At its core, a safety toe cap is a reinforced protective shield integrated into the toe area of footwear. It is designed to protect your feet from serious injury caused by falling objects or compression. The two primary categories of materials used for these caps are traditional steel and modern composite materials.

The choice between safety toe materials is no longer just about protection. It's a critical decision that balances the traditional strength of steel against the lightweight, non-metallic advantages of modern composites like carbon fiber, fiberglass, and Kevlar.

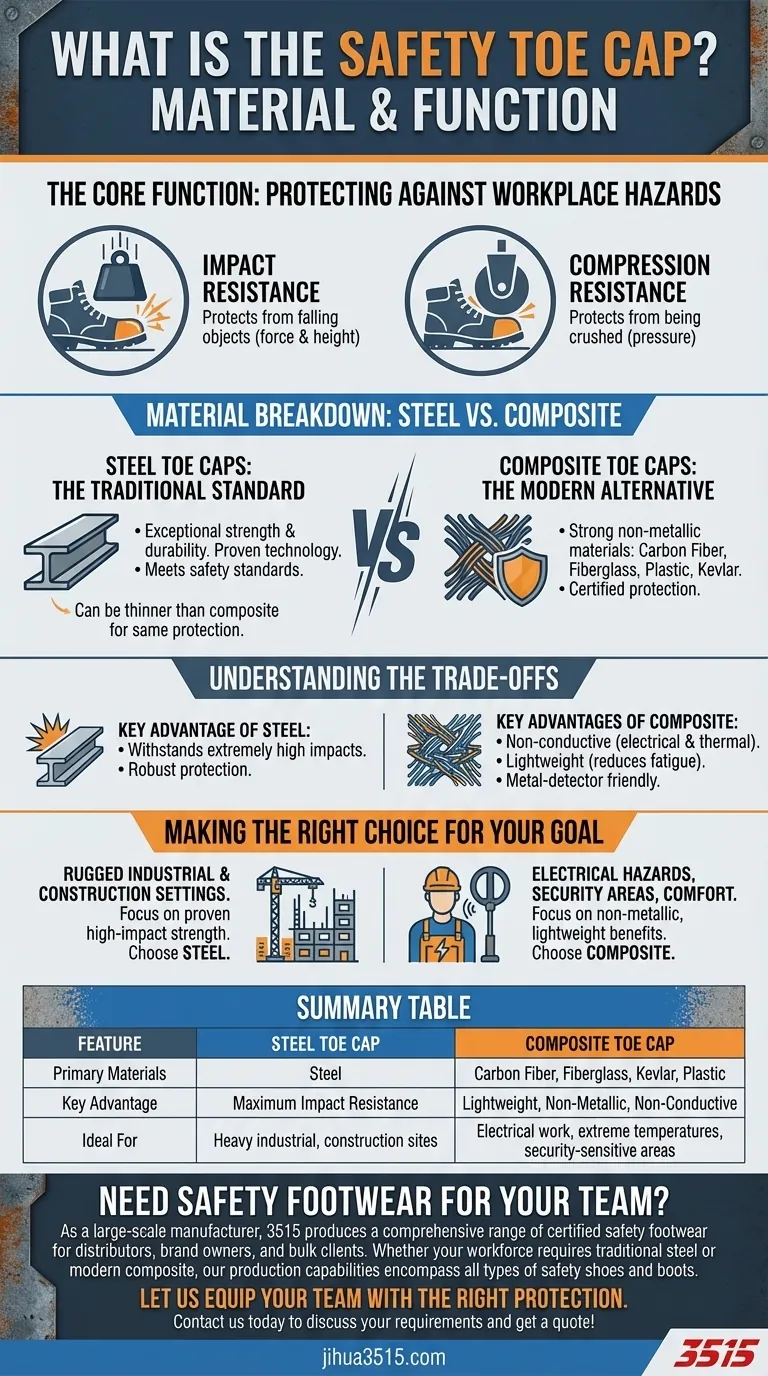

The Core Function: Protecting Against Workplace Hazards

A safety toe cap's purpose is to prevent two specific types of injuries that are common in industrial, construction, and warehouse environments.

Impact Resistance

This is the cap's ability to protect the toes from the force of a falling object. Safety standards specify the amount of weight dropped from a certain height that the cap must withstand.

Compression Resistance

This refers to the cap's ability to protect the toes from being crushed under a heavy rolling or stationary object. The cap must resist a specified amount of pressure without deforming to a point that would cause injury.

Material Breakdown: Steel vs. Composite

The material used in the toe cap is the single most important factor determining its properties, weight, and ideal use case.

Steel Toe Caps: The Traditional Standard

For decades, steel has been the default material for safety toes due to its exceptional strength and durability. It provides robust protection and is a proven technology in safety footwear.

These caps must meet specific regional safety standards, such as those set in Europe or North America, to ensure they provide a reliable level of protection.

Composite Toe Caps: The Modern Alternative

Composite toe caps are made from a range of strong, non-metallic materials. This category includes advanced materials like carbon fiber, fiberglass, plastic, or Kevlar.

The primary advantage of these materials is that they offer certified protection without the properties of metal.

Understanding the Trade-offs

Neither material is universally "better"; they simply offer different benefits for different working conditions.

Key Advantage of Steel

Steel's main advantage is its ability to withstand extremely high impacts. Because it is so strong, the cap itself can be made thinner than a composite cap while still meeting the same safety standard, sometimes resulting in a less bulky boot.

Key Advantages of Composite

Composite materials do not conduct electricity, making them ideal for electricians or workers in environments where electrical hazards are a concern. They also don't conduct heat or cold, providing better insulation in extreme temperatures.

Furthermore, being non-metallic means they won't set off metal detectors, a significant benefit for workers in security-sensitive areas. They are also generally lighter than steel, which can reduce foot fatigue over a long day.

Making the Right Choice for Your Goal

Your specific work environment and daily tasks should dictate your choice of safety toe material.

- If your primary focus is proven, high-impact strength in rugged industrial or construction settings: Steel toe caps remain the traditional and highly effective standard.

- If you work around electrical hazards, pass through metal detectors, or need a lighter boot for comfort: Composite toe caps provide the necessary protection with significant environmental and comfort advantages.

Understanding the fundamental difference between these materials empowers you to select footwear that offers not just safety, but the right kind of safety for your job.

Summary Table:

| Feature | Steel Toe Cap | Composite Toe Cap |

|---|---|---|

| Primary Materials | Steel | Carbon Fiber, Fiberglass, Kevlar, Plastic |

| Key Advantage | Maximum Impact Resistance | Lightweight, Non-Metallic, Non-Conductive |

| Ideal For | Heavy industrial, construction sites | Electrical work, extreme temperatures, security-sensitive areas |

Need Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the traditional strength of steel or the modern benefits of composite, our production capabilities encompass all types of safety shoes and boots.

Let us equip your team with the right protection. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- How do abrasion-resistant work boots extend equipment service life? Maximize Durability in Harsh Outdoor Environments