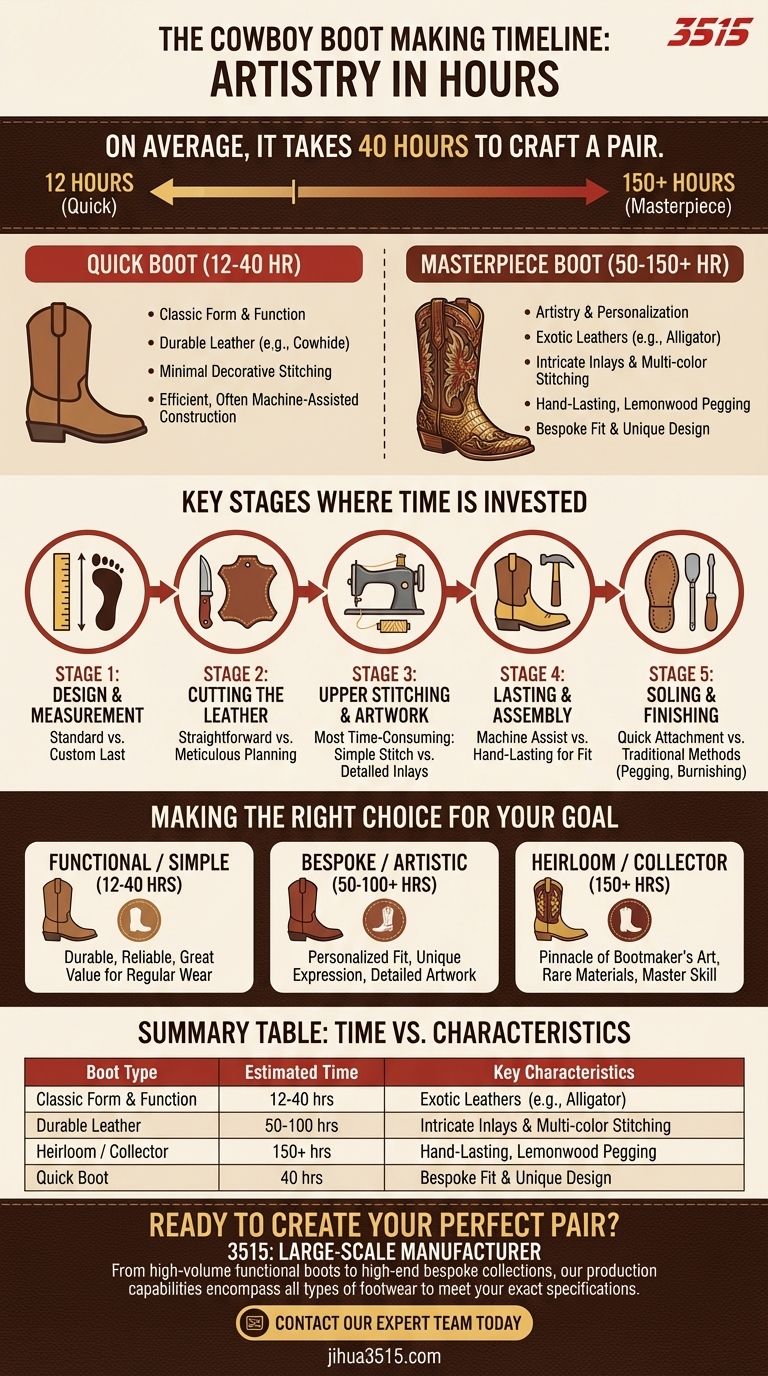

On average, crafting a pair of cowboy boots takes a bootmaker around 40 hours of focused work. However, this is merely a baseline, as the total time can range from as little as 12 hours for a simple, unadorned pair to over 150 hours for a highly intricate, bespoke creation. The true duration is a direct reflection of the complexity of the design and the construction methods employed.

The significant variation in bootmaking time isn't about manufacturing speed; it's a measure of artistry and personalization. The core difference between a 12-hour boot and a 150-hour boot lies in the level of custom detail, hand-tooling, and structural integrity built into every step.

What Defines a 12-Hour vs. a 150-Hour Boot?

The vast difference in production time comes down to specific choices in materials, decoration, and construction. A simpler boot prioritizes function and efficiency, while a complex, bespoke boot is a testament to meticulous, time-consuming craftsmanship.

The Anatomy of a Quick (12-40 Hour) Boot

A boot made in this timeframe is focused on classic form and function.

It typically features a single type of durable leather, like cowhide, with minimal decorative stitching. The construction is clean and efficient, likely using more machine assistance to ensure precision and speed without sacrificing core quality.

The Elements of a Masterpiece (50-150+ Hour) Boot

This level of work transforms the boot from footwear into a piece of art.

The extended time is invested in complex decorative elements like multi-colored thread stitching, intricate inlays (pieces of leather set into the boot), or overlays (pieces stitched on top). It may also involve exotic leathers that require precise cutting and matching, along with fully manual construction techniques like hand-lasting and lemonwood pegging for the soles.

Key Stages Where Time is Invested

Each step of the bootmaking process presents an opportunity to either streamline production or invest deeply in detail and quality.

Stage 1: Design and Measurement

A standard-size boot requires minimal design time. A custom boot, however, begins with detailed measurements of the foot and leg, followed by the creation of a unique pattern and a personalized last (the foot-shaped mold).

Stage 2: Cutting the Leather

Cutting standard cowhide is a straightforward process. Working with exotic skins like alligator or ostrich is far more demanding, as the bootmaker must meticulously plan each cut to highlight the material's natural pattern and avoid imperfections.

Stage 3: The Upper Stitching and Artwork

This is often the most time-consuming stage. A simple stitch pattern might take a few hours. A complex, multi-colored design with detailed inlays can easily consume dozens of hours of highly skilled work at the sewing machine.

Stage 4: Lasting and Assembly

Lasting is the process of stretching and shaping the leather upper over the last. While machines can assist, hand-lasting allows the bootmaker to perfectly mold the leather to the unique contours of the custom last, ensuring an unparalleled fit. This manual process takes significantly more time and skill.

Stage 5: Soling and Finishing

Attaching the sole can be a relatively quick process. However, traditional methods, such as securing the sole with hand-hammered lemonwood pegs, add considerable time, effort, and durability. The final finishing, sanding, and burnishing are also done by hand, adding hours to achieve a flawless look.

Understanding the Trade-offs: Speed vs. Craftsmanship

It's crucial to understand that a faster production time does not necessarily mean a "bad" boot. It simply reflects a different set of priorities.

The Case for Efficiency

Boots in the 12-40 hour range are the workhorses of the industry. They provide excellent durability, classic style, and great value. They are built for reliability and are accessible to a wider audience.

The Value of Time

The extended hours invested in a high-end boot are a direct investment in fit, individuality, and longevity. The meticulous hand-work and artistic detail result in a product that is not only unique but is often more comfortable and durable over the long term.

Making the Right Choice for Your Goal

Understanding the time commitment helps you align your expectations with the right type of boot for your needs.

- If your primary focus is a durable, functional boot for regular wear: A well-made boot in the 20-40 hour range offers a perfect balance of quality and value.

- If your primary focus is a personalized fit and unique artistic expression: Be prepared to invest in a boot that takes 50-100+ hours, allowing for custom measurements and detailed artwork.

- If your primary focus is a true heirloom or collector's item: The 150+ hour creations represent the absolute pinnacle of the bootmaker's art, combining rare materials and master-level skill.

Ultimately, the time it takes to make a pair of cowboy boots is a direct measure of the human skill and artistry invested in their creation.

Summary Table:

| Boot Type | Estimated Time | Key Characteristics |

|---|---|---|

| Functional / Simple | 12 - 40 hours | Durable leather, minimal stitching, efficient construction |

| Bespoke / Artistic | 50 - 150+ hours | Custom fit, exotic leathers, intricate inlays & hand-tooling |

Ready to create your perfect pair of boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether you need a reliable, high-volume line of functional boots or are looking to develop a unique, high-end bespoke collection, our production capabilities encompass all types of shoes and boots to meet your exact specifications and timeline.

Contact our expert team today to discuss your project and discover how we can bring quality and craftsmanship to your brand.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

People Also Ask

- Are lace-to-toe boots more comfortable than regular boots? Unlock a Custom Fit for Your Feet

- What are the features of sharkskin leather in cowboy boots? Unmatched Durability & Style

- Why is the toe box important in a walking shoe? Unlock Natural Foot Function & Comfort

- What type of winter boots are suitable for city or town use? Find the Perfect Urban Winter Boots

- What materials are best for breathable walking shoes? Find Your Perfect Fit for All-Day Comfort

- Where is the best place to buy walking shoes? Find the Perfect Fit for Your Feet

- What practical advice was given regarding snake-proof gear selection? Prioritize Proven Gear for Ultimate Safety

- Why is insulation rating important in winter boots? Choose the Right Warmth for Your Activity