Failing to wear appropriate steel toe shoes in high-risk workplaces exposes individuals and organizations to far more than just foot injuries. The consequences range from severe physical harm and fatalities to significant operational disruptions and financial liabilities for both the employee and the employer.

The decision to forgo required safety footwear is not a minor personal choice; it is a critical failure point that introduces cascading risks across an entire operation, affecting individual livelihoods, team productivity, and the company's bottom line.

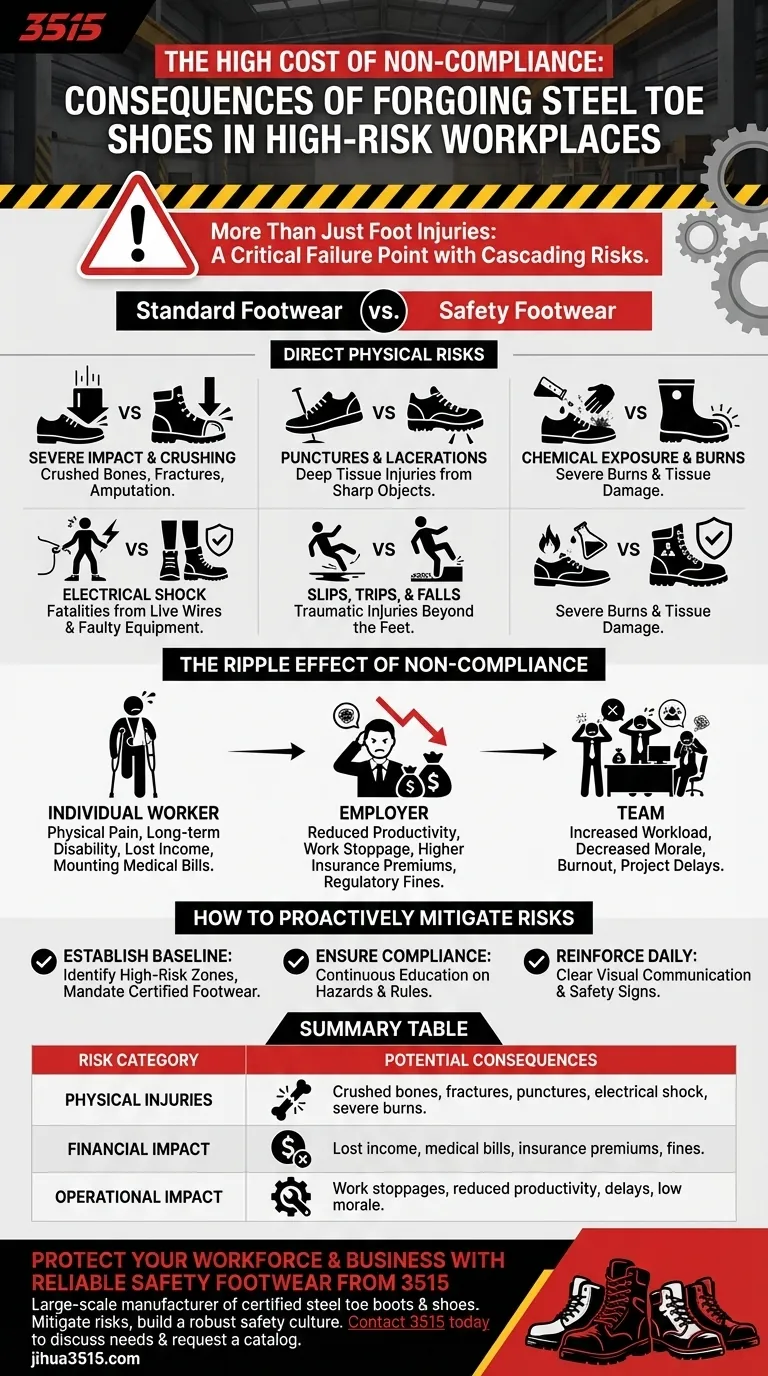

The Spectrum of Direct Physical Risks

The most immediate consequences of not wearing safety footwear are physical. Everyday shoes offer virtually no protection against the common hazards found in industrial, construction, or manufacturing environments.

Severe Impact and Crushing Injuries

Standard footwear provides no defense against falling objects or compression hazards. The result can be crushed bones, severe fractures, or even amputation, leading to permanent disability.

Punctures and Lacerations

Sharp objects like nails, scrap metal, or dropped tools can easily penetrate the sole or upper of a regular shoe. Steel toe boots are built with durable, puncture-resistant materials to prevent these deep tissue injuries.

Electrical Shock Hazards

Contact with live wires or faulty equipment can be fatal. Many steel toe boots are specifically designed with non-conductive materials to protect workers from electrical shocks, a feature entirely absent in standard shoes.

Slips, Trips, and Falls

High-risk environments often have wet, oily, or uneven surfaces. Safety footwear is engineered with specialized slip-resistant soles that provide superior traction, dramatically reducing the risk of falls that can cause injuries far beyond the feet.

Chemical Exposure and Burns

In facilities where chemicals or molten materials are handled, splashes can cause severe burns and tissue damage. Safety boots are made from materials designed to resist chemical permeation and high temperatures.

The Ripple Effect of Non-Compliance

An injury is never an isolated event. The consequences of non-compliance with safety footwear policies extend from the individual to the entire organization, creating significant and often unforeseen costs.

For the Individual Worker

The primary impact is physical pain and potential long-term disability. However, it also includes lost income during recovery, mounting medical bills, and a diminished capacity to work in the future.

For the Employer

For the business, a single incident leads to reduced productivity from a work stoppage and an absent employee. It also results in higher insurance premiums, potential regulatory fines, and the direct costs associated with accident investigation and cleanup.

For the Team

The absence of an injured team member places a greater workload on their colleagues, which can decrease morale and increase the risk of burnout. It disrupts workflow and can negatively impact project timelines.

How to Proactively Mitigate These Risks

A robust safety culture is not about reacting to incidents; it's about systematically preventing them. The responsibility falls on employers to create an environment where compliance is clear and consistent.

- If your primary focus is establishing a baseline of safety: Identify all high-risk zones and mandate certified protective footwear for anyone entering them.

- If your primary focus is ensuring compliance: Implement a strategy of continuous education for both managers and workers on the specific hazards and the reasons behind the rules.

- If your primary focus is reinforcing the policy daily: Use clear visual communication, such as prominent safety signs at all entrances, to make the PPE requirement impossible to ignore.

Ultimately, enforcing safety footwear standards is a fundamental act of protecting your most valuable asset—your people—and by extension, the stability of your entire operation.

Summary Table:

| Risk Category | Potential Consequences |

|---|---|

| Physical Injuries | Crushed bones, fractures, punctures, lacerations, electrical shock, severe burns. |

| Financial Impact | Lost income, high medical bills, increased insurance premiums, regulatory fines. |

| Operational Impact | Work stoppages, reduced productivity, project delays, low team morale. |

Protect your workforce and your business with reliable safety footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified steel toe boots and shoes designed to mitigate the severe risks outlined above. We supply distributors, brand owners, and bulk clients with durable footwear that meets the highest safety standards, helping you build a robust safety culture and avoid costly incidents.

Contact 3515 today to discuss your protective footwear needs and request a catalog of our products.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- What is the primary function of reinforced steel toe caps in industrial safety shoes? Protect Workers from Stone Impacts

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?

- Why is stabilization control essential for UHSS safety shoe toe caps? Key Factors for High-Strength Protection

- What is the purpose of front hardeners in safety shoes? Essential Protection for Construction & Welding