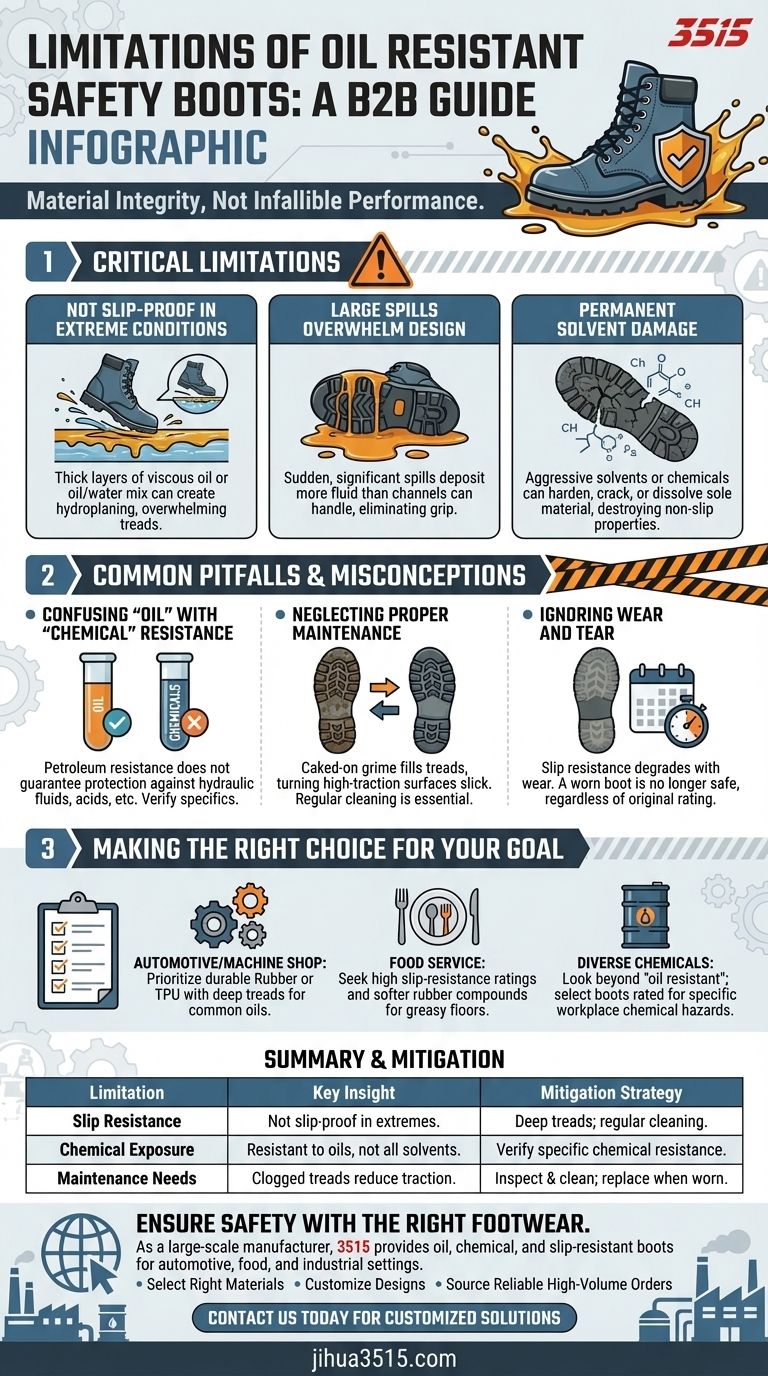

Yes, oil-resistant safety boots have critical limitations. While they are designed to prevent the boot's material from degrading when exposed to oil, this does not make them infallible. Their primary limitations are that they are not completely slip-proof in extreme conditions, their effectiveness can be compromised by large spills, and the sole material can be permanently damaged by certain solvents or chemicals.

The term "oil resistant" refers to the durability of the boot's materials against oil-induced degradation. It does not guarantee absolute slip prevention or invulnerability to all workplace hazards.

What "Oil Resistant" Actually Means

To understand the limitations, we first need to be precise about the term's meaning. It's a statement about material integrity, not just performance.

A Focus on Material Durability

The core purpose of oil-resistant construction is to ensure the boot's sole, upper, and other components do not weaken, swell, or fall apart after repeated contact with oil. This is crucial for the boot's longevity and structural safety.

The Role of Specialized Materials

These boots utilize specialized compounds like oil-resistant elastomers, rubber, and thermo-polyurethane (TPU). These materials are engineered to maintain their physical properties, especially when exposed to the elevated temperatures often found in industrial environments.

The Key Limitations You Must Consider

An oil-resistant rating is a critical safety feature, but it is not a shield against all risks. Understanding where this protection ends is essential for staying safe.

Slip Resistance Is Not Slip-Proof

Even a boot with a superior non-slip sole can lose traction in extreme conditions. A thick layer of viscous oil or a combination of oil and water can create a hydroplaning effect, overwhelming the sole's tread pattern and leading to a fall.

Large Spills Can Overwhelm the Design

The tread on a slip-resistant sole is designed to channel liquids away from the point of contact. However, a large or sudden spill can deposit more fluid than the channels can handle, effectively eliminating the sole's grip on the floor surface.

Permanent Damage from Solvents is Possible

While resistant to common oils, the boot's sole may not be resistant to more aggressive industrial solvents or chemicals. Certain chemicals can permanently harden, crack, or dissolve the sole material, destroying its non-slip properties.

Common Pitfalls and Misconceptions

Relying on the "oil resistant" label without understanding its context can lead to a false sense of security.

Confusing "Oil Resistant" with "Chemical Resistant"

This is the most critical distinction. A boot certified for resistance to petroleum-based oils may offer little to no protection against hydraulic fluids, brake cleaners, acids, or other chemicals. Always verify resistance for the specific substances in your work environment.

Neglecting Proper Maintenance

For a non-slip sole to work, its treads must be clean. Caked-on grime, dirt, and old oil can fill the channels in the outsole, turning a high-traction surface into a smooth, slick one. Regular cleaning is essential for maintaining performance.

Ignoring Wear and Tear

The slip-resistant properties of a boot sole degrade over time. As the tread wears down, its ability to grip and channel fluids diminishes. A worn-out oil-resistant boot is no longer a safe boot, regardless of its original specifications.

Making the Right Choice for Your Goal

Select your footwear based on a clear-eyed assessment of your specific workplace hazards, not just a single feature.

- If your primary focus is a general automotive or machine shop: Prioritize boots with a durable rubber or TPU sole that has a deep, well-defined tread pattern for channeling away common oils and lubricants.

- If your primary focus is a food service or processing environment: Look for boots with a high slip-resistance rating, often made from softer rubber compounds that offer superior grip on wet and greasy tile floors.

- If your primary focus is an environment with diverse chemicals: You must move beyond a simple "oil resistant" label and seek boots rated for the specific chemical hazards you face.

Understanding these limitations is the first step toward selecting footwear that provides genuine protection for the realities of your job.

Summary Table:

| Limitation | Key Insight | Mitigation Strategy |

|---|---|---|

| Slip Resistance | Not slip-proof in extreme conditions (e.g., thick oil/water mix). | Choose boots with deep treads; clean soles regularly. |

| Chemical Exposure | Resistant to oils, but not all solvents; soles can crack or harden. | Verify chemical resistance for your specific workplace hazards. |

| Maintenance Needs | Treads clogged with grime reduce traction; wear degrades performance. | Inspect and clean boots frequently; replace when worn. |

Ensure your team's safety with the right footwear for your specific environment.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots for distributors, brand owners, and bulk clients. Our production capabilities include oil-resistant, chemical-resistant, and slip-resistant footwear designed for automotive, food processing, and industrial settings.

We help you:

- Select the right materials (e.g., oil-resistant rubber, TPU) for your workplace hazards.

- Customize designs for optimal traction, durability, and comfort.

- Source reliable, high-volume orders with consistent quality.

Contact us today to discuss your safety footwear needs and get a customized solution: Get in Touch

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the primary protective functions of industrial-grade safety shoes in underground mining? Secure Your Workers.

- What replaced the ANSI Z41 standard? A Guide to Modern ASTM F2413 Safety Footwear

- Why is the use of high-barrier materials essential in Safety Shoes? Protect Feet in Hazardous Industrial Environments

- When is chainsaw protection (CS) required in safety footwear? Essential for Ground-Level Chainsaw Operation

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- Why must differences between Russian GOST 11373 and European safety shoe standards be considered? Ensure Precision Fit.

- In what ways does sensor integration technology enhance safety shoes? Revolutionize Worker Protection with Active Data

- How is the sole attached to the upper in safety shoes manufacturing? Choose the Right Bond for Durability