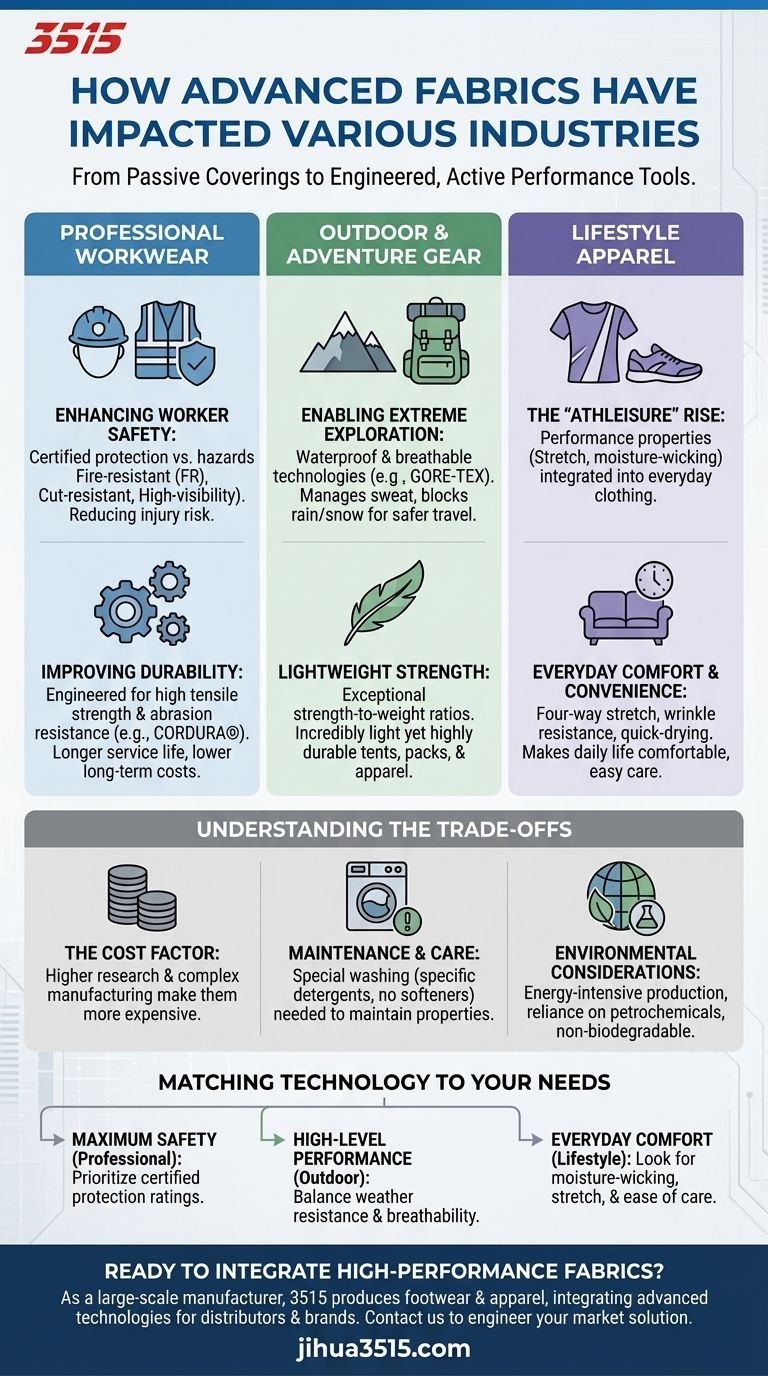

At their core, advanced fabrics have fundamentally transformed key industries by embedding high-performance characteristics directly into textiles. They have moved beyond simple clothing to become engineered materials that provide critical protection in professional workwear, enable new levels of performance in outdoor equipment, and bring enhanced comfort to everyday lifestyle apparel.

The true impact of advanced fabrics lies in their ability to solve specific, real-world problems. Instead of being passive coverings, these materials actively contribute to the user's safety, comfort, and performance in demanding environments.

The Core Innovation: From Thread to Technology

Traditional textiles are defined by their source material, like cotton or wool. Advanced fabrics, however, are defined by their engineered properties.

What Defines an "Advanced Fabric"?

An advanced fabric is a textile that has been engineered to achieve specific performance characteristics beyond the norm. This can include resistance to extreme temperatures, moisture, or physical abrasion.

These properties are often created through complex weaving techniques, chemical treatments, or the blending of synthetic fibers like aramid, nylon, and elastane.

From Passive Covering to Active Performance

Where a traditional cotton shirt simply covers the skin, an advanced fabric actively manages moisture by wicking it away. Where denim provides basic abrasion resistance, an aramid-fiber fabric can provide ballistic protection.

This shift turns apparel and equipment from passive items into active tools that enhance capability.

Impact on Professional Workwear

For frontline workers, the right fabric is not a matter of comfort but of safety and survival. This is where advanced textiles have made one of their most significant impacts.

Enhancing Worker Safety

Advanced fabrics offer certified protection against specific workplace hazards. This includes fire-resistant (FR) materials for firefighters, cut-resistant fabrics for industrial workers, and high-visibility textiles for construction crews.

These materials provide a critical layer of defense, directly reducing the risk of serious injury.

Improving Durability and Longevity

Workwear is subjected to extreme wear and tear. Fabrics engineered for high tensile strength and abrasion resistance, such as CORDURA®, last significantly longer than conventional alternatives.

This durability reduces long-term costs and ensures protective gear maintains its integrity over its service life.

Redefining Outdoor and Adventure Gear

The ability of adventurers to push boundaries is often directly linked to the performance of their equipment. Advanced fabrics are a cornerstone of modern outdoor gear.

Enabling Exploration in Extreme Conditions

Technologies like GORE-TEX create fabrics that are both waterproof and breathable. This allows moisture from sweat to escape while preventing rain and snow from getting in.

This single innovation has enabled safer and more comfortable exploration in harsh weather conditions, from mountaineering to trail running.

The Importance of Lightweight Strength

Every ounce matters when carrying gear over long distances. Advanced synthetic fibers provide exceptional strength-to-weight ratios, allowing for the creation of tents, backpacks, and apparel that are both incredibly light and highly durable.

Integrating Performance into Lifestyle Apparel

The properties once reserved for extreme applications have now made their way into the clothes we wear every day, creating a new standard for comfort and convenience.

The Rise of "Athleisure"

The athleisure trend is built on advanced fabrics. The stretch, moisture-wicking properties, and comfort of performance textiles are now expected in everyday clothing.

Everyday Comfort and Convenience

Features like four-way stretch, wrinkle resistance, and quick-drying capabilities have moved from the gym to the office. These fabric innovations make daily life more comfortable and clothing easier to care for.

Understanding the Trade-offs

While the benefits are clear, adopting advanced fabrics is not without its challenges. Objectivity requires acknowledging the downsides.

The Cost Factor

The research, development, and complex manufacturing processes make advanced fabrics significantly more expensive than conventional textiles. This cost is a primary barrier to wider adoption.

Maintenance and Care Requirements

Many high-performance fabrics require special care, such as washing with specific detergents or avoiding fabric softeners, to maintain their technical properties. Improper care can degrade performance over time.

Environmental Considerations

The production of many synthetic performance fibers is energy-intensive and reliant on petrochemicals. Furthermore, the durability that makes them valuable also means they do not biodegrade, posing an end-of-life challenge.

Matching Fabric Technology to Your Needs

The right choice depends entirely on your primary goal. Use the application to guide your decision.

- If your primary focus is maximum safety in a professional setting: Prioritize fabrics with certified protection ratings that directly address the specific hazards of your environment.

- If your primary focus is high-level performance in outdoor activities: Seek a balance of weather resistance (like waterproofing) and breathability to manage your body's microclimate.

- If your primary focus is everyday comfort and convenience: Look for features like moisture-wicking, multi-directional stretch, and ease of care to enhance daily wear.

Ultimately, advanced fabrics empower us by creating a seamless interface between our bodies and the environments we operate in.

Summary Table:

| Industry | Key Impact of Advanced Fabrics |

|---|---|

| Professional Workwear | Enhanced safety (FR, cut-resistant), improved durability, and reduced long-term costs. |

| Outdoor & Adventure Gear | Enables exploration in extreme conditions with waterproof/breathable materials and lightweight strength. |

| Lifestyle Apparel | Integrates performance features like moisture-wicking and stretch for everyday comfort and convenience. |

Ready to integrate high-performance fabrics into your product line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and apparel for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, integrating advanced fabric technologies for superior safety, durability, and comfort.

Contact us today to discuss how we can engineer the perfect solution for your market needs.

Visual Guide

Related Products

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- How does a retroreflectometer function in the performance evaluation of reflective materials? Ensure Safety Standards

- What are the primary manufacturing advantages of 3D printing for therapeutic insoles? Revolutionizing Custom Orthotics

- What are the advantages of laser welding for piezoelectric energy harvesters? Achieve Precision and Durability

- How does a three-axis magnetometer contribute to cooperative positioning? Accurate Heading in GNSS-Denied Zones

- What are some common issues that cause cold toes while cycling? Fix Your Cold Feet Problem Now

- What factors should riders consider when choosing between riding shoes and boots? Match Your Gear to Your Ride

- Why is heel movement in shoes problematic? A Guide to Preventing Blisters and Improving Stability

- Why is it important to wear the correct boots when riding a motorcycle? Essential Protection for Every Rider