Ultimately, someone chooses steel toe boots for their superior impact protection, proven durability, and affordability. While composite toe boots offer modern advantages in weight and insulation, steel remains the benchmark for raw strength in hazardous environments.

The decision between steel and composite toe boots is a trade-off between maximum protection and specialized comfort. Steel offers the highest level of impact resistance, while composite provides a lighter, non-conductive alternative better suited for extreme temperatures and electrical work.

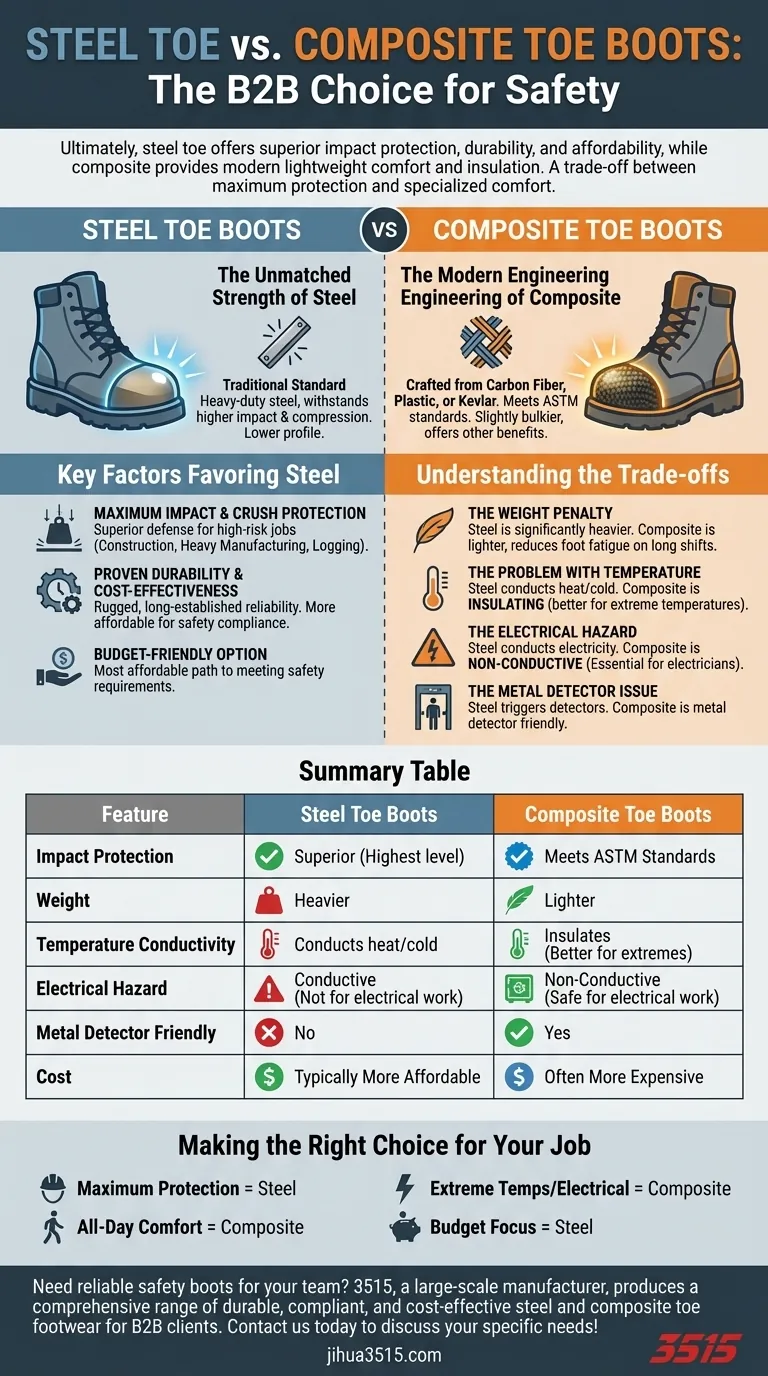

The Core Difference: How They Protect You

The fundamental distinction between these two safety boots lies in the material used for the protective toe cap. This single choice creates a cascade of differences in weight, conductivity, and performance.

The Unmatched Strength of Steel

Steel toe caps are the traditional standard for safety footwear. They are made from heavy-duty steel, which allows them to withstand higher levels of impact and compression than most composite alternatives.

This inherent strength means they can often be made with a lower profile, taking up less space in the toe box of the boot.

The Modern Engineering of Composite

Composite toe caps are crafted from non-metallic materials like carbon fiber, plastic, or Kevlar. They are engineered to meet the same official ASTM safety standards as steel toes.

However, to achieve a similar level of protection, composite caps must often be slightly bulkier. Their primary advantage is not in exceeding steel's strength, but in offering other performance benefits.

Key Factors Favoring Steel Toes

While composite technology has advanced, there are clear scenarios where steel remains the superior and more practical choice.

Maximum Impact and Crush Protection

The single greatest advantage of a steel toe is its capacity for protection. For jobs with a significant risk of heavy falling objects or compression hazards—such as in construction, heavy manufacturing, or logging—steel offers the highest possible level of defense.

Proven Durability and Cost-Effectiveness

Steel is an exceptionally durable material. Boots with steel toes are built for rugged work environments and have a long-established reputation for reliability.

Furthermore, steel toe boots are often more affordable than their composite counterparts, providing a cost-effective way to meet mandatory safety requirements.

Understanding the Trade-offs

Choosing steel comes with a clear set of disadvantages. These trade-offs are precisely why composite toe boots were developed and have become a popular alternative.

The Weight Penalty

The most noticeable drawback of steel toe boots is their weight. Steel is significantly heavier than composite materials, which can lead to greater foot fatigue over the course of a long workday.

The Problem with Temperature

Steel is an excellent thermal conductor. This means in cold environments, the steel cap will draw heat away from your feet, making them feel colder. In very hot conditions, it can retain heat. Composite materials, by contrast, are insulators and do not conduct temperature.

The Electrical Hazard

As a metal, steel conducts electricity. This makes steel toe boots entirely unsuitable and dangerous for electricians or anyone working in an environment with a risk of live electrical currents. Composite toes are non-conductive and are the required choice for these professions.

The Metal Detector Issue

For individuals who must pass through metal detectors regularly, such as airport staff or workers in secure facilities, steel toe boots can be a constant inconvenience. Composite toes will not trigger these security devices.

Making the Right Choice for Your Job

Selecting the correct safety boot is not about which type is "better," but which is better suited for your specific daily tasks and environment.

- If your primary focus is maximum protection from heavy objects: Choose steel for its superior impact and compression resistance, especially in high-risk industries.

- If your primary focus is all-day comfort and reduced fatigue: Choose composite for its lighter weight, which makes a significant difference during long shifts with extensive walking.

- If you work in extreme temperatures or with electrical hazards: Choose composite for its crucial non-conductive and insulating properties.

- If your primary focus is budget: Steel toe boots often provide the most affordable path to meeting safety compliance without sacrificing core protection.

Understanding these core trade-offs empowers you to select the safety footwear that truly serves your specific work environment.

Summary Table:

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Impact Protection | Superior (Highest level) | Meets ASTM Standards |

| Weight | Heavier | Lighter |

| Temperature Conductivity | Conducts heat/cold | Insulates (Better for extremes) |

| Electrical Hazard | Conductive (Not for electrical work) | Non-Conductive (Safe for electrical work) |

| Metal Detector Friendly | No | Yes |

| Cost | Typically More Affordable | Often More Expensive |

Need reliable safety boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and composite toe footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, compliant, and cost-effective boots for any industry. Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- Why are steel toe boots considered durable? Built to Last in the Toughest Conditions

- When should steel toe boots be replaced? Protect Your Feet from Costly Workplace Injuries

- What workplace factors should be considered when choosing between steel and safety toes? Ensure Optimal Foot Protection

- What materials are used for impact-resistant toes? Steel, Aluminum, or Composite?

- When are steel-toe boots required or recommended? Essential Guide to Workplace Foot Safety

- What are the 5 main protections offered by steel toe boots? A Guide to Workplace Foot Safety