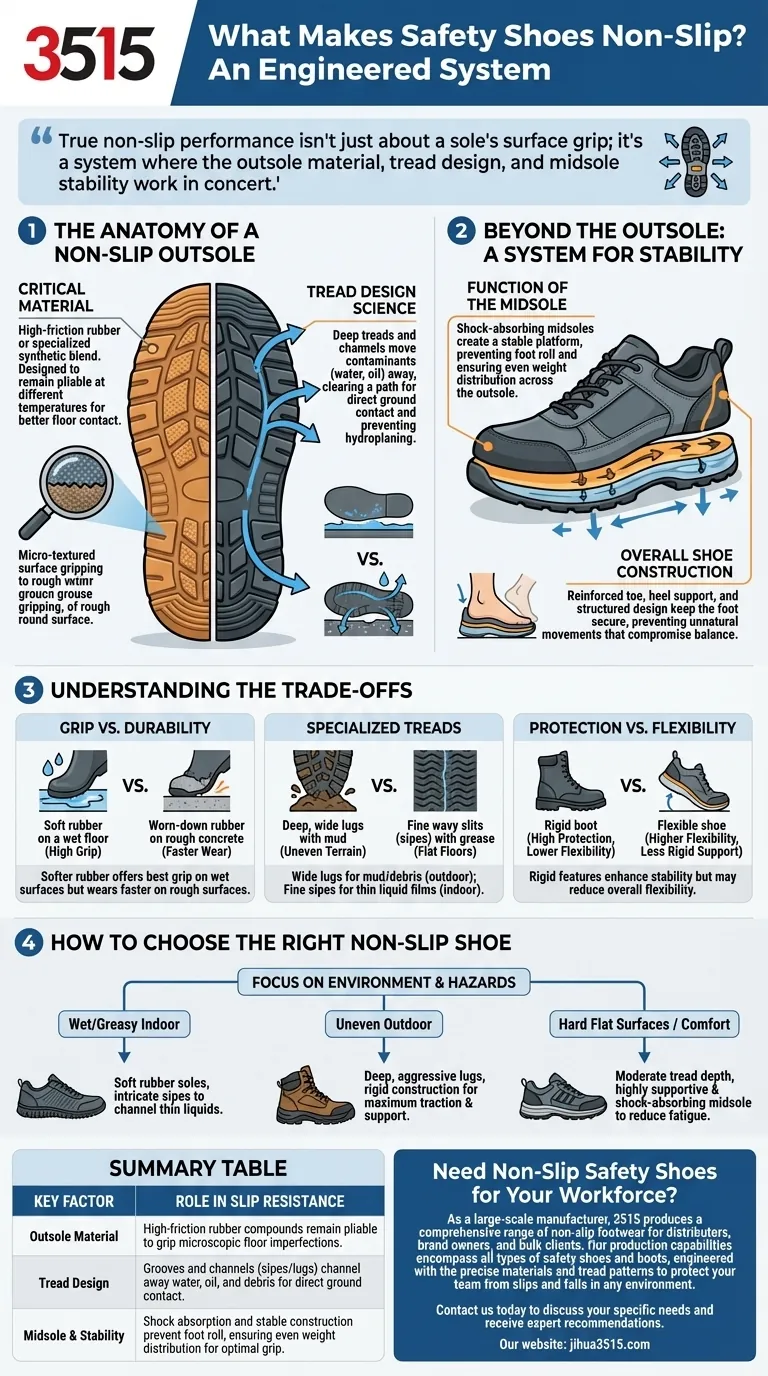

The non-slip capability of a safety shoe is not the result of a single feature, but an engineered system. It is primarily determined by the outsole's specific material composition and the physical design of its tread pattern, which work together to maximize grip on hazardous surfaces. The overall stability and support of the shoe's construction further enhance this effect.

True non-slip performance isn't just about a sole's surface grip; it's a system where the outsole material, tread design, and midsole stability work in concert to maintain firm contact and control, especially on wet or uneven ground.

The Anatomy of a Non-Slip Outsole

The part of the shoe that contacts the ground is where slip resistance is born. It's a careful balance of chemistry and physics.

The Critical Role of Material

The outsole is typically made from a high-quality rubber or a specialized synthetic compound. The specific blend is chosen for its high coefficient of friction, which is the scientific measure of "grippiness."

These materials are designed to remain pliable across different temperatures to ensure they can conform to microscopic imperfections in a floor surface, thereby increasing contact area and traction.

The Science of Tread Design

A flat, smooth sole would easily hydroplane on wet surfaces, much like a bald tire. The non-slip outsole features a rugged, intentional pattern of grooves and channels.

These deep treads are engineered to channel water, oil, and other contaminants away from the point of contact between the sole and the floor. This action clears a path for the solid parts of the tread to make direct, firm contact with the ground, drastically reducing the risk of a slip.

Beyond the Outsole: A System for Stability

While the outsole provides the direct grip, the rest of the shoe's structure is essential for making that grip effective.

The Function of the Midsole

Safety shoes often include shock-absorbing midsoles. While this provides comfort, its primary safety function is to create a stable platform for your foot.

A stable midsole prevents your foot from rolling or shifting excessively inside the shoe. This ensures your weight is distributed evenly across the outsole, allowing the treads to function as designed.

Overall Shoe Construction

The entire shoe, including features like a reinforced toe cap and a supportive heel cup, contributes to stability. By keeping your foot securely in place, the shoe prevents unnatural movements that could compromise your balance and lead to a slip, even if the outsole has excellent grip.

Understanding the Trade-offs

No single shoe is perfect for every environment. Choosing the right non-slip shoe means understanding the inherent compromises in its design.

Grip vs. Durability

Softer rubber compounds generally offer the best grip, especially on smooth, wet surfaces. However, they also tend to wear down faster, particularly on rough, abrasive surfaces like concrete or gravel.

Specialized Treads for Specific Hazards

A tread pattern with deep, wide-spaced lugs is excellent for shedding mud and debris on uneven outdoor terrain. Conversely, a pattern with many fine, wavy slits (called sipes) is superior at channeling away thin films of water or grease on a flat kitchen floor. One design is not universally better than the other.

Protection vs. Flexibility

Features that enhance stability, such as rigid shanks and reinforced construction, can sometimes reduce the shoe's overall flexibility. This can be a drawback for workers who need to frequently crouch, kneel, or pivot.

How to Choose the Right Non-Slip Shoe

Focus on the specific hazards of your environment to make an informed decision.

- If your primary focus is working on wet or greasy indoor surfaces: Seek out shoes with softer rubber soles and intricate tread patterns designed to channel away thin liquids.

- If your primary focus is navigating uneven outdoor terrain: Prioritize shoes with deep, aggressive lugs and a more rigid construction for maximum traction and ankle support.

- If your primary focus is all-day comfort on hard, flat surfaces: Consider a shoe that balances a moderate tread depth with a highly supportive, shock-absorbing midsole to reduce fatigue.

Understanding these core principles allows you to look beyond marketing claims and select a shoe truly engineered for your specific safety needs.

Summary Table:

| Key Factor | Role in Slip Resistance |

|---|---|

| Outsole Material | High-friction rubber compounds remain pliable to grip microscopic floor imperfections. |

| Tread Design | Grooves and channels (sipes/lugs) channel away water, oil, and debris for direct ground contact. |

| Midsole & Stability | Shock absorption and stable construction prevent foot roll, ensuring even weight distribution for optimal grip. |

Need Non-Slip Safety Shoes for Your Workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise materials and tread patterns to protect your team from slips and falls in any environment.

Contact us today to discuss your specific needs and receive expert recommendations.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals