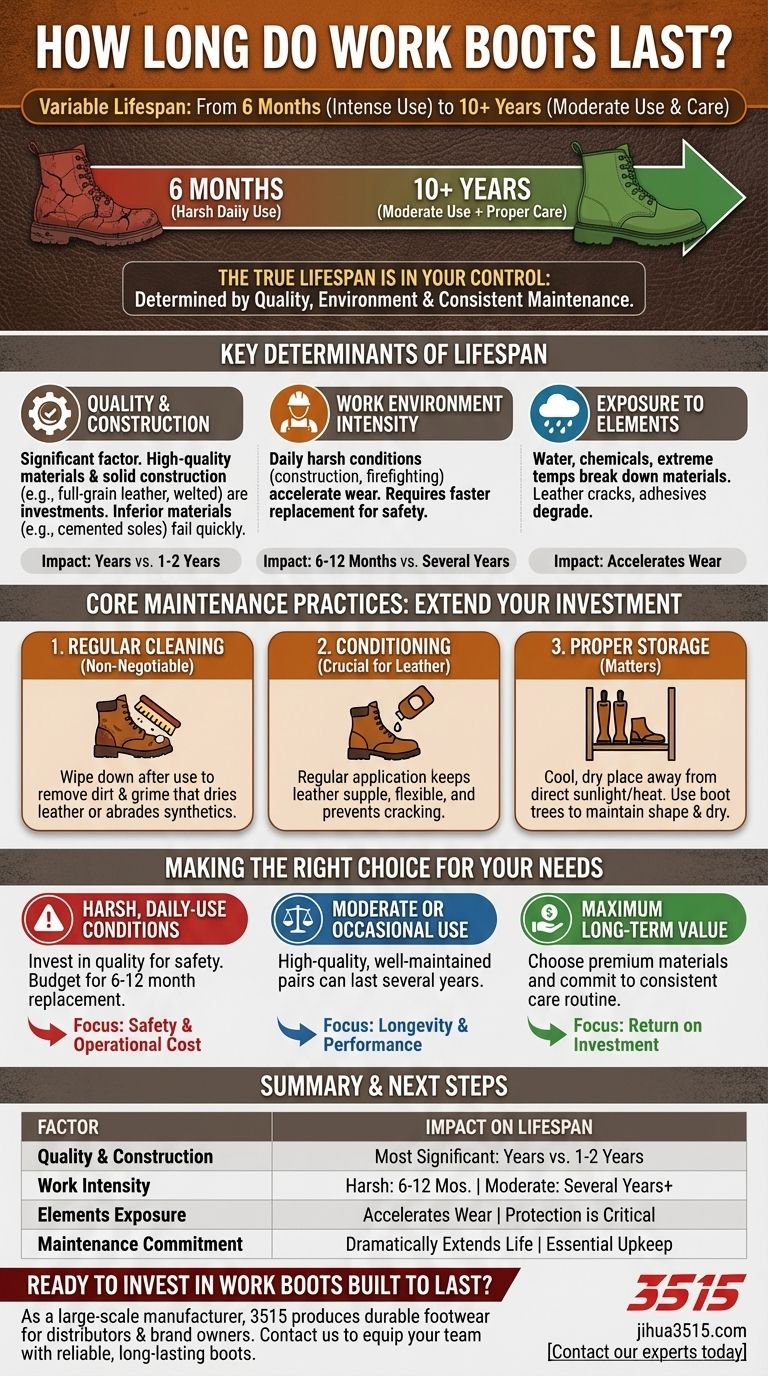

With proper care, a quality pair of work boots can last anywhere from six months in intense, daily-use environments to well over a decade for more moderate use. The wide range in lifespan is not determined by time alone, but by a combination of the boot's initial quality, the harshness of your work conditions, and your commitment to regular maintenance.

The true lifespan of your work boots is an outcome you actively control. It is determined less by a manufacturer's estimate and more by your investment in high-quality materials and consistent, proper care.

What Determines a Work Boot's Lifespan?

Several key factors work together to dictate how long your boots will provide reliable protection and support. Understanding them helps you set realistic expectations.

The Quality of Materials and Construction

The single most significant factor is the quality of the boot itself. High-quality boots made with durable materials and solid construction methods are an investment in longevity.

In contrast, boots made with inferior materials or cemented soles may fail within a year or two, regardless of how well you care for them.

The Intensity of Your Work Environment

A boot's lifespan is directly tied to its daily workload. Boots worn every day in harsh conditions like construction or firefighting will naturally wear out faster than those used in less demanding settings.

For the most intense jobs, even high-quality boots may need replacement every six to twelve months to ensure continued safety and support.

Exposure to the Elements

Constant exposure to water, extreme temperatures, or chemicals accelerates the breakdown of materials. Leather can dry and crack, while adhesives and synthetics can degrade.

Protecting your boots from these elements through waterproofing and proper storage is critical for extending their life.

The Core Practices for Extending Boot Life

Simple, consistent maintenance can dramatically increase the return on your investment. Think of it as essential upkeep for a critical piece of equipment.

Regular Cleaning is Non-Negotiable

Dirt and grime draw moisture out of leather and can wear away at synthetic materials. Wiping down your boots after use is the first line of defense.

For leather, this prevents the buildup that leads to drying and cracking. For synthetics, it removes abrasive particles.

Conditioning is Crucial for Leather

Leather is a natural skin that needs moisture to stay flexible and strong. Regular conditioning after cleaning keeps the leather supple and prevents it from becoming brittle.

This step is vital for avoiding the cracks and tears that permanently damage the boot's structure.

Proper Storage Matters

Never leave your boots in extreme heat or cold, such as in a car trunk. Store them in a cool, dry place away from direct sunlight.

Using boot trees or stuffing them with newspaper helps them maintain their shape and allows them to dry properly, preventing material breakdown and odor.

Understanding the Trade-offs

Choosing the right boot involves balancing cost, durability, and the reality of your job.

The Upfront Cost vs. Long-Term Value

High-quality boots from reputable brands cost more initially. However, their superior materials and durable construction mean they can last for many years, making them more cost-effective over time.

Cheap boots are a false economy; their frequent need for replacement often ends up costing more in the long run.

The "Six-Month" Reality for Heavy Use

For those in extremely demanding fields, the primary function of a boot is safety and support. Even with perfect care, the internal support structures, midsoles, and overall integrity can break down.

In these cases, replacing boots every 6-12 months is not a sign of poor quality but a necessary part of ensuring your on-the-job safety.

The Limits of Aftercare

Maintenance can extend the life of a well-made boot, but it cannot fix fundamental flaws. No amount of cleaning or conditioning can compensate for poor-quality leather, weak stitching, or inferior sole construction.

Making the Right Choice for Your Needs

Your approach should match your specific work environment and priorities.

- If you work in harsh, daily-use conditions: Invest in quality for maximum safety and comfort, but budget for a 6 to 12-month replacement cycle as a necessary operational cost.

- If your work involves moderate or occasional use: A high-quality, well-maintained pair of boots can easily last for several years, with some lasting a decade or more.

- If your priority is maximum long-term value: Choose boots with high-quality, full-grain leather and a durable construction method, and commit to a consistent cleaning and conditioning routine.

Ultimately, treating your work boots as a critical tool, not just footwear, is the key to their longevity.

Summary Table:

| Factor | Impact on Lifespan |

|---|---|

| Material & Construction Quality | Most significant factor. High-quality boots last years; cheap boots may fail in 1-2 years. |

| Work Environment Intensity | Harsh daily use (e.g., construction): 6-12 months. Moderate/occasional use: several years to a decade+. |

| Exposure to Elements | Water, chemicals, extreme temps accelerate wear. Proper protection is critical. |

| Commitment to Maintenance | Regular cleaning, conditioning (for leather), and proper storage dramatically extend boot life. |

Ready to invest in work boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work shoes and boots, engineered for longevity and performance in any environment.

Let us help you equip your team with reliable footwear that maximizes your return on investment. Contact our experts today to discuss your specific needs and discover the 3515 difference.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What types of electrical hazard protection are available in work boots? EH vs. SD Safety Explained

- What standard should work boots meet for safety in Australia? Ensure AS 2210.3:2019 Compliance

- What are the advantages of using snowshoeing boots for winter biking? Unbeatable Warmth & Value on Flat Pedals

- What type of boot construction is required by NFPA standards? Essential Laced Design for Wildland Firefighters

- How does nanotechnology improve composite toe work boots? Achieve Lighter, More Comfortable Protection

- What are the characteristics of cowboy work boots? Discover the Hybrid of Style & Safety

- What are some modern variations of engineer boots? A Guide to Contemporary Styles & Materials

- How can heavy duty boots be weatherproofed? A Step-by-Step Guide to Lasting Protection