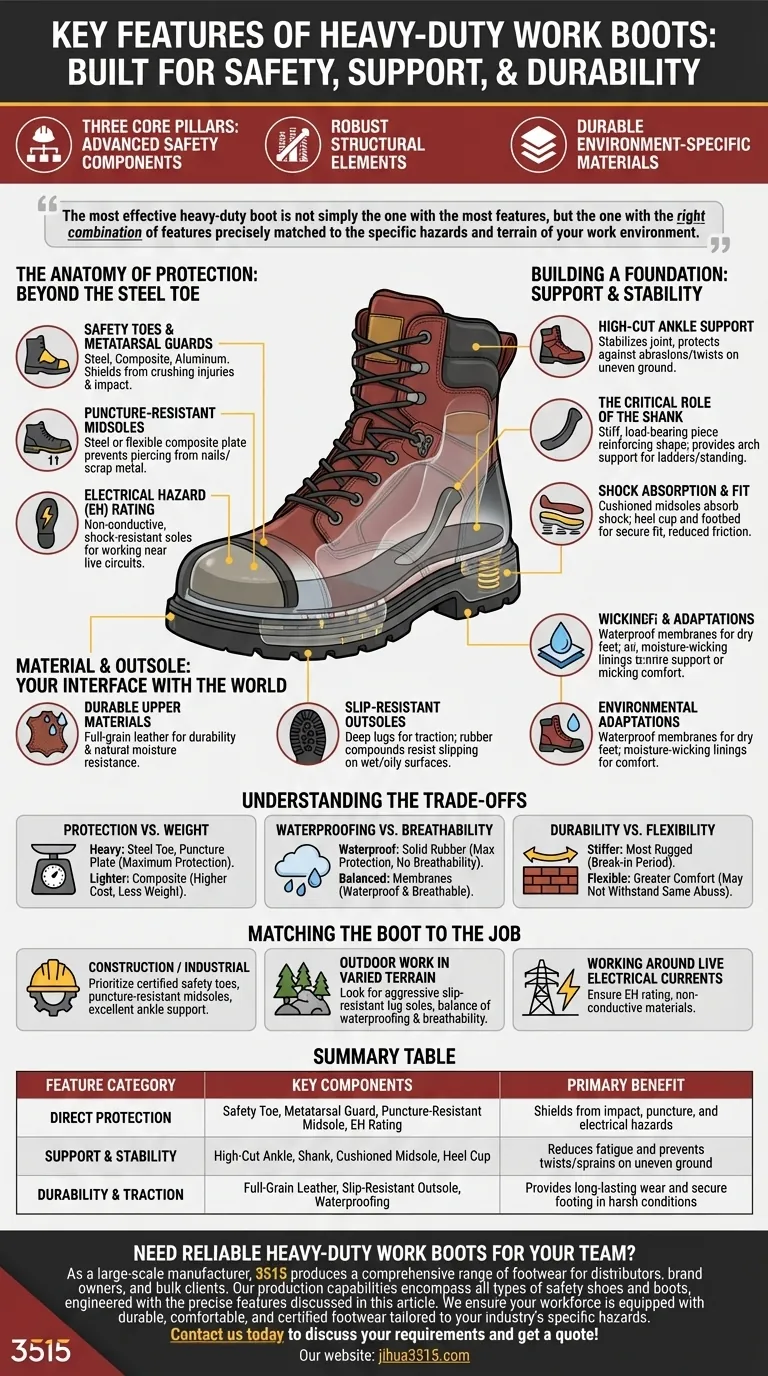

At their core, heavy-duty work boots are defined by three pillars: advanced safety components for direct protection, robust structural elements for support and stability, and durable, environment-specific materials. These features work in concert to protect you from immediate hazards like falling objects and long-term strain from demanding work conditions.

The most effective heavy-duty boot is not simply the one with the most features, but the one with the right combination of features precisely matched to the specific hazards and terrain of your work environment.

The Anatomy of Protection: Beyond the Steel Toe

The most recognizable features of work boots are those designed to shield your feet from direct impact and puncture. These are non-negotiable in many industrial and construction settings.

Safety Toes and Metatarsal Guards

A safety toe cap is the primary defense against crushing injuries from heavy, falling objects. While steel is the traditional material, modern boots also use lighter composites or aluminum.

Metatarsal guards extend this protection over the top of the foot, shielding the delicate metatarsal bones from impact.

Puncture-Resistant Midsoles

A plate, often made of steel or a flexible composite material, is embedded in the midsole. This feature is critical for preventing sharp objects like nails or scrap metal from piercing the sole of the boot and injuring your foot.

Electrical Hazard (EH) Rating

For those working near live circuits, boots with an Electrical Hazard (EH) rating are essential. They are constructed with non-conductive, shock-resistant soles and heels to provide a secondary source of protection.

Building a Foundation: Support and Stability

Heavy-duty work involves long hours on your feet, often on uneven or challenging surfaces. The boot's structure is designed to mitigate fatigue and prevent injuries like twists and sprains.

High-Cut Ankle Support

Most heavy-duty boots feature a high-cut design that extends above the ankle. This provides crucial support, stabilizing the joint to protect against abrasions and twists on unstable ground.

The Critical Role of the Shank

The shank is a stiff, load-bearing piece between the insole and outsole that reinforces the boot's shape. It provides arch support, which is especially important when climbing ladders or standing for extended periods.

Shock Absorption and Fit

A quality boot uses cushioned midsoles to absorb shock from walking on hard surfaces. A well-designed heel cup and footbed are also vital for holding the foot securely in place, reducing internal friction and improving stability.

Material and Outsole: Your Interface with the World

The materials used for the boot's upper and sole determine its durability, comfort, and performance in specific conditions.

Durable Upper Materials

Full-grain leather and similar rugged materials are common for their durability and natural moisture resistance. The quality of the upper directly contributes to the boot's lifespan and long-term value.

Slip-Resistant Outsoles

The outsole is your point of contact with the ground. Heavy-duty boots feature deep lug patterns for traction on uneven terrain and are often made from rubber compounds specifically designed to resist slipping on wet or oily surfaces.

Environmental Adaptations

Many boots incorporate waterproof membranes to keep feet dry in wet conditions. Paired with moisture-wicking linings, this system helps manage sweat and maintain comfort throughout the day.

Understanding the Trade-offs

Choosing the right boot involves balancing competing priorities. No single boot is perfect for every situation.

Protection vs. Weight

Features like steel toes and puncture-resistant plates add significant protection but also increase the boot's weight. Lighter composite materials can reduce this weight but may come at a higher cost.

Waterproofing vs. Breathability

A fully waterproof boot, like a solid rubber boot, offers maximum protection from water and mud. However, it provides zero breathability, which can lead to discomfort and sweat buildup. Boots with waterproof membranes attempt to balance these two needs.

Durability vs. Flexibility

The most rugged, durable materials are often stiffer, requiring a break-in period. More flexible boots may offer greater comfort out of the box but may not withstand the same level of abuse over time.

Matching the Boot to the Job

Use the hazards of your specific workplace as your guide.

- If your primary focus is construction or industrial sites: Prioritize boots with certified safety toes, puncture-resistant midsoles, and excellent ankle support.

- If your primary focus is outdoor work in varied terrain: Look for aggressive, slip-resistant lug soles and a balance of waterproofing and breathability.

- If your primary focus is working around live electrical currents: Ensure your boots have a clearly stated Electrical Hazard (EH) rating and are built from non-conductive materials.

Ultimately, viewing your work boots as a critical piece of specialized equipment is the key to making the right investment in your safety and comfort.

Summary Table:

| Feature Category | Key Components | Primary Benefit |

|---|---|---|

| Direct Protection | Safety Toe, Metatarsal Guard, Puncture-Resistant Midsole, EH Rating | Shields from impact, puncture, and electrical hazards |

| Support & Stability | High-Cut Ankle, Shank, Cushioned Midsole, Heel Cup | Reduces fatigue and prevents twists/sprains on uneven ground |

| Durability & Traction | Full-Grain Leather, Slip-Resistant Outsole, Waterproofing | Provides long-lasting wear and secure footing in harsh conditions |

Need Reliable Heavy-Duty Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise features discussed in this article. We ensure your workforce is equipped with durable, comfortable, and certified footwear tailored to your industry's specific hazards.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- How should one choose between steel toe and composite toe shoes? Match Your Work Hazards for Optimal Safety

- Why choose steel toe boots over composite? For Maximum Impact Protection & Durability