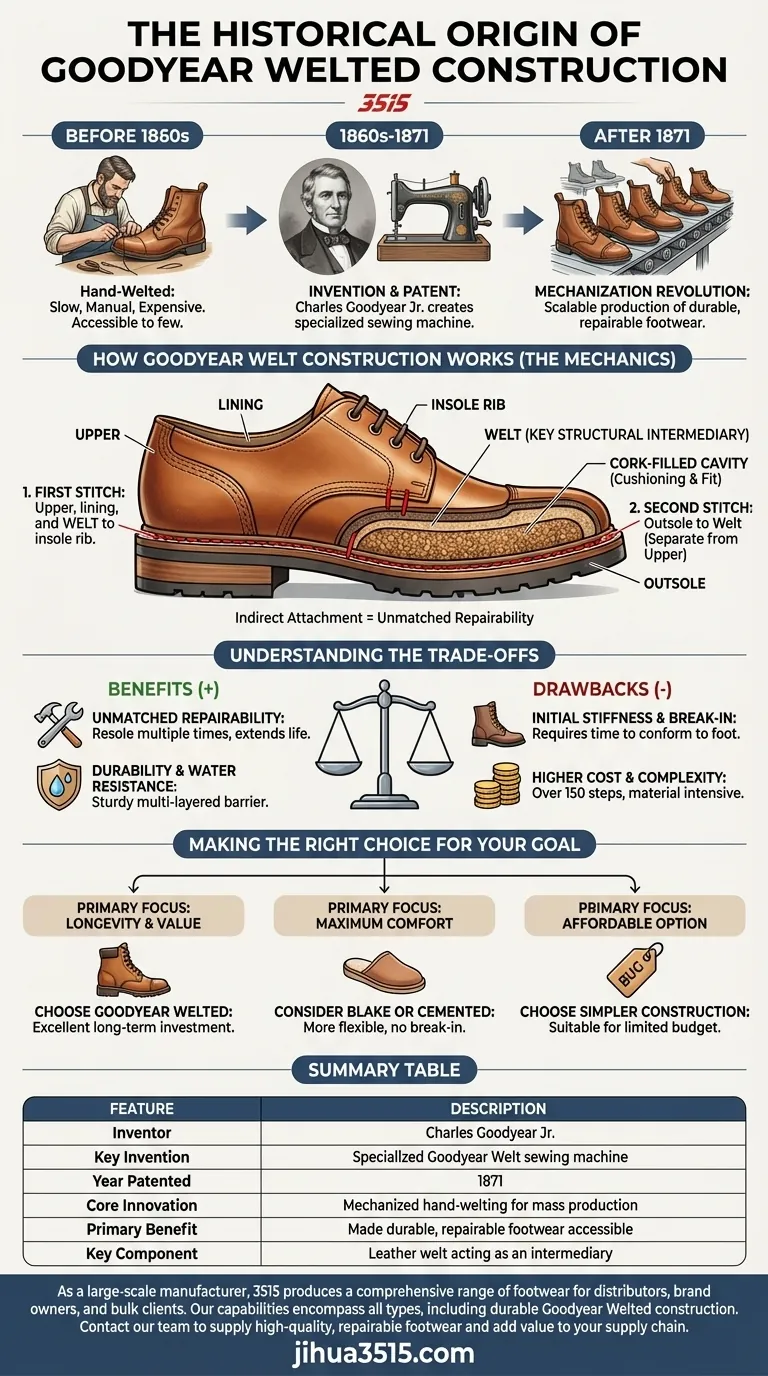

The Goodyear Welt construction method was invented by Charles Goodyear Jr. in the 1860s and was fully realized with his patent for the specialized sewing machine in 1871. This invention was not merely an improvement; it was a revolution that mechanized a time-honored but slow hand-sewing process, making exceptionally durable footwear accessible for mass production.

The core problem Goodyear Jr. solved was scalability. His invention allowed manufacturers to produce footwear with the durability and repairability of bespoke, hand-welted shoes but at the speed and volume demanded by the industrial era.

The Problem It Solved: From Handcraft to Industry Standard

Before the late 19th century, creating durable footwear was an intensely manual and time-consuming process. The Goodyear Welt machine fundamentally changed the economics and availability of high-quality shoes and boots.

Before Mechanization

The most durable shoes were made using a hand-welted method, where a skilled artisan would meticulously stitch everything by hand. This resulted in a superior product that was expensive and accessible to only a few.

An Industrial Revolution Answer

Charles Goodyear Jr.'s machine automated the most critical and difficult step: attaching the sole to the upper. The machine could rapidly stitch a welt—a strip of leather—to the shoe's upper and insole, creating a robust platform for attaching the outsole.

The Impact on Footwear

This mechanization drastically reduced the time and skill required to produce a long-lasting shoe. It became the gold standard for quality boots and dress shoes, establishing a benchmark for durability and repairability that persists to this day.

How Goodyear Welt Construction Works

The genius of the Goodyear Welt lies in its indirect attachment method. The outsole is not stitched directly to the upper, which is the key to its longevity.

The Two-Level Stitch

The process uses two independent stitches. First, the machine stitches the upper, lining, and welt to a "rib" on the insole. This creates a single, solid unit.

The Role of the Welt

The welt acts as a structural intermediary. The outsole is then stitched directly to this welt, completing the construction. This means the stitches holding the outsole on are completely separate from those holding the upper together.

The Cork-Filled Cavity

This construction method creates a cavity between the insole and the outsole. This space is filled with a layer of granulated cork, which provides cushioning and breathability. Over time, the cork molds to the shape of your foot, creating a custom-like fit.

Understanding the Trade-offs

While considered a premium construction method, the Goodyear Welt has a distinct set of characteristics that are important to understand.

Benefit: Unmatched Repairability

Because the outsole is stitched to the welt and not the upper, a cobbler can easily remove the old sole and stitch on a new one multiple times. This dramatically extends the life of the footwear without ever compromising the shoe's core structure.

Benefit: Durability and Water Resistance

The multi-layered construction and strong lockstitching create an exceptionally sturdy shoe. The welt provides an additional barrier against water seeping in from the bottom, making it more weather-resistant than simpler construction methods.

Drawback: Initial Stiffness and Break-In

The trade-off for this robust construction is initial stiffness. A new pair of Goodyear Welted shoes often requires a break-in period as the thick insole and cork footbed conform to your foot.

Drawback: Higher Cost and Complexity

The process is materially intensive and complex, involving over 150 different steps. This results in a higher upfront cost compared to shoes with cemented or Blake-stitched soles.

Making the Right Choice for Your Goal

Understanding this history helps you decide if this construction method aligns with your priorities for a pair of shoes or boots.

- If your primary focus is longevity and long-term value: Goodyear Welted construction is an excellent investment, as the ability to resole the footwear extends its life for years, often decades.

- If your primary focus is maximum comfort straight out of the box: Be prepared for a break-in period, or consider a more flexible construction like a Blake stitch or cemented sole.

- If your primary focus is finding the most affordable option: A simpler and less expensive construction method will be a more suitable choice for a limited budget.

Choosing Goodyear Welted footwear is an investment in a time-tested method built on quality, durability, and sustainable craftsmanship.

Summary Table:

| Feature | Description |

|---|---|

| Inventor | Charles Goodyear Jr. |

| Key Invention | Specialized Goodyear Welt sewing machine |

| Year Patented | 1871 |

| Core Innovation | Mechanized the hand-welting process for mass production |

| Primary Benefit | Made durable, repairable footwear accessible |

| Key Component | Leather welt acting as an intermediary between upper and sole |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the durable and long-lasting Goodyear Welted construction. If you are looking for a reliable manufacturing partner to supply high-quality, repairable footwear, contact our team today to discuss your project and discover how we can add value to your supply chain.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear