Modern Wellington work boots have transformed from simple waterproof footwear into highly specialized protective equipment. While they retain their iconic silhouette, the construction has evolved to include advanced materials like full-grain leather and PVC, alongside critical safety features such as steel toes, anti-static properties, and chemical resistance.

The evolution of the Wellington boot represents a shift from passive weather protection to active hazard mitigation. Today’s models are engineered systems designed to withstand specific industrial environments, from chemical plants to deep-sea fishing decks.

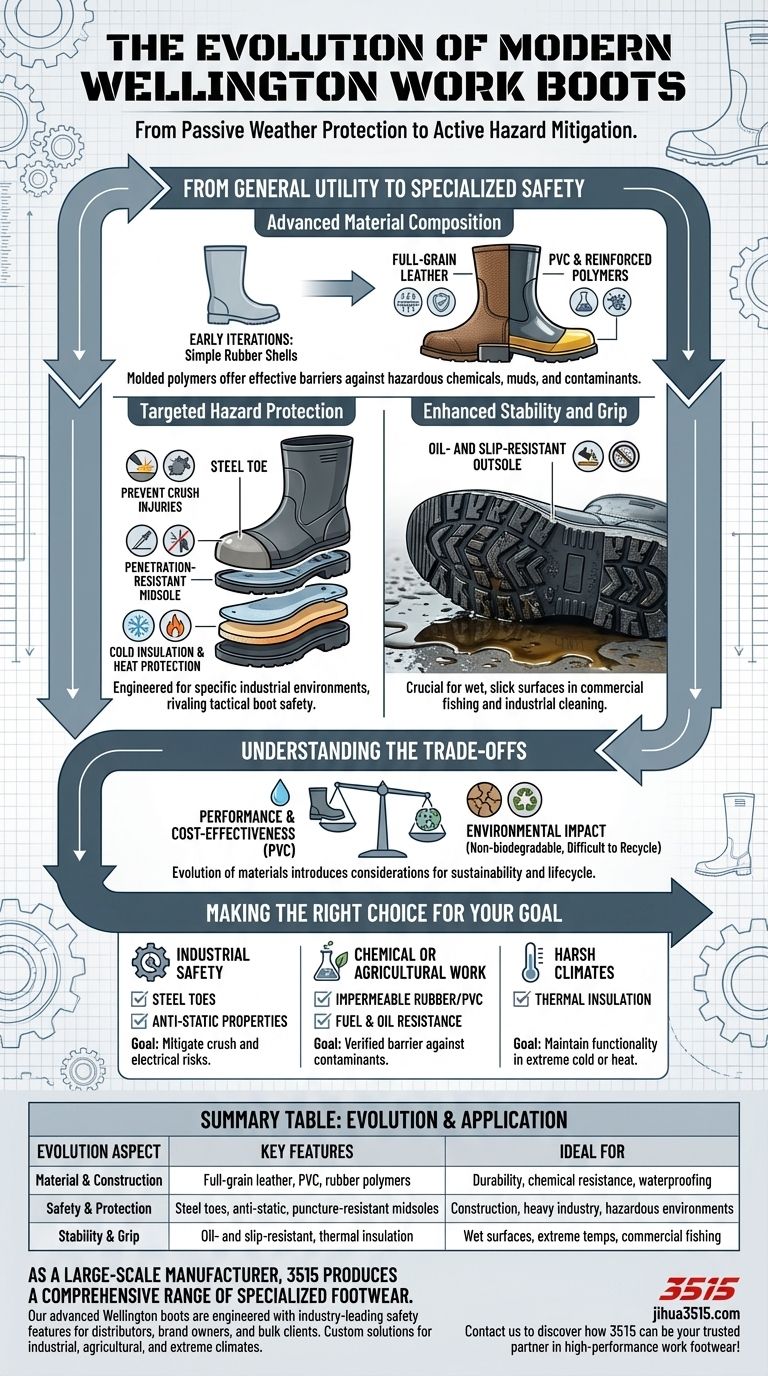

From General Utility to Specialized Safety

The modern Wellington is defined by its adaptation to specific work environments. Manufacturers have moved beyond basic waterproofing to address complex industrial risks.

Advanced Material Composition

Early iterations were simple rubber shells. Modern versions utilize full-grain leather for breathability and long-term durability, or specialized synthetic compounds for maximum impermeability.

In industrial contexts, boots are often molded entirely from rubber or reinforced polymers. This construction provides an effective barrier against hazardous chemicals, drilling muds, and biological contaminants found in agricultural settings.

Targeted Hazard Protection

Safety features now rival those of lace-up tactical boots. Steel toe protection is a standard option for preventing crush injuries in construction and heavy industry.

Beyond impact protection, modern Wellingtons often feature penetration-resistant midsoles to stop sharp objects from piercing the foot. Specialized models also include cold insulation and heat protection, allowing the boot to function in extreme temperature gradients.

Enhanced Stability and Grip

The outsole technology has seen significant upgrades to prevent workplace accidents. Modern treads are engineered to be oil- and slip-resistant.

This is particularly vital for professions like commercial fishing or industrial cleaning. The sole design ensures stability on wet, slick surfaces where standard footwear would fail.

Understanding the Trade-offs

While performance has improved, the evolution of materials introduces new considerations regarding sustainability and lifecycle management.

The Environmental Impact of PVC

A significant portion of modern Wellington boots are manufactured using Polyvinyl Chloride (PVC). While this material is excellent for waterproofing and cost-effectiveness, it is derived from oil.

The trade-off is environmental durability versus ecological impact. PVC is generally non-biodegradable and difficult to recycle, contributing to long-term pollution issues once the boots reach the end of their service life.

Making the Right Choice for Your Goal

Selecting the correct modern Wellington requires analyzing the specific hazards of your environment rather than just looking for waterproofing.

- If your primary focus is Industrial Safety: Prioritize boots with certified steel toes and anti-static properties to mitigate crush and electrical risks.

- If your primary focus is Chemical or Agricultural Work: Select boots made of impermeable rubber or PVC that offer verified fuel and oil resistance.

- If your primary focus is Harsh Climates: Look for models specifically engineered with thermal insulation to maintain functionality in extreme cold or heat.

The modern Wellington is no longer just a boot; it is a shield engineered for your specific working conditions.

Summary Table:

| Evolution Aspect | Key Features | Ideal For |

|---|---|---|

| Material & Construction | Full-grain leather, PVC, rubber polymers | Durability, chemical resistance, waterproofing |

| Safety & Protection | Steel toes, anti-static properties, puncture-resistant midsoles | Construction, heavy industry, hazardous environments |

| Stability & Grip | Oil- and slip-resistant outsoles, thermal insulation | Wet surfaces, extreme temperatures, commercial fishing |

As a large-scale manufacturer, 3515 produces a comprehensive range of specialized footwear for distributors, brand owners, and bulk clients.

Our advanced Wellington work boots are engineered with industry-leading safety features—including steel toes, chemical resistance, and superior grip—to protect your workforce in the most demanding environments. Whether you need custom solutions for industrial safety, agricultural durability, or extreme climate performance, we have the expertise and production capacity to meet your needs.

Contact us today to discuss your requirements and discover how 3515 can be your trusted partner in high-performance work footwear!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the key ASTM standards for work boots? Your Guide to Certified Footwear Safety

- How do mining boots provide electrical hazard protection? Essential Safety for Electrical Work

- What are work boots for women? Engineered for Safety, Fit, and Performance

- How can the lifespan of work boots be extended? A Proactive Maintenance Guide for Long-Lasting Footwear

- What are the advantages of leather versus synthetic work boots? A Guide to Choosing the Right Material

- What risks arise from cuts or wear in work boot outer material? A Critical Safety Breakdown

- How did monkey boots influence the popularity of lace-to-toe designs? A Look at Subcultural Style Evolution

- What are the consequences of wearing improper work shoes? Prevent Chronic Pain and Lost Productivity