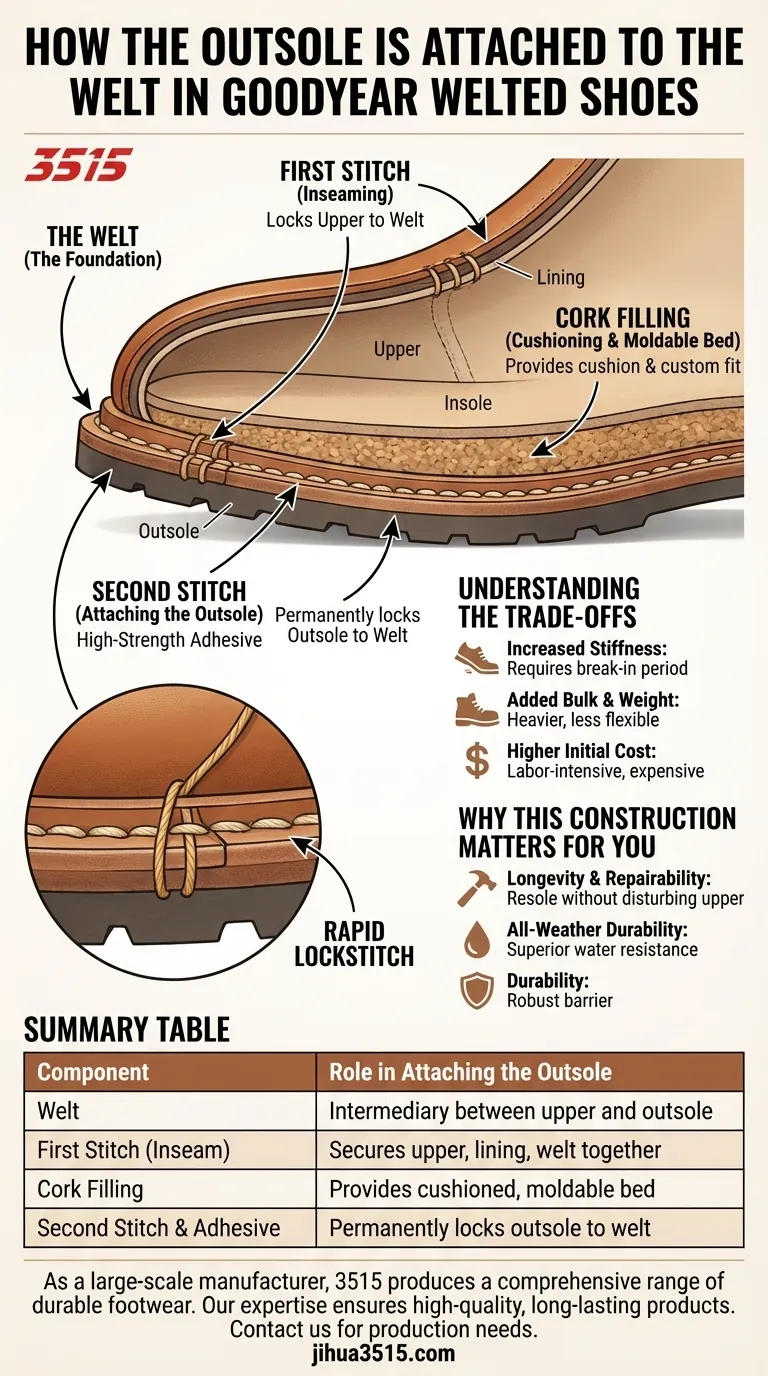

In a Goodyear welted shoe, the outsole is secured to the welt through a robust combination of stitching and a high-strength adhesive. This dual-method approach creates an exceptionally strong bond that is central to the shoe's durability and repairability.

The core principle of the Goodyear welt is its two-level stitching system. By attaching the outsole to the welt—and not directly to the upper—the shoe gains significant durability and can be resoled multiple times without compromising its core structure.

Deconstructing the Goodyear Welt Method

To fully understand how the outsole attaches, it's essential to see its place within the overall construction process. The Goodyear welt is a sophisticated method involving several distinct components and two separate stitches.

The Role of the Welt

The welt is the foundational component in this process. It is a dedicated strip of leather, roughly half an inch wide, that runs along the perimeter of the shoe. Its sole purpose is to act as an intermediary, connecting the upper part of the shoe to the outsole.

The First Stitch: Inseaming

Before the outsole is even involved, the first critical connection is made. A stitch, known as the inseam, runs through the shoe's upper, the lining, and the welt. This locks the top part of the shoe securely to the welt, creating a stable platform.

Creating the Foundation with Cork

With the welt attached, a cavity is formed between the insole and what will be the outsole. This space is typically filled with a layer of granulated cork and adhesive. This cork filling provides cushioning, insulation, and over time, molds to the unique shape of your foot for a custom fit.

The Second Stitch: Attaching the Outsole

This is the final and most visible step. The outsole is first coated with a powerful adhesive, such as contact cement, and pressed firmly onto the cork bed and welt. Then, a second, heavy-duty stitch—often a rapid lockstitch—is sewn directly through the outsole and the welt, permanently locking them together. This is the stitch you can typically see running around the edge of the sole.

Understanding the Trade-offs

While renowned for its durability, the Goodyear welt construction method has inherent characteristics that are important to acknowledge.

Increased Stiffness

The multiple layers of leather, cork, and heavy stitching make Goodyear welted shoes notoriously stiff when new. They require a significant "break-in" period for the materials to soften and the cork bed to mold to your foot.

Added Bulk and Weight

This construction method is not sleek. The welt adds visual and physical bulk around the edge of the shoe, resulting in a heavier and less flexible final product compared to more streamlined methods like Blake stitching.

Higher Initial Cost

The complexity of the two-level stitching process, combined with the amount of material used, makes Goodyear welted shoes more labor-intensive and expensive to produce. The cost reflects the shoe's potential for longevity, not its out-of-the-box comfort.

Why This Construction Matters for You

Choosing a shoe is about matching its construction to your needs. Understanding how the outsole is attached helps you make a more informed decision.

- If your primary focus is longevity and repairability: The Goodyear welt is unparalleled, as the ability to replace the outsole without disturbing the upper is its defining feature.

- If your primary focus is all-weather durability: The welt creates a more robust barrier between the upper and the sole, offering superior water resistance compared to many other construction types.

- If your primary focus is immediate comfort and flexibility: You may find the initial stiffness and break-in period of a Goodyear welt to be a significant drawback.

Knowing this key construction detail empowers you to invest in footwear that truly aligns with your long-term expectations for performance and value.

Summary Table:

| Component | Role in Attaching the Outsole |

|---|---|

| Welt | Leather strip that acts as an intermediary between the upper and the outsole. |

| First Stitch (Inseam) | Secures the upper, lining, and welt together, creating a stable platform. |

| Cork Filling | Provides a cushioned, moldable bed for the outsole to be attached to. |

| Second Stitch & Adhesive | A heavy-duty stitch and high-strength adhesive permanently lock the outsole to the welt. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in robust construction methods like Goodyear welting ensures your customers receive high-quality, long-lasting products. Let us help you build a superior footwear line. Contact our team today to discuss your production needs.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

People Also Ask

- What tips are recommended for buying men's dress shoes? A Guide to Fit, Quality & Long-Term Value

- How should saddle soap be applied to leather shoes? A Step-by-Step Guide to Deep Cleaning

- How do monk strap shoes differ from other men's dress shoes? The Buckle Closure Explained

- What factors influence the decision between Goodyear welted and cemented shoes? Make the Right Choice for Your Needs

- How does heel height in formal footwear influence energy consumption and lower limb biomechanics? Expert Analysis

- What is the historical origin of Goodyear Welted construction? Discover the 19th Century Revolution

- What is the function of superior customer experience for dress and formal shoes? Build Loyalty with Service Excellence

- How can you remove salt stains from leather dress shoes? Save Your Shoes with a Simple Vinegar Solution