At its core, the electrical protection available in work boots falls into two distinct and opposing categories: one designed to insulate you from a live electrical current, and the other designed to safely ground you to prevent static discharge. Each serves a completely different safety purpose and is engineered for specific work environments.

The fundamental choice in electrical boot protection is between Electrical Hazard (EH) boots, which insulate you to prevent shock from live circuits, and Anti-Static (SD) boots, which safely conduct static charge away from your body to protect sensitive equipment or prevent ignition. These two functions are mutually exclusive.

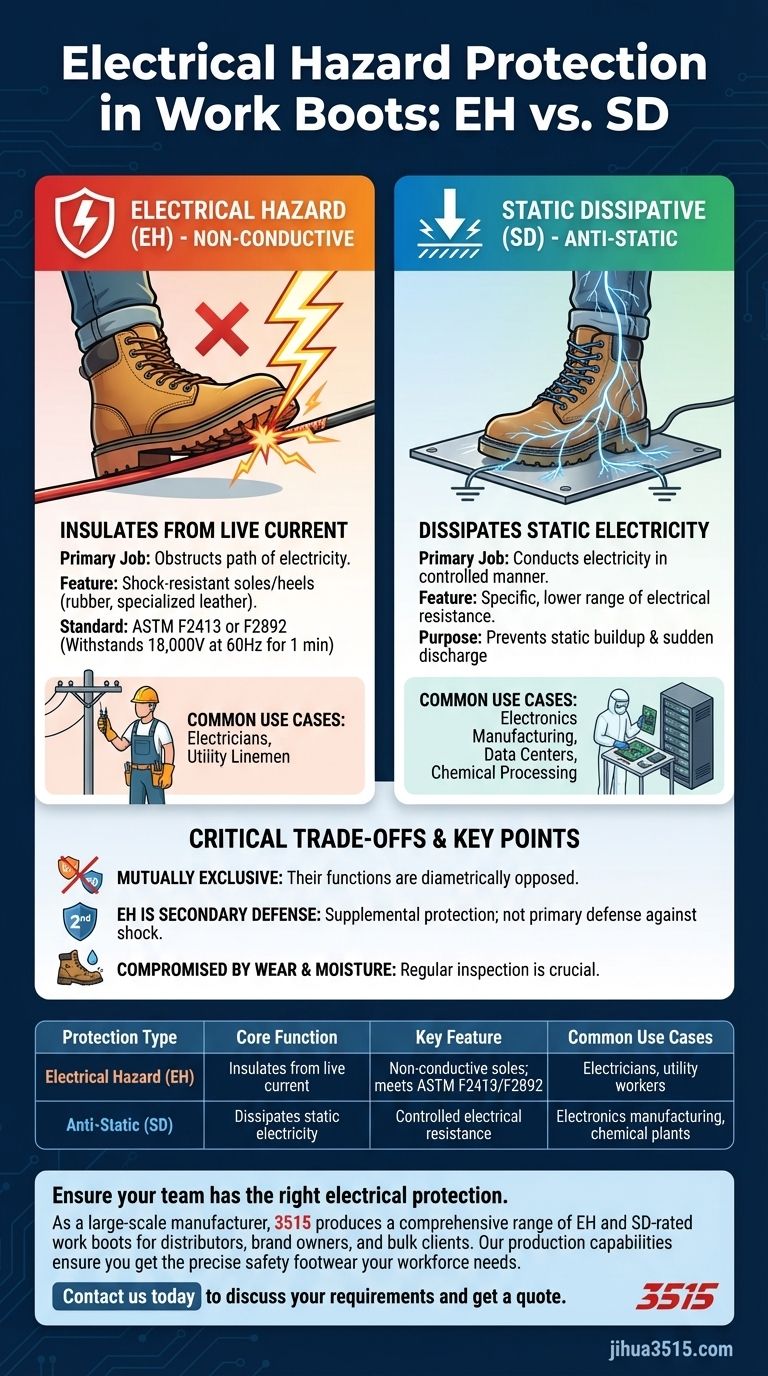

The Two Pillars of Electrical Protection

Understanding the core purpose of each type of protection is critical. Choosing the wrong one can create a false sense of security or even introduce a new hazard into your environment.

Non-Conductive (EH) Boots: Your Personal Insulation

Electrical Hazard (EH) rated boots are designed to be a secondary source of protection against accidental electrocution. Their primary job is to obstruct the path of electricity.

These boots feature shock-resistant soles and heels made from non-conductive materials like rubber or specialized leather. This construction insulates you from the ground, reducing the chance of your body completing an electrical circuit if you step on a live wire.

To be certified, EH-rated footwear must meet ASTM safety standards (F2413 for safety toe or F2892 for non-safety toe boots). This means they can withstand the application of 18,000 volts at 60 Hz for one minute without dangerous current flow.

This type of protection is essential for electricians, utility linemen, and anyone working in proximity to exposed or potentially damaged electrical equipment.

Anti-Static (SD) Boots: Preventing the Spark

In contrast, Anti-Static or Static Dissipative (SD) boots are designed to do the opposite of EH boots: they conduct electricity, but in a highly controlled manner.

Their purpose is to reduce the buildup of static electricity on your body by safely dissipating it through your footwear and into the ground.

This is critical in environments where a sudden electrostatic discharge could damage sensitive electronic components or ignite flammable vapors, dust, or materials. SD boots are common for workers in electronics manufacturing, data centers, and certain chemical processing facilities.

Understanding the Critical Trade-offs

The distinction between insulating and dissipating electricity is absolute. A misunderstanding of these principles can lead to significant safety failures.

EH and Anti-Static are Mutually Exclusive

A boot cannot provide both EH and Anti-Static protection. Their functions are diametrically opposed. EH boots have very high electrical resistance to insulate you, while SD boots have a specific, lower range of resistance to allow static to dissipate.

EH Protection is a Secondary Defense

It is crucial to remember that EH-rated footwear is a supplemental form of protection. It should never be considered the primary defense against electrical shock. Proper safety protocols, such as de-energizing circuits and using appropriate personal protective equipment (PPE), must always be the first line of defense.

Environmental Factors Can Compromise Safety

The protective qualities of any electrical boot can be compromised. Excessive wear, deep punctures in the sole, or even exposure to excessive moisture can negate the boot's EH rating. Regular inspection of your footwear is a non-negotiable part of your safety routine.

Making the Right Choice for Your Goal

Selecting the correct boot requires a clear understanding of the specific electrical hazard you face in your daily work.

- If your primary focus is protecting yourself from shock: You need boots with an Electrical Hazard (EH) rating that insulates you from ground.

- If your primary focus is protecting sensitive equipment or preventing ignition: You need Anti-Static (SD) boots that safely dissipate static buildup from your body.

- If you have no specific electrical hazards: You can focus on other critical safety features like toe protection (steel, composite, or alloy) and puncture resistance.

Ultimately, choosing the right footwear is a critical decision that directly impacts your safety and the integrity of your work environment.

Summary Table:

| Protection Type | Core Function | Key Feature | Common Use Cases |

|---|---|---|---|

| Electrical Hazard (EH) | Insulates from live current | Non-conductive soles; meets ASTM F2413/F2892 | Electricians, utility workers |

| Anti-Static (SD) | Dissipates static electricity | Controlled electrical resistance | Electronics manufacturing, chemical plants |

Ensure your team has the right electrical protection.

As a large-scale manufacturer, 3515 produces a comprehensive range of EH and SD-rated work boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the precise safety footwear your workforce needs.

Contact us today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the key features of firefighter work boots? Essential Protection & Support for First Responders

- What are the characteristics of cowboy work boots? Discover the Hybrid of Style & Safety

- Do all injection-molded work boots have the same drawbacks? The Truth About Material Quality

- What materials are best for waterproof work boots? Choose the Right System for Your Job

- How can you freshen smelly work boots? A Permanent Guide to Eliminating Odor

- Why is cushioning and arch support important for a mechanic's work footwear? Protect Your Body from Concrete Floors

- What are the key considerations for firefighters' boots besides hazard protection? Unlock Peak Performance & Safety

- What are the advantages of using PU for work boots? Lightweight Comfort & Durability Explained