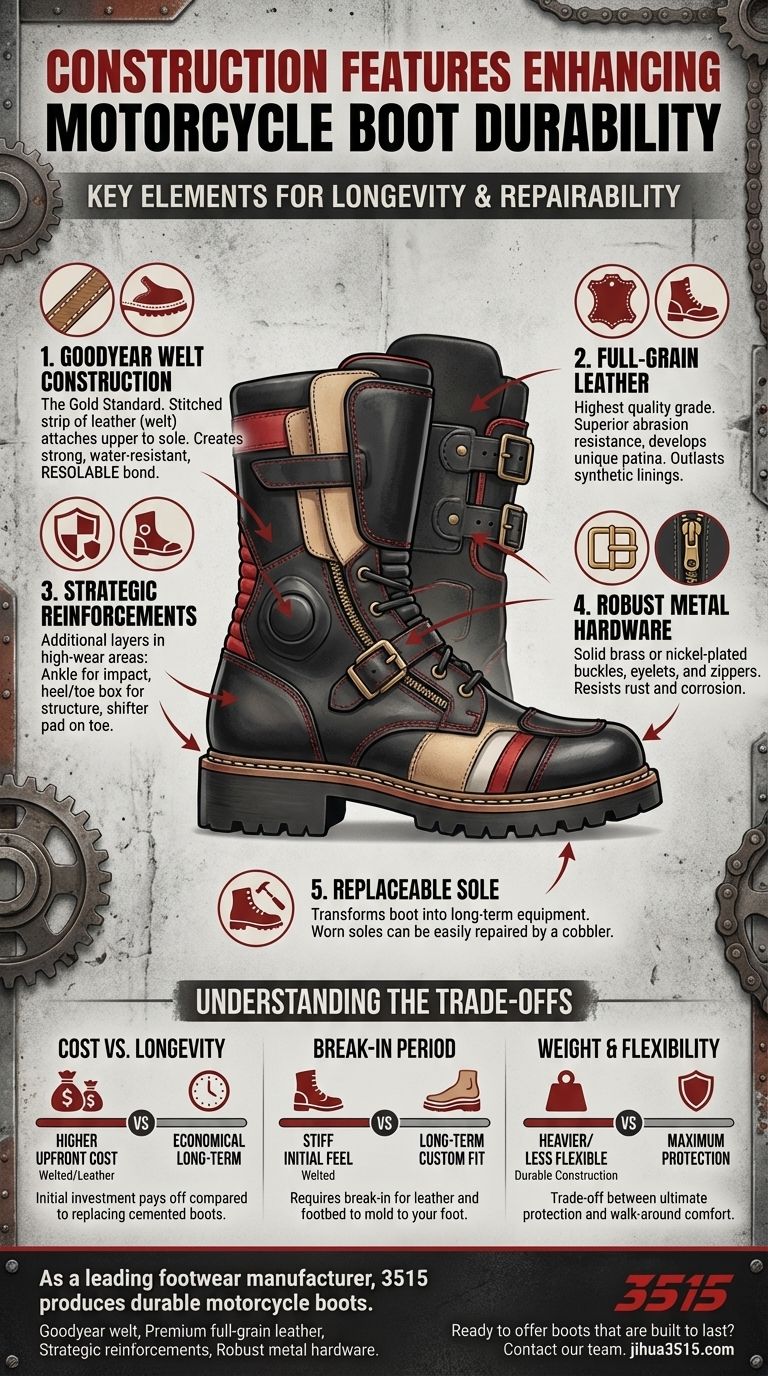

At its core, a durable motorcycle boot is defined by five key features: a stitched sole construction like a Goodyear welt, the use of high-quality leather, strategic reinforcements at high-wear areas, robust metal hardware, and the ability to be resoled. These elements work together to create a boot that is not just tough, but fundamentally repairable for a long service life.

The most significant distinction between a durable, long-lasting boot and a disposable one lies in its construction. A boot with a stitched, replaceable sole is an investment in gear that can be maintained and rebuilt for years, while a glued sole often marks the beginning of the end.

The Foundation of Durability: Sole Construction

How the sole is attached to the upper part of the boot is the single most important factor in its long-term viability. This construction method dictates whether the boot can be repaired or must be replaced.

Goodyear Welt: The Gold Standard

A Goodyear welt is a method where a strip of leather (the "welt") is stitched to the boot's upper and a different set of stitches attaches the sole to the welt. This creates an incredibly strong, water-resistant, and—most importantly—resolable bond.

This construction is the hallmark of high-end, heritage-style boots designed to last a lifetime with proper care.

Stitched vs. Cemented (Glued) Soles

While a Goodyear welt is a specific type of stitched construction, other stitched methods also offer superior durability to cementing. A stitched sole provides a mechanical bond that is far more resilient to delamination from heat, moisture, and flexing.

In contrast, cemented construction relies on industrial adhesives to glue the sole directly to the upper. This method is faster and cheaper but often fails over time, and resoling is typically difficult or impossible.

The Power of a Replaceable Sole

The ability to replace a worn-out sole transforms a boot from a consumable item into a long-term piece of equipment. For a motorcyclist, sole wear from footpegs and pavement is inevitable. A replaceable sole means the most common failure point can be easily repaired by a cobbler.

Material Quality: The Core Components

Beyond the construction method, the materials used dictate how the boot will resist abrasion, stress, and the elements over thousands of miles.

Full-Grain Leather as the Standard

Full-grain leather is the highest quality grade, using the entire grain of the hide. It offers superior abrasion resistance, durability, and the ability to develop a unique patina over time.

Leather-lined boots also tend to outlast those with synthetic linings, as the natural material is more resilient to the constant friction and moisture inside a boot.

Strategic Reinforcements

Motorcycle boots are subjected to unique stresses. Look for reinforcements in critical areas like the ankle for impact protection, the heel and toe box for structure, and an extra layer of material on the toe for the gear shifter. These patches prevent premature wear at the points of highest contact.

Hardware That Endures

Buckles, eyelets, and zippers are potential points of failure. High-quality boots use solid brass or nickel-plated hardware that resists rust and corrosion. Flimsy or plated pot-metal hardware can break or seize, rendering an otherwise good boot useless.

Understanding the Trade-offs

Choosing a highly durable boot involves balancing longevity with other practical considerations.

Cost vs. Longevity

Boots with Goodyear welts and full-grain leather have a significantly higher upfront cost due to the skilled labor and premium materials involved. However, this initial investment often proves more economical over the long run compared to replacing cheaper, cemented boots every few years.

The Break-In Period

One of the defining characteristics of a tough, welted leather boot is a stiff initial feel. These boots require a break-in period to allow the thick leather and footbed to mold to your foot. While modern cemented boots are often comfortable out of the box, they lack this long-term custom fit.

Weight and Flexibility

Durable construction methods and robust materials inevitably add weight. A Goodyear-welted boot will almost always be heavier and less flexible than a lightweight, synthetically-lined cemented boot. This is a direct trade-off between ultimate protection and walk-around comfort.

Making the Right Choice for Your Goal

Select your boot based on a clear understanding of your primary needs and budget.

- If your primary focus is maximum longevity and repairability: Prioritize a boot with a Goodyear welt construction and full-grain leather uppers.

- If your primary focus is balancing durability with daily comfort: A boot with a direct-stitched sole (even if not a full welt) and quality leather offers a great compromise.

- If your primary focus is a tight budget: Look for the most robust materials you can afford, paying close attention to the quality of the hardware and ensuring the sole is, at a minimum, stitched rather than just glued.

Ultimately, investing in a well-constructed boot is an investment in your safety and a commitment to gear that is built to endure the ride.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Goodyear Welt Construction | Creates a resolable, water-resistant bond between sole and upper |

| Full-Grain Leather | Provides superior abrasion resistance and durability |

| Strategic Reinforcements | Protects high-wear areas like ankles, heels, and toes |

| Metal Hardware | Resists rust and corrosion for long-term functionality |

| Replaceable Sole | Transforms boots from disposable to long-term equipment |

As a leading footwear manufacturer, 3515 produces durable motorcycle boots built to withstand the toughest rides.

Our production capabilities include:

- Goodyear welt construction for maximum repairability

- Premium full-grain leather for superior abrasion resistance

- Strategic reinforcements at critical wear points

- Robust metal hardware that won't fail under stress

We specialize in manufacturing high-performance footwear for distributors, brand owners, and bulk clients who demand gear that lasts. Whether you need touring boots, adventure riding gear, or urban motorcycle footwear, we can deliver quality construction at scale.

Ready to offer your customers boots that are built to last? Contact our team today to discuss your motorcycle boot manufacturing needs.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What is the advantage of buying motorcycle boots in a physical store? Guarantee a Perfect, Safe Fit

- Why is weight an important factor for comfort in winter boots? Find the Perfect Balance for All-Day Wear

- What are the key factors to consider when selecting hunting boots? Find the Perfect Match for Your Terrain

- What are the health benefits of wearing warm winter shoes? Protect Your Feet from Frostbite and Falls

- How do adventure-bike boots differ from dirtbike boots? Versatility vs. Maximum Protection

- What types of motorcycle boots are suitable for urban commuting? Find the Perfect Balance of Safety & Style

- What role does ventilation play in motorcycle boots? Balancing Comfort and Performance

- How does improved grip from motorcycle boots benefit riders? Enhancing Control and Safety on Every Ride