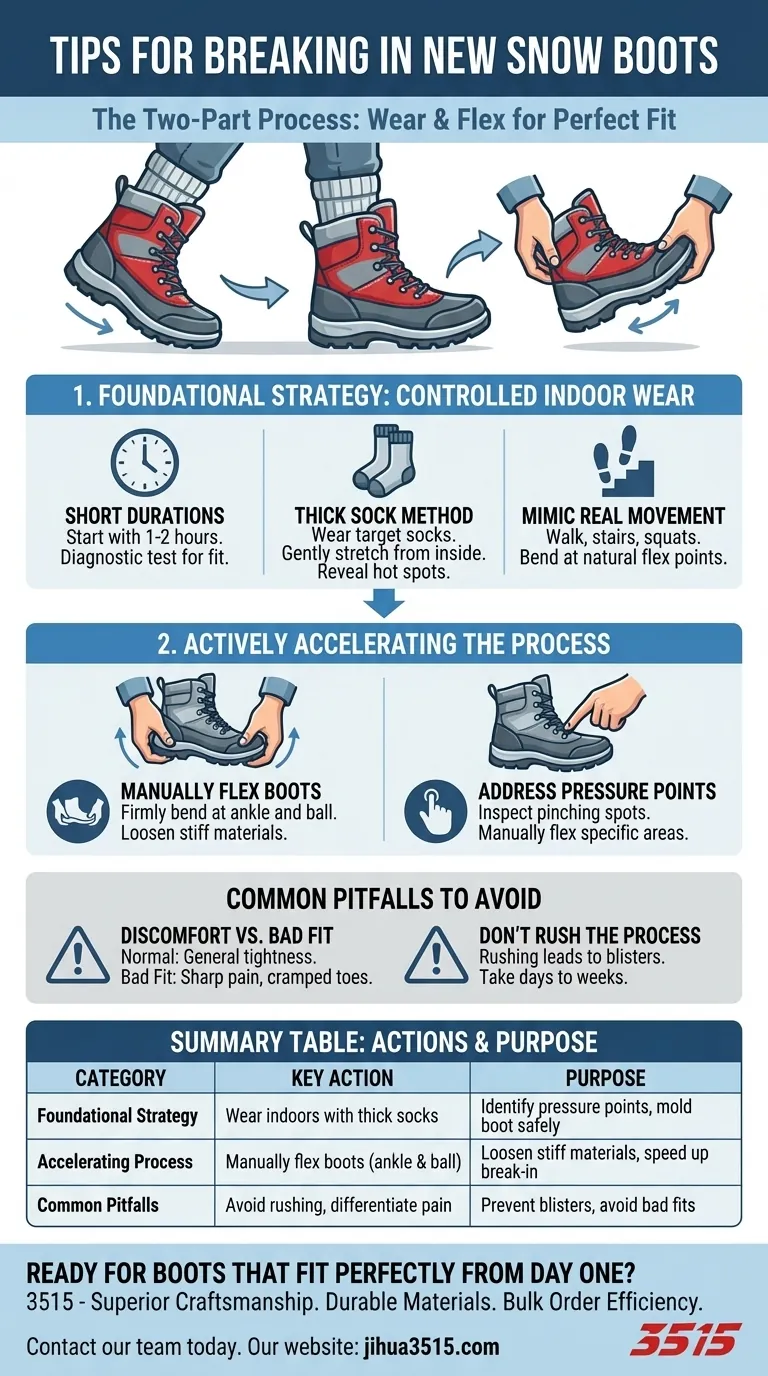

The most effective way to break in new snow boots is through a simple, two-part process. You should wear them around your house for short, controlled periods with thick socks and supplement this with manually flexing the boots to soften their stiffest points. This combination safely molds the boot to your foot without the risk of blisters on the trail.

Breaking in new snow boots is not about forcing them to fit, but about patiently encouraging their rigid materials to conform to the unique shape and movement of your feet. The goal is to simulate real-world wear in a low-stakes environment, ensuring comfort and preventing pain when you truly need them.

The Foundational Strategy: Controlled Indoor Wear

The primary goal of the break-in period is to identify and resolve any comfort issues before you are miles away from home. Wearing your boots indoors is the safest way to do this.

Start with Short Durations

Begin by wearing your new boots around the house for just one or two hours at a time. This initial period is a diagnostic test to confirm the fit is correct and to introduce your feet to the new environment.

Use the Thick Sock Method

Always wear the same type of thick, warm socks you plan to use in the snow. Wearing one or even two pairs of thick socks helps gently stretch the boot material from the inside and more quickly reveals potential "hot spots" or pressure points.

Mimic Real Movement

Don’t just sit in the boots. Walk around your home, go up and down stairs, and do a few squats. These movements force the boot to bend at its natural flex points, specifically at the ankle and the ball of your foot, which is critical for the break-in process.

Actively Accelerating the Process

While passive wear is effective, you can speed things up by actively working the boot's materials.

Manually Flex the Boots

When you're not wearing the boots, take time to work them with your hands. Firmly bend the boot back and forth at the ankle. Roll and crease the area over the ball of the foot. This helps loosen the leather or synthetic fibers, making them more pliable.

Address Pressure Points Immediately

If you feel a specific spot rubbing or pinching during your indoor wear sessions, take the boots off and inspect the area. Manually flexing that specific part of the boot can help soften it.

Common Pitfalls to Avoid

Understanding what not to do is as important as knowing what to do. A mistake during the break-in period can lead to discomfort or even damage your investment.

Differentiating Discomfort from a Bad Fit

It is crucial to know the difference between normal stiffness and a fundamental fit problem. General tightness and rigidity are normal and will lessen over time. However, sharp, pinching pain or your toes being cramped against the end of the boot are signs of a poor fit that breaking in cannot fix.

Don't Rush the Process

The break-in period can take anywhere from a few days to a couple of weeks, depending on the stiffness of the boot's materials. Rushing this by wearing them on a long, demanding hike prematurely is the most common cause of painful blisters.

Making Your Boots Trail-Ready

Use your break-in goal to guide your approach.

- If your primary focus is a perfect long-term fit: Use the slow and steady indoor wear method over one to two weeks, gradually increasing the duration each day.

- If your primary focus is getting them ready for an upcoming trip: Combine several short indoor wear sessions per day with frequent manual flexing of the boots' ankle and toe-box areas.

- If your primary focus is avoiding injury: Pay close attention to any sharp or pinching pain, which indicates a sizing or shape issue that requires you to exchange the boots.

Properly breaking in your boots is the foundational step to ensuring comfort and confidence on any winter adventure.

Summary Table:

| Tip Category | Key Action | Purpose |

|---|---|---|

| Foundational Strategy | Wear boots indoors with thick socks for short periods. | Identify pressure points and mold the boot safely. |

| Accelerating the Process | Manually flex the boots at the ankle and ball of the foot. | Loosen stiff materials and speed up the break-in. |

| Common Pitfalls | Avoid rushing the process; differentiate discomfort from a bad fit. | Prevent blisters and avoid boots that will never fit correctly. |

Ready for Boots That Fit Perfectly from Day One?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our expertise ensures that every pair of snow boots is crafted with attention to detail, using materials that balance durability with comfort.

We help you avoid the break-in hassle by providing:

- Superior Craftsmanship: Boots designed for optimal fit and performance.

- Durable Materials: Selected for comfort and long-lasting wear.

- Bulk Order Efficiency: Reliable supply for your business needs.

Let’s discuss how our production capabilities can meet your specific requirements.

Contact our team today to explore our catalog and find the perfect footwear solution for your customers.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the benefits of choosing stylish yet protective motorcycle boots? Ride Safe Without Sacrificing Style

- How does the use of high-performance technical fabrics improve the quality perception of outdoor and safety footwear?

- What are alpine boots designed for? The Essential Guide to Downhill Skiing Footwear

- What construction features enhance motorcycle boot durability? Key Features for Long-Lasting Gear

- What are the key features to look for in gardening shoes? Find Durable, Waterproof & Comfortable Footwear

- What features should hunting boots for mountainous terrain have? Essential Stability for Steep Hunts

- What is shock absorption in winter boots and why is it important? Essential for Comfort & Joint Health

- What are the characteristics of good fishing boots? Find the Perfect Boot for Your Fishing Style