function is to provide structural rigidity under the arch of your foot, distributing your weight and reducing strain when climbing, carrying heavy loads, or navigating uneven terrain.

The shank transforms a simple boot into a stable work platform. By preventing the boot from flexing or collapsing under your arch, it provides crucial support that reduces fatigue in your feet, calves, and back over a long workday.

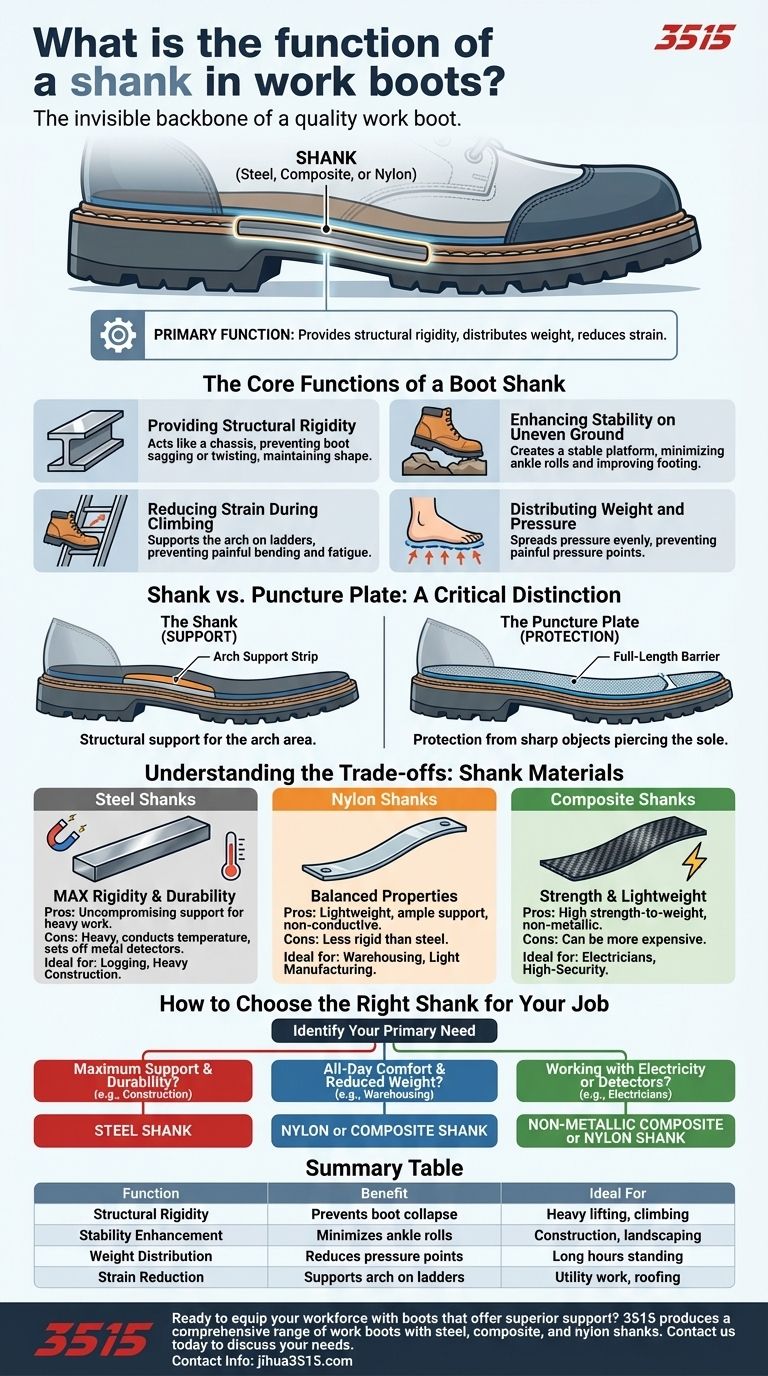

The Core Functions of a Boot Shank

A shank's role goes far beyond simple stiffness. It is an engineered component designed to enhance both safety and comfort in specific, measurable ways.

Providing Structural Rigidity

Think of the shank as the chassis of a vehicle. It creates a rigid structure that prevents the boot from sagging or twisting under your body weight.

This foundational support is what maintains the boot's shape and integrity over time, ensuring it continues to support you correctly.

Enhancing Stability on Uneven Ground

When walking on rocks, rebar, or rough terrain, your foot can easily twist. A shank creates a stable, unyielding platform under your foot.

This rigidity minimizes the risk of ankle rolls and provides a confident footing, allowing you to focus on the task at hand.

Reducing Strain During Climbing

For anyone who uses ladders, the shank is a critical safety feature. It bridges the gap across the ladder rung, supporting your entire arch.

Without a shank, your foot would be forced to bend unnaturally around the rung, causing intense pain and rapid fatigue in your arches and calf muscles.

Distributing Weight and Pressure

The shank helps distribute pressure evenly across the bottom of your foot. This prevents the concentration of force on your heel and the ball of your foot.

This even distribution is key to all-day comfort, preventing the development of painful pressure points and general foot soreness.

Shank vs. Puncture Plate: A Critical Distinction

It's common to confuse a shank with a puncture-resistant plate, but they serve two entirely different purposes. Understanding the difference is essential for your safety.

The Shank is for Support

A shank’s job is purely structural. It is a relatively narrow strip designed to provide rigidity and support specifically to the arch area.

The Puncture Plate is for Protection

A puncture plate is a full-length sheet of steel or composite fabric built into the sole to stop sharp objects like nails from piercing the boot and injuring your foot. While many heavy-duty boots contain both, their functions do not overlap.

Understanding the Trade-offs: Shank Materials

The material used for the shank directly impacts the boot's weight, flexibility, and performance characteristics.

Steel Shanks

This is the traditional, heavy-duty option. Steel provides the maximum rigidity and durability, making it ideal for the most demanding jobs like logging or heavy construction.

However, steel is heavy and will conduct heat and cold, which can be a drawback in extreme temperatures. It will also set off metal detectors.

Nylon Shanks

A more modern and common alternative, nylon offers a great balance of properties. It provides ample support for most jobs while being significantly lighter than steel.

Nylon doesn't have the absolute rigidity of steel, but it is more than sufficient for general use and won't conduct temperature.

Composite Shanks

Composite shanks are made from materials like fiberglass, carbon fiber, or TPU. They offer strength and support that can rival steel but at a fraction of the weight.

They are also non-metallic, making them the superior choice for electricians or anyone working in high-security environments with metal detectors.

How to Choose the Right Shank for Your Job

Selecting the right shank material depends entirely on your daily tasks and work environment.

- If your primary focus is maximum support and durability (e.g., construction, logging): A steel shank provides the uncompromising rigidity needed for heavy-duty work and the most uneven terrain.

- If your primary focus is all-day comfort and reduced weight (e.g., warehousing, light manufacturing): A nylon or composite shank offers excellent support without the fatigue caused by a heavier boot.

- If your primary focus is working around electricity or metal detectors (e.g., electricians, airport staff): A non-metallic composite or nylon shank is essential for safety and convenience.

Understanding the shank moves you from simply buying a boot to investing in the right tool for your feet.

Summary Table:

| Function | Benefit | Ideal For |

|---|---|---|

| Structural Rigidity | Prevents boot from collapsing under arch | Heavy lifting, climbing |

| Stability Enhancement | Minimizes risk of ankle rolls on rough terrain | Construction, landscaping |

| Weight Distribution | Reduces pressure points and foot fatigue | Long hours standing, walking |

| Strain Reduction | Supports foot during ladder climbing | Utility work, roofing |

Ready to equip your workforce with boots that offer superior support and reduce fatigue?

As a large-scale manufacturer, 3515 produces a comprehensive range of work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, including models with steel, composite, and nylon shanks tailored to your specific job requirements—from heavy construction to electrical work.

Contact us today to discuss your needs and discover how 3515 can be your reliable partner in safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do work boots protect against common construction hazards? A Guide to Essential Foot Safety

- How do work boots support ankles? Essential Features for Injury Prevention

- What were the consequences of using traditional leather treatments on firefighter boots? Avoid Premature Dry Rot & Cracking

- Why are ergonomic design and comfort critical for safety boot compliance? Boost Worker Safety and Adoption Rates

- Why is waterproofing important in work boots? Protect Your Feet from Moisture, Injury, and Cold

- What are the key features of logger boots? A Guide to Unmatched Stability & Safety

- What are the conductive properties requirements in ASTM standards? A Guide to CD vs. SD Footwear

- What role have influencers played in the recent popularity of moc toe boots? The Modern Megaphone for a Timeless Style