Properly maintaining your safety shoes is a critical, non-negotiable safety practice, not just a matter of appearance. The core principles involve regular inspection for damage, consistent cleaning according to manufacturer guidelines, and proper storage to preserve the materials. This routine ensures the shoe's protective features remain fully functional and significantly extends its service life.

Beyond simple cleaning, a structured maintenance routine is an essential part of your personal protective equipment (PPE) strategy. It directly impacts not only the longevity of your investment but, more importantly, your personal safety on the job.

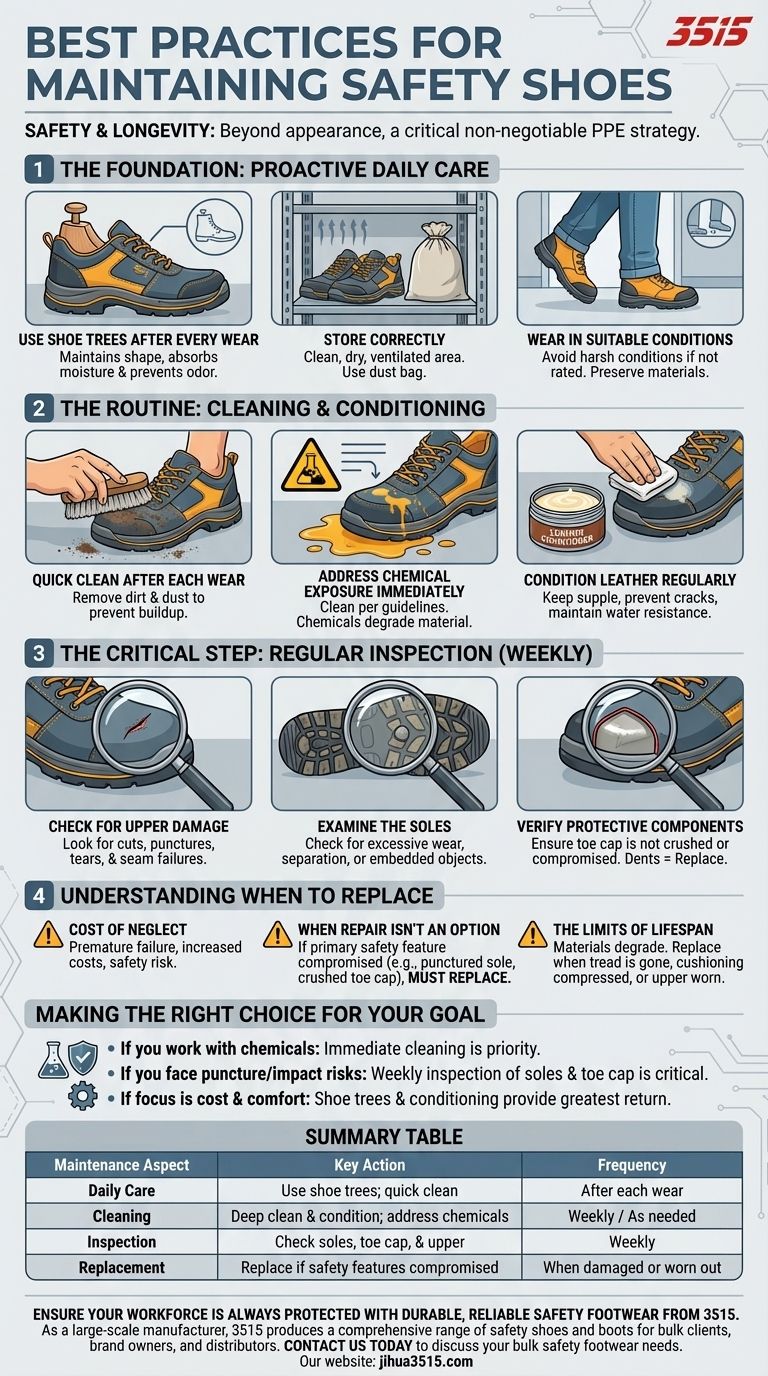

The Foundation: Proactive Daily Care

The best maintenance is preventative. Small habits performed daily have the most significant impact on the lifespan and performance of your footwear.

Use Shoe Trees After Every Wear

Shoe trees are essential for high-quality footwear, including safety shoes. They help maintain the original shape and, more importantly, absorb moisture and sweat from the lining, which prevents material breakdown and odor.

Store Them Correctly

At the end of the day, store your shoes in a clean, dry, and well-ventilated area. Using a dust bag can prevent abrasive particles from settling on the material, especially for leather.

Wear Shoes in Suitable Conditions

While many safety shoes are built to be robust, avoid unnecessary exposure to harsh conditions like heavy rain or snow if the shoe isn't specifically rated for it. This helps preserve materials like leather and waterproof liners.

The Routine: Cleaning and Conditioning

Dirt, chemicals, and moisture are the primary enemies of safety footwear. A consistent cleaning regimen is crucial for preserving their integrity.

Perform a Quick Clean After Each Wear

Use a brush or damp cloth to remove dirt and dust at the end of each shift. This prevents buildup that can abrade the shoe's upper and degrade stitching over time.

Address Chemical Exposure Immediately

If your shoes are exposed to corrosive or poisonous materials, they must be cleaned immediately according to the manufacturer's specific guidelines. Chemicals can rapidly degrade protective materials and compromise safety.

Condition Leather Regularly

For leather safety shoes, periodic polishing or conditioning is vital. This keeps the leather supple, prevents it from drying out and cracking, and maintains its natural water resistance.

The Critical Step: Regular Inspection

A visual and physical inspection is your first line of defense in identifying when a shoe is no longer safe to wear. This should be a weekly habit.

Check for Obvious Upper Damage

Look for any cuts, punctures, or tears in the shoe's main body. Pay close attention to the seams and stitching, as failures here can compromise the shoe's structural integrity.

Examine the Soles

Inspect the soles for signs of excessive or uneven wear, which can diminish anti-slip properties. Check for separation from the upper and look for any sharp objects that may have become embedded.

Verify Protective Components

Ensure the composite or steel toe cap has not been compromised, crushed, or exposed. Any significant impact that causes a dent means the shoe's protective rating is void and it must be replaced.

Understanding When to Replace

Maintenance extends life, but it cannot make a shoe last forever. Knowing when to replace your footwear is as important as knowing how to care for it.

The Cost of Neglect

Failing to maintain your shoes will lead to premature failure. This not only increases costs due to more frequent replacements but also creates a significant safety risk.

When Repair Isn't an Option

Superficial damage can sometimes be repaired, but if a primary safety feature is compromised, the shoe must be replaced. This includes a punctured sole, a crushed toe cap, or material that has been degraded by chemicals.

The Limits of Lifespan

Even with perfect care, materials degrade over time and with use. There is no set expiration date, but once the tread is gone, the cushioning is compressed, or the upper is significantly worn, it's time for a new pair.

Making the Right Choice for Your Goal

Your maintenance priority should reflect the specific hazards of your work environment.

- If you work with chemicals or corrosives: Immediate cleaning after any splash is your top priority to prevent material degradation.

- If you face puncture or impact risks: Your weekly inspection of the soles and toe cap is the most critical part of your routine.

- If your primary focus is cost-effectiveness and comfort: Using shoe trees and regular conditioning will provide the greatest return by extending the shoe's life and fit.

A consistent maintenance strategy transforms your safety shoes from a disposable item into a reliable, long-term piece of protective equipment.

Summary Table:

| Maintenance Aspect | Key Action | Frequency |

|---|---|---|

| Daily Care | Use shoe trees; quick clean with brush/cloth | After each wear |

| Cleaning | Deep clean & condition leather; address chemicals | Weekly / As needed |

| Inspection | Check soles, toe cap, and upper for damage | Weekly |

| Replacement | Replace if safety features are compromised | When damaged or worn out |

Ensure your workforce is always protected with durable, reliable safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed for longevity and performance in demanding environments.

Contact us today to discuss your bulk safety footwear needs and benefit from our expertise in durable manufacturing.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- Are there any limitations to oil resistant safety boots? Key Risks and How to Mitigate Them

- How can the mechanical design of professional footwear alleviate falls? Engineering Stability and Balance Support

- What role do industrial safety shoes play in improving the labor environment? Boost Safety and Reduce Worker Stress

- What are the benefits of proper safety footwear beyond physical protection? Boost Productivity & Morale

- What are the footwear and apparel requirements for high-risk ergonomic tasks? Gear Up for Safety and Productivity

- What safety standards do composite toe boots comply with? A Guide to ASTM, EN ISO & More

- Why is a server equipped with a high-performance GPU necessary for safety shoe violation detection systems? Ensure Real-time Accuracy & Safety

- What is the primary function of an IMU in construction safety footwear? Enhancing Real-Time Worker Protection