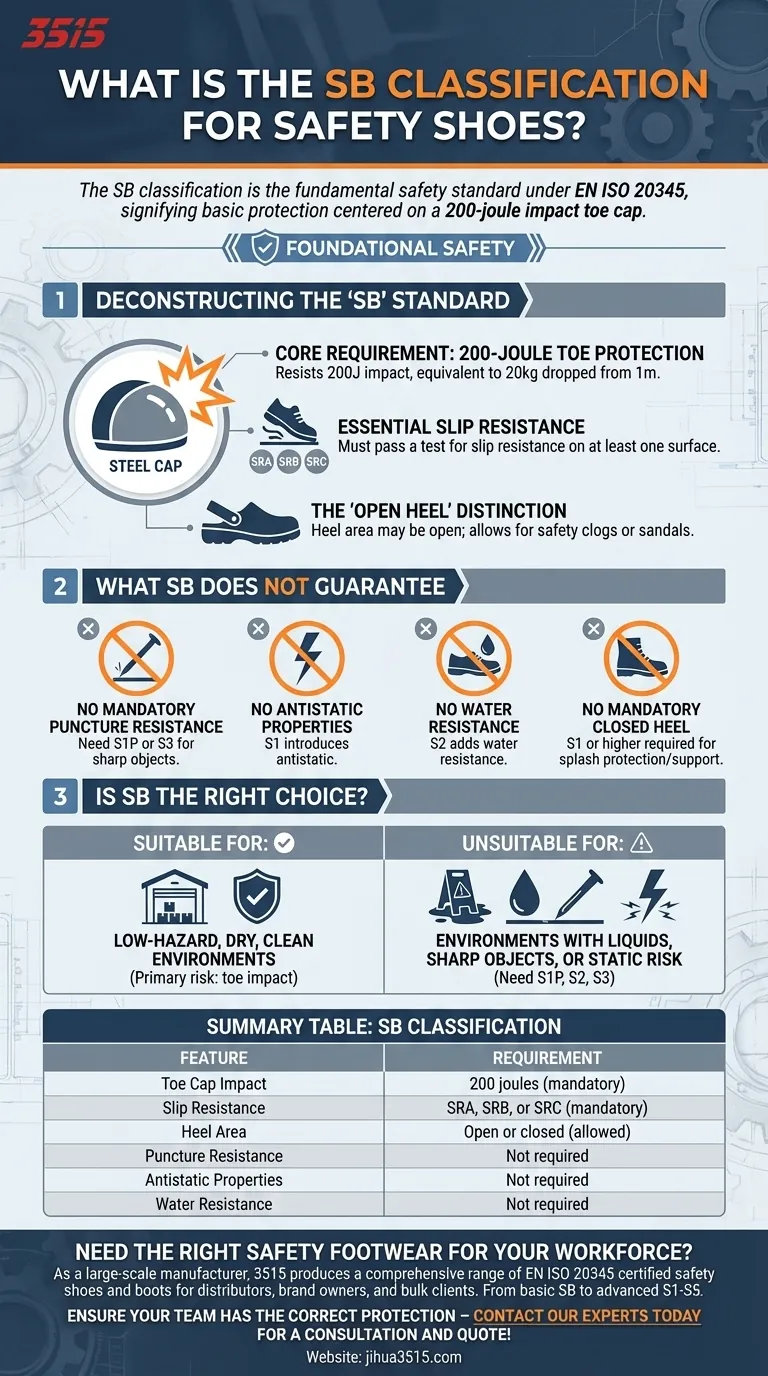

The SB classification represents the fundamental safety standard for footwear under the European EN ISO 20345 standard. It signifies that the shoe or boot meets the most basic requirements for protection, centered around a toe cap capable of withstanding a 200-joule impact.

The SB rating is the foundational building block for safety footwear. It guarantees essential toe protection and minimum slip resistance but intentionally omits the advanced features found in higher classifications like S1, S2, or S3.

Deconstructing the 'SB' Standard

Understanding the "SB" or "Safety Basic" classification is about recognizing what is required and, just as importantly, what is not. It establishes the minimum threshold a shoe must pass to be legally considered "safety footwear."

The Core Requirement: 200-Joule Toe Protection

The absolute, non-negotiable feature of any SB-rated footwear is a protective toe cap.

This cap is tested to resist an impact energy of 200 joules. This is equivalent to a 20kg (44 lb) weight being dropped onto the toes from a height of approximately one meter.

Essential Slip Resistance

All footwear certified under the EN ISO 20345 standard, including SB, must also pass a test for slip resistance on at least one type of surface.

You will see this marked as SRA (tested on ceramic tile with soap solution), SRB (tested on steel with glycerol), or SRC (tested and passed on both surfaces).

The "Open Heel" Distinction

A defining characteristic of the SB classification is that the heel area may be open. This is a key difference from S1-S5 ratings, which all require a closed heel region.

This means that footwear like safety clogs or sandals can achieve an SB rating as long as they have the required protective toe cap.

What SB Does NOT Guarantee

The "basic" nature of the SB rating means it lacks many protections that are mandatory in higher classifications. It is critical to understand these omissions before selecting SB footwear for a specific job.

No Mandatory Puncture Resistance

The SB standard does not require a puncture-resistant midsole. If you work in an environment with nails, screws, or other sharp objects on the ground, you need a rating like S1P or S3.

No Antistatic Properties

Protection against the buildup of static electricity is not a requirement for SB footwear. This feature is introduced at the S1 classification level.

No Water Resistance

SB-rated shoes are not required to have any resistance to water penetration or absorption. This protection begins with the S2 classification.

No Mandatory Closed Heel

As mentioned, SB footwear can be open-backed. If you need protection from splashes or require greater ankle support, you must choose a rating of S1 or higher.

Is SB the Right Choice for Your Workplace?

Choosing the correct safety footwear is a critical risk assessment decision. The SB rating is appropriate for specific, low-hazard environments but is insufficient for many common industrial settings.

- If your primary risk is impact to the toes in a dry, clean environment: SB-rated footwear can provide the necessary basic protection, often with enhanced comfort and breathability.

- If you work in an environment with liquids, sharp objects, or static risk: You must look beyond SB to higher classifications like S1P, S2, or S3 to ensure adequate protection against your specific hazards.

Ultimately, you must always match the footwear's safety rating directly to the known risks of your work environment.

Summary Table:

| Feature | SB Classification Requirement |

|---|---|

| Toe Cap Impact | 200 joules (mandatory) |

| Slip Resistance | SRA, SRB, or SRC (mandatory) |

| Heel Area | Open or closed (allowed) |

| Puncture Resistance | Not required |

| Antistatic Properties | Not required |

| Water Resistance | Not required |

Need the right safety footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified safety shoes and boots for distributors, brand owners, and bulk clients. Whether you require basic SB-rated models or advanced S1-S5 classifications with features like puncture resistance and waterproofing, we have the production capabilities and expertise to meet your exact needs.

Ensure your team has the correct protection — contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security