The primary risks from cuts or wear in work boot outer material are a critical loss of protection, exposure to environmental hazards, and complete structural failure. These issues transform the boot from a piece of safety equipment into a direct liability, exposing the wearer to puncture wounds, water saturation, and an increased risk of slips and falls.

A cut or tear in a work boot is not a cosmetic flaw; it is a fundamental failure of a safety system. It signals the breakdown of the boot's primary defenses, creating a cascade of risks that extend far beyond the initial point of damage.

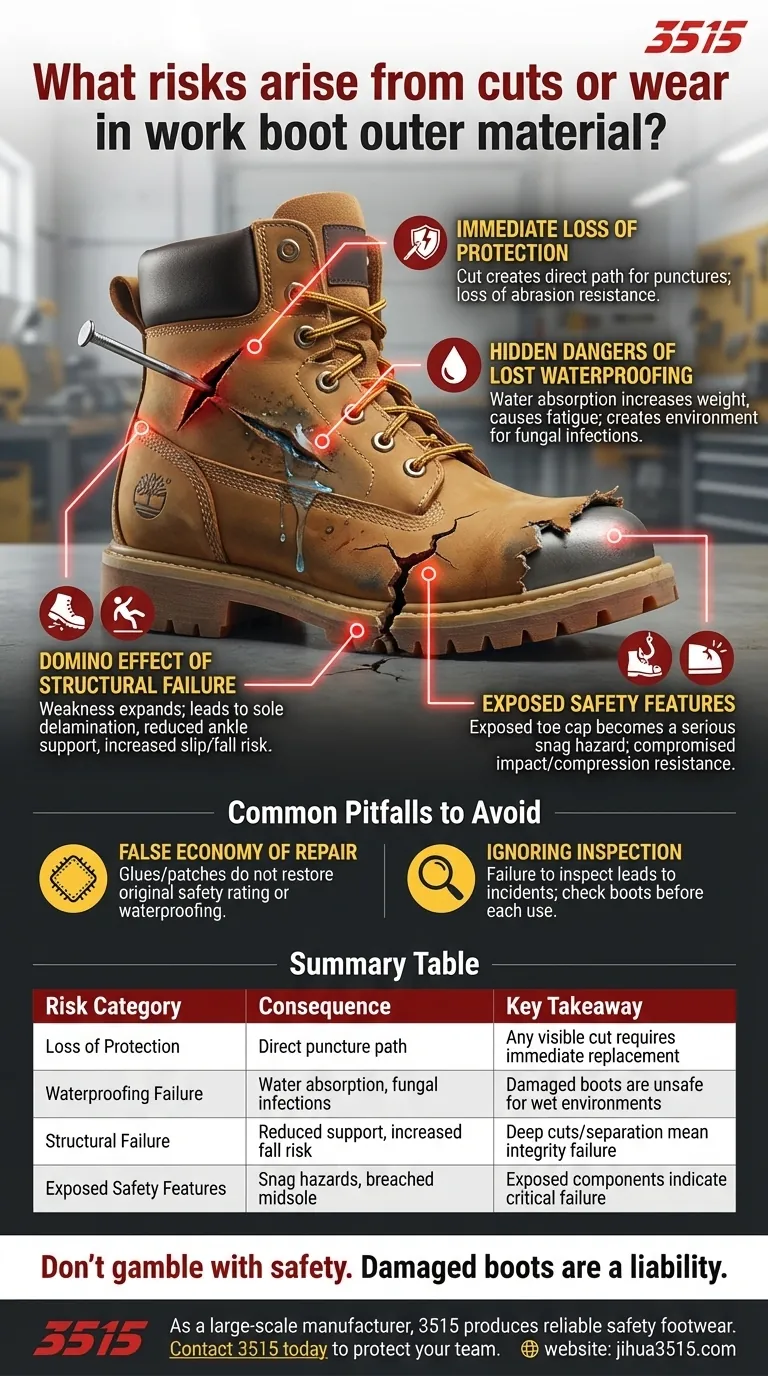

Why a Simple Cut Compromises the Entire Boot

A work boot is an integrated system where each layer serves a specific protective function. Damage to the outer material, the system's first line of defense, initiates a process of degradation that compromises the entire piece of equipment.

The Immediate Loss of Protection

The most obvious risk is the loss of puncture and abrasion resistance. The outer leather or synthetic material is engineered to deflect or stop sharp objects before they can reach the foot or the inner safety components.

A cut creates a direct path for nails, metal shards, or glass to penetrate the boot, immediately negating one of its core purposes.

The Hidden Dangers of Lost Waterproofing

Many work boots feature a waterproof membrane protected by the outer material. A cut exposes this delicate layer, almost guaranteeing its failure.

This leads to water absorption, which dramatically increases the boot's weight and causes fatigue. Constant moisture also creates an environment for fungal infections and can lead to dangerous losses of sensation in cold weather.

The Domino Effect of Structural Failure

The outer material provides the foundational structural integrity for the entire boot, supporting your ankle and foot. A cut is a point of weakness that expands with every step.

This weakness can lead to the sole delaminating, reduced ankle support, and an uneven walking platform, significantly increasing the risk of slips, trips, and falls.

When Safety Features Become Hazards

Ironically, damage to the outer material can turn the boot's own protective features into a source of danger by exposing them in ways they were not designed for.

Exposed Toe Caps

When a cut exposes a steel or composite toe cap, the boot is no longer safe. The exposed edge can become a serious snag hazard on machinery, ladders, or debris.

Furthermore, the initial impact that caused the cut may have also created micro-fractures in a composite toe or dented a steel toe, compromising its ability to withstand a future impact or compression event.

Breached Midsole Protection

Deep cuts can compromise the puncture-resistant plate located in the midsole. Once this layer is breached or exposed, the boot offers zero protection from sharp objects underfoot.

Common Pitfalls to Avoid

Understanding when a boot has reached the end of its service life is critical. Misjudging this can have severe consequences, and superficial fixes often create a false sense of security.

The False Economy of Repair

While minor scuffs can be treated, significant cuts cannot be reliably repaired to restore the boot's original safety rating. Glues and patches do not replicate the material strength or waterproofing of the original construction.

Relying on a patched boot for protection against punctures or impacts is a dangerous gamble.

Ignoring the Need for Inspection

The most common mistake is failing to perform regular inspections. A quick visual check at the start and end of each day is essential for identifying cuts, tears, or delamination before they lead to an incident.

Treat your boots like any other critical tool: inspect them before use to ensure they are fit for purpose.

Making the Right Choice: When to Replace

Your decision to replace your boots should be based on the specific hazards of your work environment.

- If your primary focus is protection from sharp objects: Any cut that visibly penetrates the outer material requires immediate replacement.

- If your primary focus is working in wet environments: Any damage that compromises the boot's waterproofing makes it unsuitable and unsafe for the job.

- If your primary focus is structural support and stability: Deep cuts, exposed safety features, or separation between the sole and the upper mean the boot's integrity has failed and it must be replaced.

Ultimately, your work boots are a non-negotiable tool for personal safety, and their condition must be treated with absolute seriousness.

Summary Table:

| Risk Category | Consequence | Key Takeaway |

|---|---|---|

| Loss of Protection | Direct path for punctures, loss of abrasion resistance | Any visible cut requires immediate replacement |

| Waterproofing Failure | Water absorption, increased weight, fungal infections | Damaged boots are unsafe for wet environments |

| Structural Failure | Reduced ankle support, sole delamination, increased fall risk | Deep cuts or separation mean the boot's integrity has failed |

| Exposed Safety Features | Toe caps become snag hazards; midsole protection is breached | Exposed components indicate critical failure |

Don't gamble with safety. Damaged boots are a liability.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the highest standards of durability and protection, guarding against the risks of cuts, wear, and failure.

Contact 3515 today to source reliable work boots that protect your team and your bottom line.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What safety features can some gumboots have? Essential PPE for Hazardous Work Environments