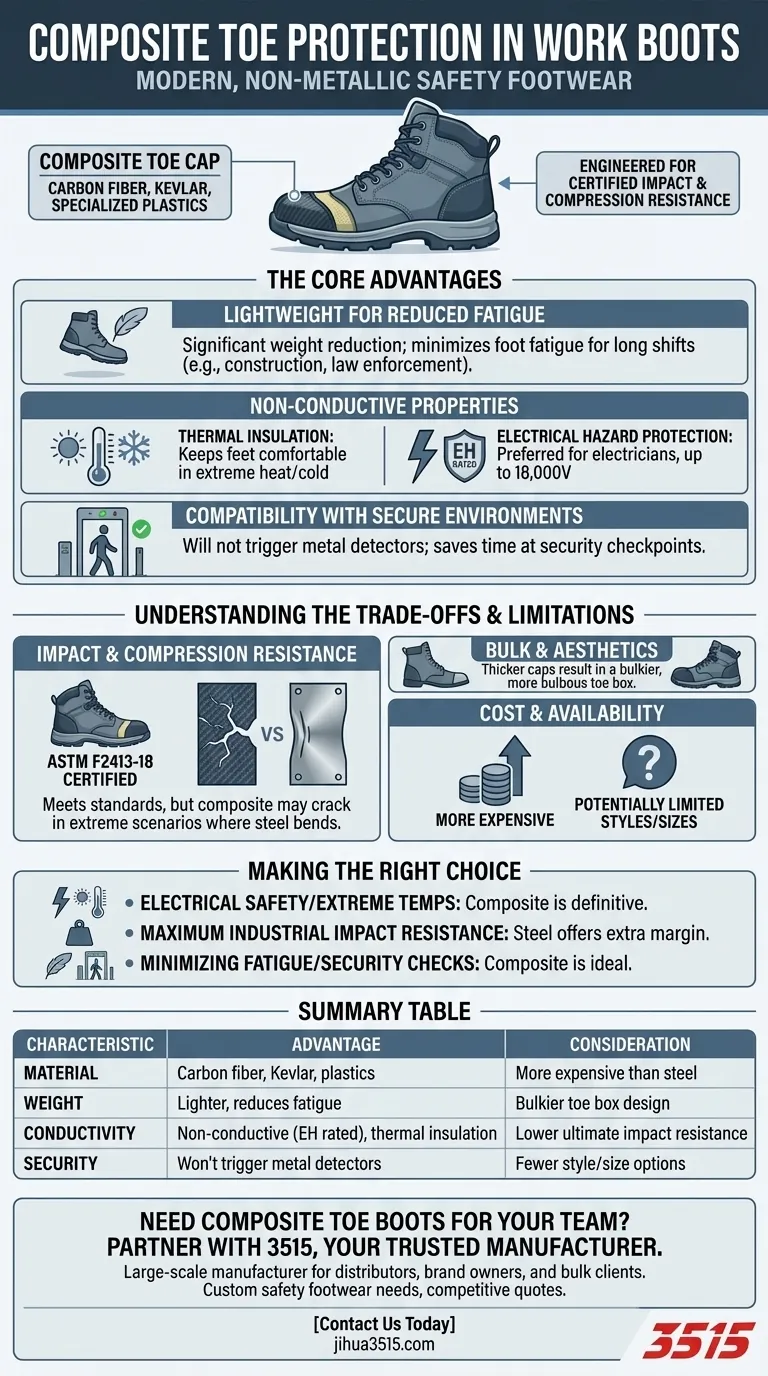

At their core, composite toe protectors are a modern, non-metallic form of safety footwear. Constructed from materials like carbon fiber, Kevlar, and specialized plastics, they are engineered to provide certified impact and compression resistance without the weight and conductivity of traditional steel toes.

The central takeaway is that composite toe protection offers a lightweight, non-conductive alternative to steel, making it superior for environments with electrical hazards, extreme temperatures, or metal detectors. However, this comes with trade-offs in cost, bulk, and potentially lower ultimate impact resistance compared to steel.

The Core Advantages of Composite Toe Protection

Composite toe boots have gained popularity because they solve specific problems that traditional steel toe boots cannot. Their advantages stem directly from their non-metallic construction.

Lightweight for Reduced Fatigue

The most noticeable characteristic is their reduced weight. By using materials like carbon fiber instead of steel, composite toe caps significantly lighten the boot.

This reduction minimizes foot fatigue over long workdays, a crucial benefit for professionals who are constantly on their feet in industries like construction or law enforcement.

Non-Conductive Properties

Being completely free of metal gives composite toes two major non-conductive advantages.

First, they provide excellent thermal insulation. They do not conduct heat or cold, keeping feet more comfortable in extreme temperature environments.

Second, they offer superior electrical hazard (EH) protection. Since the materials do not conduct electricity, they are the preferred choice for electricians and anyone working near live circuits. Some are rated to protect against circuits up to 18,000 volts in dry conditions.

Compatibility with Secure Environments

The non-metallic nature of composite toe boots makes them ideal for high-security workplaces.

They will not trigger metal detectors, saving time and hassle for employees who must pass through security checkpoints frequently.

Understanding the Trade-offs and Limitations

While composite toe technology offers clear benefits, it's essential to understand its limitations to make an informed decision. These trade-offs are critical for choosing the right protection for the job.

Impact and Compression Resistance

Reputable composite toe boots meet the same ASTM F2413-18 standards for impact and compression as their steel counterparts. They are tested and certified to protect you from common workplace hazards.

However, in an extreme impact scenario that exceeds the ASTM standard, steel and composite materials fail differently. Steel tends to bend, while a composite material may crack. For this reason, some professionals in the heaviest industrial settings still prefer the known performance of steel.

Bulk and Aesthetics

To achieve the required level of protection, composite toe caps must be thicker and more voluminous than steel caps.

This results in a bulkier, more bulbous toe box on the boot, which can be a deciding factor for those concerned with the boot's profile or appearance.

Cost and Availability

Advanced materials and manufacturing processes make composite toe boots more expensive than most steel toe options.

While becoming more common, they may not be available in as wide a variety of styles or sizes as the more established steel toe models.

Making the Right Choice for Your Job

Selecting the correct safety toe is not about which is "better" overall, but which is better for your specific environment and daily tasks.

- If your primary focus is electrical safety or comfort in extreme temperatures: Composite toe is the definitive choice due to its non-conductive properties.

- If your primary focus is maximum impact resistance for heavy industrial work: Steel toe may provide an extra margin of safety in events that exceed standard testing limits.

- If your primary focus is minimizing daily fatigue and you walk through metal detectors: Composite toe's lightweight and non-metallic design is the ideal solution.

Ultimately, understanding these characteristics empowers you to choose the personal protective equipment that best serves your safety and comfort.

Summary Table:

| Characteristic | Advantage | Consideration |

|---|---|---|

| Material | Carbon fiber, Kevlar, plastics | More expensive than steel |

| Weight | Lighter, reduces fatigue | Bulkier toe box design |

| Conductivity | Non-conductive (EH rated), thermal insulation | Lower ultimate impact resistance than steel in extreme scenarios |

| Security | Won't trigger metal detectors | Fewer style/size options |

Need Composite Toe Boots for Your Team? Partner with 3515, Your Trusted Manufacturer.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe boots, ensuring your workforce gets the perfect blend of lightweight comfort, certified protection, and job-specific performance.

Contact us today to discuss your custom safety footwear needs and get a competitive quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Why is the synchronization of craftsmanship and UX development emphasized for bulk customization of safety shoes?

- What are the benefits of using EVA in safety boots? Enhance Comfort and Reduce Fatigue

- Why are high-performance ARM embedded modules used in safety systems? Ensure Real-Time Decisions & Local AI Power

- When must employers pay for OSHA-approved safety shoes? Understand Your Legal Obligations

- Why is an industrial-grade buffing machine essential for safety shoe sole-bonding? Achieve Superior Bonding Integrity

- Why are Force Sensing Resistor (FSR) sensors core for Safety Shoes? Ensure Workplace Compliance with Smart Tech

- Why is it important for the heel of a safety toe boot to fit snugly? The Key to Stability and Injury Prevention

- What materials are composite toes made from? Kevlar, Carbon Fiber & More Explained