In the world of shoe manufacturing, Goodyear Welted construction is widely regarded as one of the finest, most durable, and most repairable methods available. Developed in the 19th century, it involves stitching a strip of leather—the "welt"—to the shoe's upper and insole, which is then stitched to the outsole, creating a remarkably robust and long-lasting structure.

The core value of a Goodyear welt is not just its initial strength, but its unparalleled ability to be resoled multiple times. This transforms a high-quality shoe from a disposable item into a long-term investment that can last for decades with proper care.

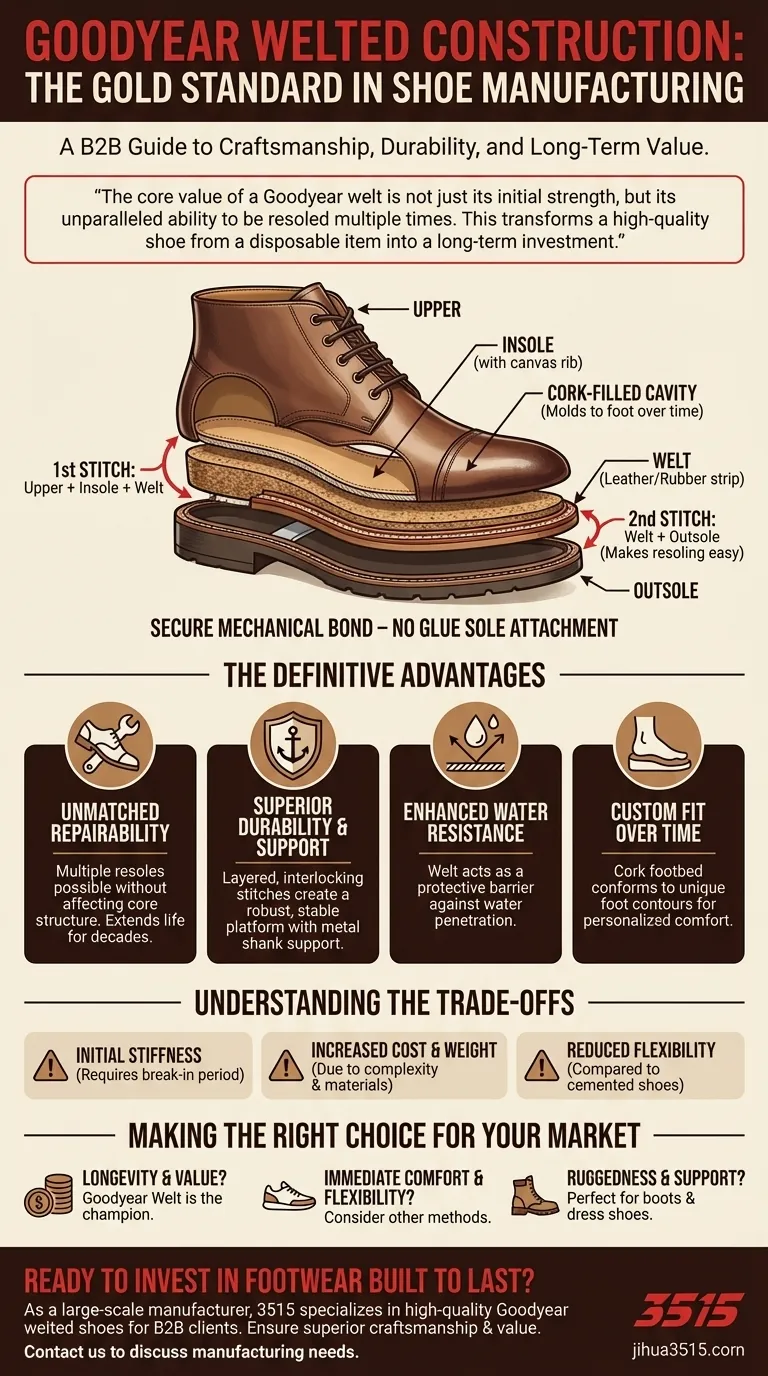

Deconstructing the Goodyear Welt

To understand why this method is so highly esteemed, you must first understand its distinct, multi-layered assembly process. Unlike simpler methods where the sole is merely glued on, the Goodyear welt creates a secure mechanical bond.

The Key Components

The process relies on several crucial parts: the upper (the main body of the shoe), the insole (inside the shoe, under your foot), and a canvas rib cemented to the insole. A strip of leather, rubber, or plastic known as the welt is the key intermediary.

A Two-Level Stitching Process

The construction involves two independent stitches. First, the upper is stitched to the welt and the canvas rib on the insole. This initial stitch creates a strong, contained unit.

Second, the outsole is stitched directly to the welt. This second stitch is what makes the shoe so easy to repair.

The Cork-Filled Cavity

This two-level process creates a cavity between the insole and the outsole. This space is filled with a layer of cork, which provides cushioning, insulation, and breathability. Over time, this cork layer molds to the shape of your foot.

The Definitive Advantages of Goodyear Welt Construction

The labor-intensive nature of this method directly translates into tangible benefits for the wearer, centered around longevity and comfort.

Unmatched Repairability

This is the primary advantage. Because the outsole is stitched to the welt rather than the upper, a cobbler can easily remove the old sole and stitch on a new one without ever disturbing the shoe's core structure. This allows for multiple resoles, dramatically extending the footwear's life.

Superior Durability and Support

The interlocking stitches and layered construction create an incredibly strong and stable platform. A metal shank is also typically embedded within the shoe, helping it retain its shape and providing excellent arch support.

Enhanced Water Resistance

The welt acts as a small wall or barrier around the edge of the shoe. This construction makes it significantly more difficult for water to penetrate the seam between the upper and the sole compared to a simple cemented shoe.

A Custom Fit Over Time

The cork footbed is a signature feature. As you wear the shoes, your body heat and pressure cause the cork to compress and conform to the unique contours of your feet, creating a personalized, custom-like fit that improves with age.

Understanding the Trade-offs

While revered, the Goodyear welt is not the perfect solution for every type of footwear or user. Objectivity requires acknowledging its inherent compromises.

Initial Stiffness

Goodyear welted shoes are known for being firm and stiff out of the box. They require a break-in period for the leather and cork to soften and mold to your foot. This initial discomfort is the trade-off for long-term custom comfort.

Increased Cost and Weight

The complexity of the process, the materials required, and the skilled labor involved make Goodyear welted shoes more expensive to produce. The additional layers also result in a heavier, more substantial shoe.

Reduced Flexibility

By its very nature, this construction is more rigid than methods where the sole is glued on. While this rigidity provides excellent support, it is less ideal for footwear where maximum flexibility is the primary goal, such as athletic sneakers.

Making the Right Choice for Your Goal

Selecting a shoe construction method depends entirely on what you value most in your footwear.

- If your primary focus is longevity and long-term value: Goodyear welting is the undisputed champion, as its repairability makes it a wise investment.

- If your primary focus is immediate comfort and flexibility: You may prefer a cemented or Blake-stitched shoe, but you will sacrifice the potential for multiple resoles.

- If your primary focus is ruggedness and support: The robust and stable platform of a Goodyear welt is perfectly suited for durable boots and dress shoes.

Ultimately, choosing Goodyear welted footwear is an investment in superior craftsmanship, exceptional durability, and a personalized fit that only improves with time.

Summary Table:

| Advantage | Description |

|---|---|

| Unmatched Repairability | Can be resoled multiple times, extending the shoe's life for decades. |

| Superior Durability | Multi-layered, stitched construction creates a robust and stable platform. |

| Enhanced Water Resistance | The welt acts as a barrier, making it harder for water to penetrate. |

| Custom Fit Over Time | Cork footbed molds to the shape of your foot for personalized comfort. |

Ready to invest in footwear built to last?

As a large-scale manufacturer, 3515 specializes in producing high-quality Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures superior craftsmanship, durability, and long-term value in every pair.

Contact us today to discuss your manufacturing needs and discover how we can bring durable, repairable footwear to your market.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How do professional dress and formal shoes accommodate metabolic conditions? Essential Footwear for Health

- What is a Spectator shoe? A Bold Statement in Two-Tone Style

- What are the main differences between formal and casual dress shoes? A Guide to Choosing the Right Shoe

- How can loafers be incorporated into a professional wardrobe? Master the Art of Boardroom-Ready Style

- How often should leather shoes be polished? A Practical Guide to Extend Their Lifespan

- What is the origin of brogue detailing on shoes? From Bog-Draining to Style Statement

- What are the methods for breaking in dress shoes? Achieve Perfect Comfort & Long-Lasting Fit

- Why is it beneficial to understand the anatomy of a dress shoe? Make a Smart, Long-Term Investment