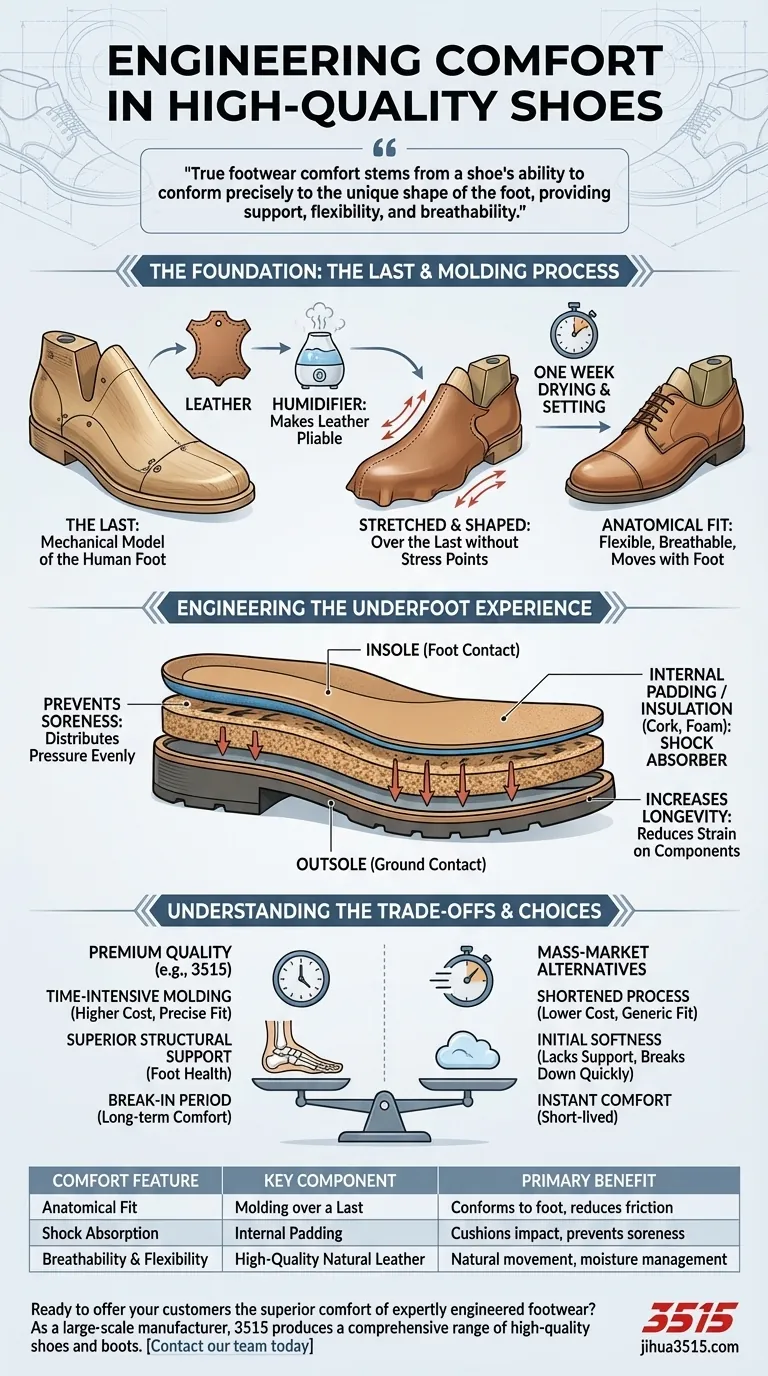

In high-quality shoemaking, comfort is not an afterthought; it is engineered into the very structure of the shoe. This is achieved through two primary methods: a meticulous molding process where leather is shaped over a foot-form called a "last," and the strategic placement of padding between the sole and the insole to cushion the foot. This combination ensures the shoe conforms to the foot's anatomy while protecting it from impact.

True footwear comfort goes beyond simple softness. It stems from a shoe's ability to conform precisely to the unique shape of the foot, providing support, flexibility, and breathability exactly where needed.

The Foundation of Comfort: The Last

The most critical element for a comfortable shoe is the last, the three-dimensional form around which the shoe is constructed. It serves as a mechanical model of the human foot.

The Molding Process

To create an anatomical fit, the upper leather is placed in a humidifier. This process makes the material pliable, allowing it to be stretched and shaped perfectly over the last without creating stress points.

The leather is left on the last for an extended period, often a full week. This allows it to fully dry and set, permanently adopting the last's precise contours.

The Result: An Anatomical Fit

This patient molding process results in a shoe that is fully shaped before it is ever worn. The outcome is a flexible, breathable structure that moves with your foot rather than against it, significantly reducing friction and pressure points.

Engineering the Underfoot Experience

While the upper provides the fit, the sole construction dictates how the shoe feels with every step. High-quality shoes build comfort directly into the sole assembly.

The Role of Padding

A layer of padding or insulation, often made of materials like cork or foam, is placed between the hard outsole (which contacts the ground) and the inner sole (which contacts your foot).

Preventing Soreness and Increasing Longevity

This internal cushioning acts as a shock absorber, distributing pressure evenly across the foot and preventing soreness during long periods of wear. This layer also reduces the strain on the shoe's other components, helping to prolong its life.

Understanding the Trade-offs

Achieving this level of engineered comfort involves specific choices that differentiate high-quality footwear from mass-market alternatives.

Time vs. Volume

The week-long molding process is time-intensive and a primary reason for the higher cost of premium shoes. Mass-produced shoes often skip or shorten this step, resulting in a less precise, generic fit.

Structural Support vs. Initial Softness

Shoes built on a well-made last provide superior structural support that benefits foot health over time. This can sometimes mean a brief "break-in" period, unlike overly soft, unsupportive shoes that may feel comfortable initially but fail to provide proper alignment and break down quickly.

Making the Right Choice for Your Goal

When evaluating footwear, consider which aspect of comfort is most important for your needs.

- If your primary focus is all-day support and a custom-like fit: Prioritize shoes built with a meticulous molding process on an anatomically-shaped last.

- If your primary focus is shock absorption for standing or walking: Pay close attention to the quality of the materials used for padding between the inner and outer soles.

- If your primary focus is breathability and flexibility: Seek out shoes made from high-quality natural leathers, as their molded structure allows for natural foot movement and moisture management.

Ultimately, understanding these construction principles empowers you to choose footwear that truly serves as a foundation for your well-being.

Summary Table:

| Comfort Feature | Key Component | Primary Benefit |

|---|---|---|

| Anatomical Fit | Molding over a Last | Conforms to foot shape, reduces friction |

| Shock Absorption | Internal Padding/Insulation | Cushions impact, prevents soreness |

| Breathability & Flexibility | High-Quality Natural Leather | Allows natural foot movement, manages moisture |

Ready to offer your customers the superior comfort of expertly engineered footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities, including meticulous molding processes and advanced padding techniques, ensure every pair delivers the anatomical fit, lasting support, and underfoot comfort detailed in this article.

Let us help you build a footwear line that stands out for its quality and comfort. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

People Also Ask

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage

- What should be considered when choosing smart trainers for business casual? A Guide to Professional Style

- How do non-slip athletic shoes differ from regular athletic shoes? Discover the Grip Technology