For a definitive answer, steel toes provide superior long-term durability and resistance to cracking under repeated, heavy impacts. However, modern non-steel safety toes, such as composite or alloy, offer significantly better mobility and flexibility due to being 30-50% lighter while still meeting the same initial safety standards for impact and compression.

The choice between steel and non-steel safety toes is not about which is universally better, but about a critical trade-off. You are choosing between the absolute ruggedness of steel and the lightweight comfort and mobility of modern composite materials.

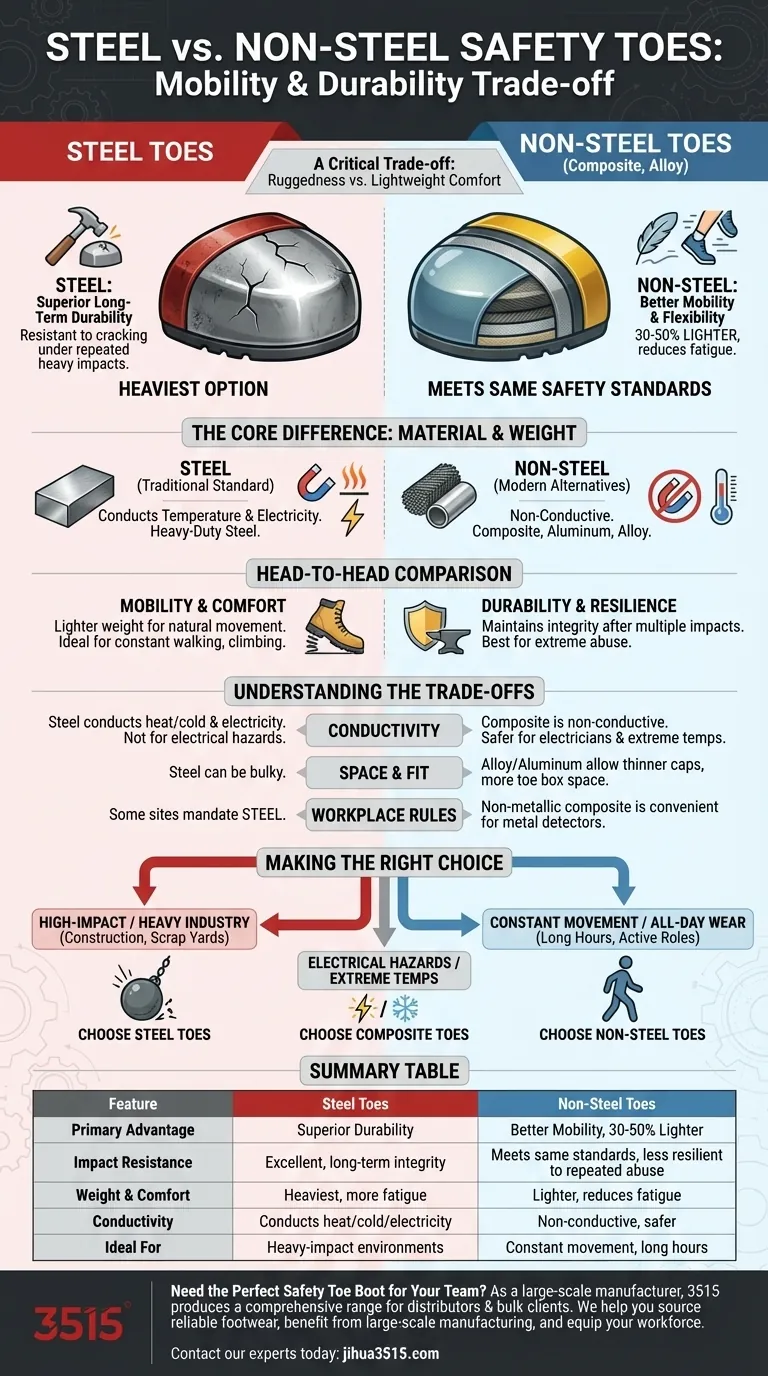

The Core Difference: Material and Weight

The fundamental distinction between safety toe types comes down to the material used in the protective cap. This single factor dictates weight, conductivity, and ultimately, comfort.

Steel Toes: The Traditional Standard

Steel toes are the original and most common form of safety footwear protection. They are made from heavy-duty steel, renowned for its strength and resilience.

This construction makes them exceptionally durable but also the heaviest option available.

Non-Steel Toes: The Modern Alternatives

"Safety toe" is a broad term that typically refers to non-metallic or lighter metal alternatives. The most common are composite, aluminum, and alloy toes.

These materials were engineered to provide protection comparable to steel but at a significantly lower weight, directly addressing the need for greater comfort and mobility.

A Head-to-Head Comparison: Mobility vs. Durability

Your daily experience in a work boot is defined by the balance between how it feels and how it protects. This is where the material differences become most apparent.

Mobility and All-Day Comfort

This is the primary advantage of non-steel toes. Being 30-50% lighter than steel, materials like composite and alloy drastically reduce foot fatigue over a long shift.

The lighter weight allows for more natural foot movement and flexibility, making them ideal for jobs that require constant walking, climbing, or crouching.

Impact Resistance and Long-Term Durability

Both steel and non-steel toes must meet the same ASTM safety standards for impact and compression resistance. A new composite boot will protect you from a major impact just as well as a new steel-toed boot.

The key difference lies in long-term wear and extreme abuse. Steel is more resistant to cracking and maintains its structural integrity better after suffering multiple significant impacts over time.

Understanding the Trade-offs

Choosing the right boot involves looking beyond the two primary factors of mobility and durability. Several secondary characteristics can be critical depending on your work environment.

Thermal and Electrical Conductivity

Steel is a metal and therefore conducts temperature and electricity. In very cold or hot environments, the toe cap can become uncomfortable. More importantly, it is not suitable for roles with significant electrical hazards.

Composite toes are non-metallic and do not conduct heat, cold, or electricity, making them the safest choice for electricians or those working in extreme weather conditions.

Space and Fit

Because alloy and aluminum can be made thinner than steel while providing the same strength, they can allow for a more spacious toe box without making the boot appear bulky.

This can lead to a more comfortable fit, especially for individuals with wider feet.

Workplace Requirements

Some job sites, particularly in heavy industry or construction, explicitly mandate steel toe boots as a safety requirement. Always verify your workplace rules first.

Conversely, for workers who frequently pass through metal detectors, non-metallic composite toes offer a significant convenience advantage.

Making the Right Choice for Your Job

Your final decision should be based on a clear understanding of your daily tasks and environment.

- If your primary focus is maximum durability in a high-impact environment (like heavy construction or scrap yards): Steel toes offer the most reliable long-term resilience against repeated abuse.

- If your primary focus is all-day mobility, comfort, and reduced fatigue (for roles requiring constant movement or long hours on your feet): Lighter alloy or composite toes are the superior choice.

- If you work in extreme temperatures or environments with electrical hazards: Non-conductive composite toes provide an essential layer of safety that metals cannot.

Ultimately, the best safety toe is the one that provides the necessary protection without compromising the comfort you need to perform your job effectively.

Summary Table:

| Feature | Steel Toes | Non-Steel Toes (Composite/Alloy) |

|---|---|---|

| Primary Advantage | Superior long-term durability | Better mobility & lighter weight (30-50% lighter) |

| Impact Resistance | Excellent, maintains integrity after repeated heavy impacts | Meets same ASTM standards, but less resilient to repeated abuse |

| Weight & Comfort | Heaviest option, can cause more fatigue | Lighter, reduces fatigue for all-day wear and movement |

| Thermal/Electrical Conductivity | Conducts heat, cold, and electricity | Non-conductive; safer for extreme temps and electrical work |

| Ideal For | Heavy-impact environments (construction, scrap yards) | Jobs requiring constant movement, climbing, or long hours on feet |

Need the Perfect Safety Toe Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, ensuring you get the right balance of protection, mobility, and durability for your specific needs.

We help you:

- Source reliable footwear that meets your exact safety and comfort requirements.

- Benefit from large-scale manufacturing efficiencies and consistent quality.

- Equip your workforce with boots that enhance safety and productivity.

Let's discuss your specific needs. Contact our experts today to find the ideal safety toe solution for your business.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How does composite toe compare to steel toe? Choose the Right Safety for Your Job

- What is the primary purpose of steel toe boots? Unmatched Protection for Your Workforce

- What is the primary purpose of steel toe cap safety boots? Ultimate Toe Protection for Hazardous Work

- What are the advantages of wearing steel-toe boots? Maximum Protection for Heavy-Duty Work

- What are the main drawbacks of traditional steel toed safety boots? Heavy Weight & Other Key Disadvantages

- Do moc toe boots have steel toe? Get Durable, Safety-Compliant Footwear

- What are steel toe boots and how are they designed? Essential Guide to Industrial Footwear Safety

- What are the advantages of steel toe shoes? Unmatched Protection for Industrial Work