To properly clean and maintain oil-resistant safety boots, you must adopt a routine of consistent care. After each use, remove loose mud and debris with a stiff brush. For a deeper clean, use a mild solution of soap and water or vinegar and water, then allow the boots to air dry away from direct heat, stuffing them with newspaper if they are soaked.

The key to maximizing the life and protective qualities of your oil-resistant boots is not occasional deep cleaning, but rather a consistent maintenance routine that prevents the buildup of damaging substances and preserves the integrity of the boot's materials.

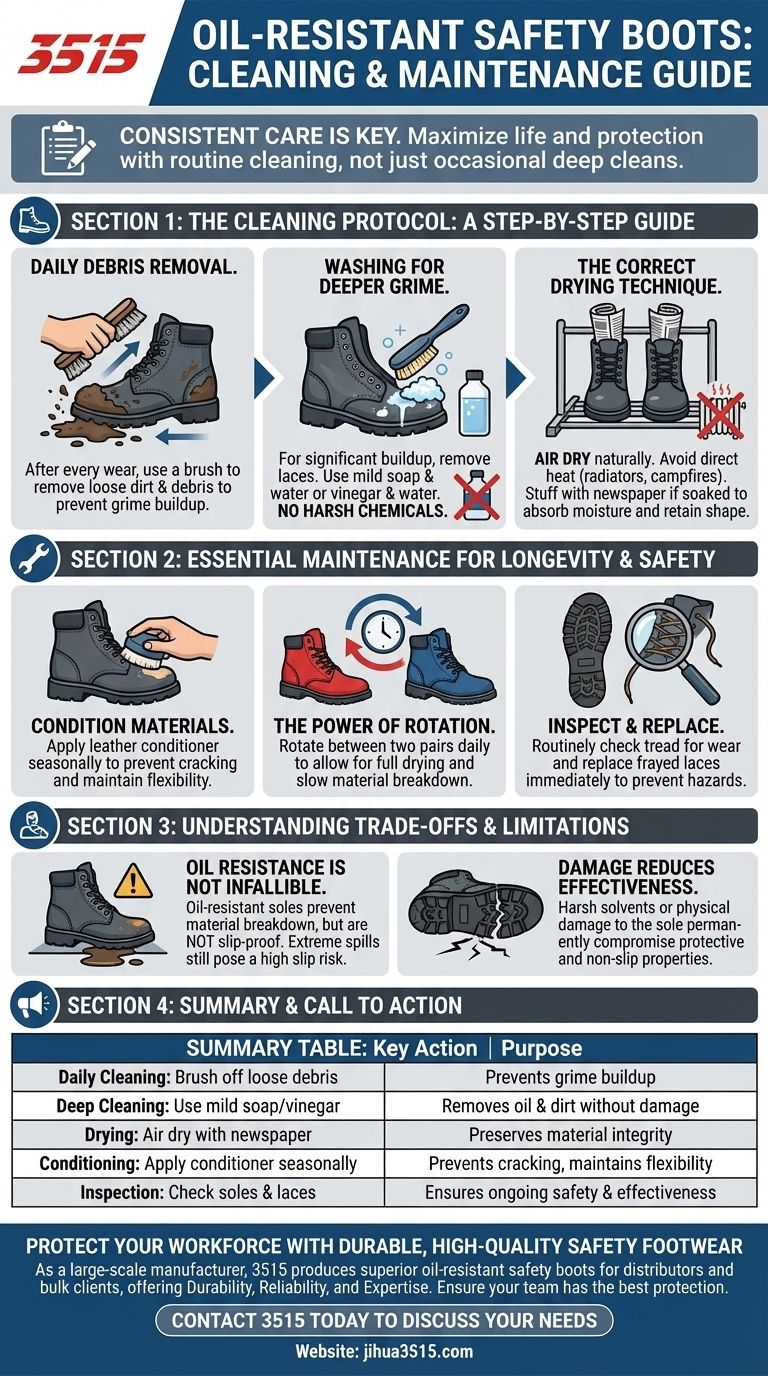

The Cleaning Protocol: A Step-by-Step Guide

Proper cleaning is the foundation of boot maintenance. It removes abrasive dirt and corrosive oils that can degrade the boot's sole and upper materials over time.

Step 1: Immediate Debris Removal

After every single wear, use a boot brush to remove loose dirt, mud, and other debris.

This simple, daily habit prevents grime from setting into the seams and material, making deeper cleans much more effective and less frequent.

Step 2: Washing for Deeper Grime

For more significant buildup, remove the laces to access all parts of the boot.

Use a soft brush or cloth with a mild solution of soap and warm water to gently scrub away dirt. A mix of water and vinegar is also an effective and gentle option.

Avoid harsh chemicals and solvents at all costs. These can permanently damage the boot's material and compromise the oil-resistant and non-slip properties of the sole.

Step 3: The Correct Drying Technique

Never use a direct heat source like a radiator or campfire to dry your boots, as excessive heat can crack leather and damage adhesives.

Allow them to air dry naturally in a well-ventilated area.

If your boots are completely soaked, stuff them tightly with newspaper. The paper will absorb the excess moisture and help the boots retain their shape as they dry.

Essential Maintenance for Longevity and Safety

Beyond cleaning, proactive maintenance is critical for ensuring your boots provide reliable protection for their entire lifespan.

Conditioning the Materials

The materials in your boots, especially leather, need moisture to remain flexible and durable.

Apply a quality leather conditioner or oil-based treatment seasonally. This replenishes the natural oils, prevents cracking, and can refresh the boot's water resistance.

The Power of Rotation

If possible, own two pairs of safety boots and rotate them daily.

This gives each pair a full 24 hours to dry out completely, which dramatically slows the breakdown of materials and the growth of bacteria, extending the life of both pairs.

Inspect and Replace Components

Routinely check for wear and tear. Pay close attention to the soles, ensuring the tread is not worn down, which would reduce its slip-resistant effectiveness.

Frayed or worn laces should be replaced immediately, as a broken lace can create a significant safety hazard on the job.

Understanding the Trade-offs and Limitations

Even the highest quality boots have limitations. Understanding them is key to staying safe and managing expectations for their durability.

Oil Resistance is Not Infallible

Oil-resistant soles are designed to prevent the material from breaking down when exposed to petroleum products. This is not the same as being "slip-proof."

In conditions of extreme oil or chemical spills, the risk of slipping can still be high. These boots reduce the risk, they do not eliminate it.

Damage Can Reduce Effectiveness

The boot's protective features can be permanently compromised.

Harsh solvents or significant physical damage to the sole can degrade its non-slip surface, reducing its effectiveness even if the rest of the boot appears fine.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your primary needs and work environment.

- If your primary focus is daily safety: Make it a non-negotiable habit to brush off your boots and inspect the soles for wear after every shift.

- If your primary focus is maximizing lifespan: The most impactful actions are rotating your boots daily and applying a quality conditioner every few months.

- If your primary focus is recovering from heavy exposure: Follow the deep clean protocol with a mild soap solution and use the newspaper method to dry them thoroughly.

Consistent, mindful care is the most effective way to protect your investment and ensure your boots continue to protect you.

Summary Table:

| Maintenance Step | Key Action | Purpose |

|---|---|---|

| Daily Cleaning | Brush off loose debris | Prevents grime buildup |

| Deep Cleaning | Use mild soap/vinegar solution | Removes oil and dirt without damage |

| Drying | Air dry with newspaper stuffing | Preserves material integrity |

| Conditioning | Apply leather conditioner seasonally | Prevents cracking, maintains flexibility |

| Inspection | Check soles and laces regularly | Ensures ongoing safety and effectiveness |

Protect Your Workforce with Durable, High-Quality Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including superior oil-resistant models designed for demanding environments.

By partnering with us, you gain access to:

- Durability: Boots built to withstand rigorous cleaning and maintenance routines.

- Reliability: Consistent quality that ensures worker safety shift after shift.

- Expertise: A trusted manufacturer with deep industry knowledge.

Ensure your team has the best protection. Contact 3515 today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How do the polarization and gain characteristics of industrial RFID antennas affect the identification of safety shoes?

- What additional safety features do modern safety Wellington boots offer? Enhanced Protection for Hazardous Workplaces

- How do safety shoes protect against impacts and vibrations? Maximize Safety and Agility in Rock Breaking & Drilling

- What specialist protections can safety boots offer? Select the Right Defense for Your Job

- What additional protections are defined by the EN ISO 20345 norm? Match Footwear to Specific Hazards

- Why must micro-friction control be considered in the technical design of diabetic footwear? Prevent Ulcers & Shear

- How do professional-grade safety shoes contribute to accident prevention? Reduce Risk with Advanced PPE Footwear

- What are the consequences of failing to comply with OSHA footwear regulations? Avoid Fines & Protect Your Business