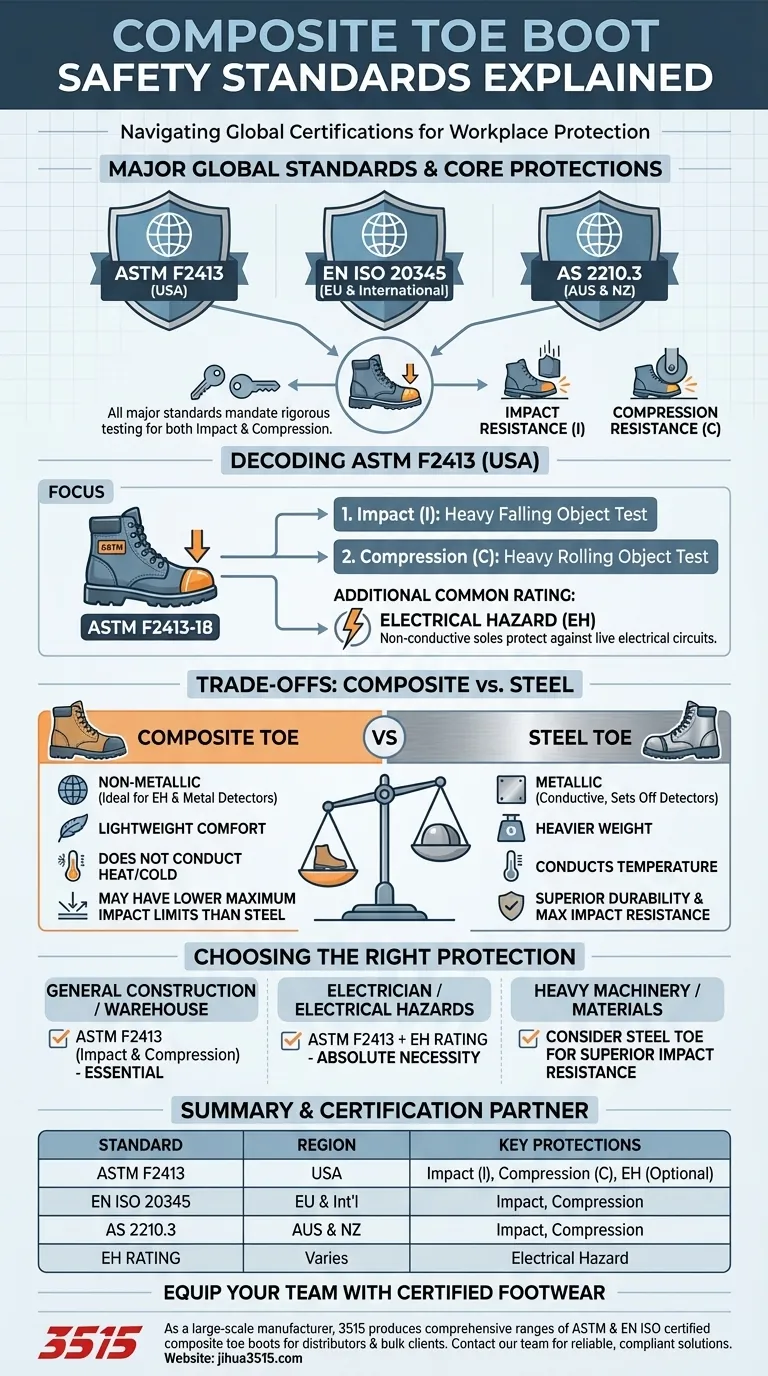

At a minimum, composite toe boots sold in major global markets must comply with specific national and international safety standards. These primary certifications include ASTM F2413 in the United States, EN ISO 20345 for Europe and international markets, and AS 2210.3 for Australia and New Zealand.

The specific standard a composite toe boot complies with is more than a label; it is a guarantee of tested performance. Understanding what these codes signify is the critical step in ensuring your footwear provides the correct type of protection for your unique workplace hazards.

Decoding the Core Safety Requirements

Safety standards are not just a general stamp of approval. They certify that a boot has passed specific, measurable tests for resisting common workplace dangers. This compliance is mandated by organizations like the Occupational Safety and Health Administration (OSHA) to ensure worker safety.

The American Standard: ASTM F2413

The most common certification in the United States is ASTM F2413. This standard establishes the minimum performance requirements for protective footwear.

At its core, ASTM F2413 tests for two critical threats:

- Impact Resistance (I): This rating measures the toe cap's ability to protect your foot from a heavy falling object.

- Compression Resistance (C): This rating measures the toe cap's ability to protect your foot from a heavy rolling object.

A boot compliant with the latest standard, often noted as ASTM F2413-18, has passed these essential tests.

The International Standard: EN ISO 20345

For boots sold in Europe and many other parts of the world, the EN ISO 20345 standard is the key certification.

Like its American counterpart, this standard also mandates rigorous testing for toe cap protection against both impact and compression, ensuring a global baseline for safety footwear performance.

Beyond the Toe Cap: Additional Protections

True workplace safety goes beyond just impact protection. The ASTM standard includes codes for various other protective features that a composite boot may offer.

The most common additional rating is for Electrical Hazard (EH). An EH-rated boot is constructed with non-conductive, shock-resistant soles and heels, providing a secondary layer of protection against accidental contact with live electrical circuits.

Other standards may cover resistance to punctures, corrosive materials, and slipping, ensuring the boot is suitable for a wide range of hazardous environments.

Understanding the Practical Trade-offs

While composite toe boots meet rigorous standards, it's crucial to understand their specific performance characteristics, especially when compared to traditional steel toe boots.

Impact Resistance Levels

While certified to protect against significant impacts, some composite materials may not offer the same absolute level of impact resistance as steel. For environments with a high risk of extremely heavy falling objects, steel may provide a higher margin of safety.

Long-Term Durability

The materials in a composite toe cap can wear down or degrade differently than steel over the boot's lifespan. Steel toe caps are exceptionally durable and less prone to losing their protective qualities over time.

The Non-Metallic Advantage

The primary benefit of composite materials is that they are non-metallic. This makes them ideal for EH-rated footwear and for workers who must pass through metal detectors. They also do not conduct heat or cold, which can be a significant comfort factor in extreme temperatures.

Making the Right Choice for Your Goal

Selecting the right boot requires matching the certified protections to your daily tasks.

- If your primary focus is general construction or warehouse work: Ensure your boot is certified to at least ASTM F2413 for impact and compression resistance.

- If your primary focus is work as an electrician or around potential electrical hazards: A certified Electrical Hazard (EH) rating is an absolute necessity in addition to the standard toe protection.

- If your primary focus is environments with exceptionally heavy machinery or materials: Carefully consider whether the superior impact resistance of a certified steel toe boot is the more appropriate choice for your specific risks.

Ultimately, understanding these standards empowers you to choose footwear based on certified, proven protection for the realities of your job.

Summary Table:

| Standard | Region | Key Protections |

|---|---|---|

| ASTM F2413 | United States | Impact (I) & Compression (C) Resistance |

| EN ISO 20345 | Europe & International | Impact & Compression Resistance |

| AS 2210.3 | Australia & New Zealand | Impact & Compression Resistance |

| EH Rating | Varies | Electrical Hazard Protection |

Ensure Your Team is Equipped with Certified Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and EN ISO certified composite toe boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you receive reliable, compliant footwear tailored to your specific workplace hazards.

Let us help you meet your safety standards. Contact our team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?