First, I need to understand what the user truly wants. They're not just asking about how to clean PVC boots; they're trying to figure out if PVC is the right choice for their specific job. "Easy maintenance" is a surface-level question, and the real core is "what are the implications of choosing PVC?". So, I need to analyze the references critically, synthesize the information, and stay focused on the user's needs to create the definitive guide they expect.

The user, as an intelligent professional, needs clarity. My tone should be objective, authoritative, and empathetic. This article will be radically scannable with clear headings, short paragraphs, and a key takeaway box.

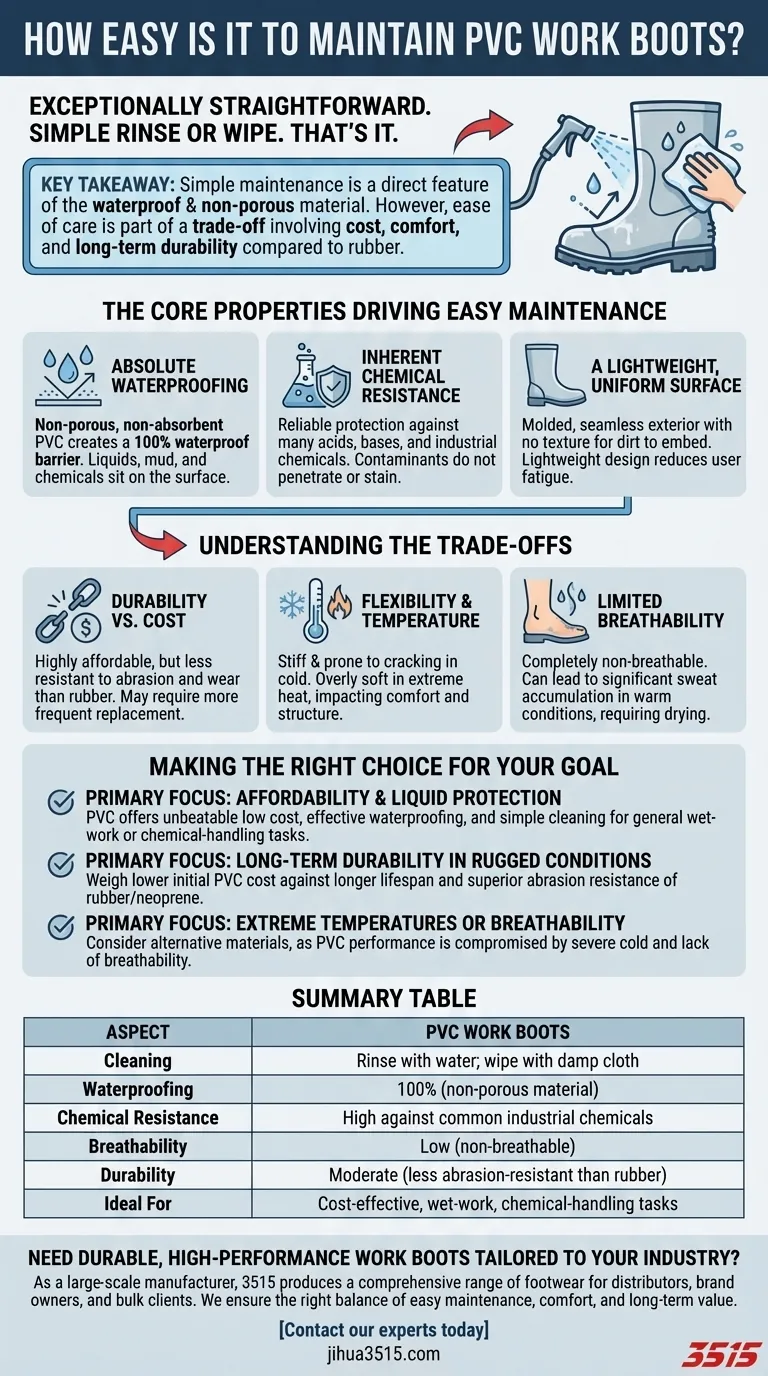

I'll start with a bold opening hook directly addressing the maintenance question, saying that PVC boots are exceptionally easy to clean. You can simply rinse them with water or wipe them down. The key is their non-absorbent nature. I will follow with a core takeaway box that encapsulates the broader picture.

The main body will then delve into the “why” - why choose PVC in the first place? I'll cover the core properties: absolute waterproofing (it's non-porous), inherent chemical resistance, and the lightweight design, which reduces user fatigue.

Then, the critical part: the trade-offs. I'll be clear about the compromises. While PVC is cheaper, it doesn't last as long as rubber. I'll also add that, while soft and comfortable, they are not breathable. This will cause discomfort in hot conditions, creating a whole new kind of "maintenance" challenge. Furthermore, the material can become stiff in cold environments. These insights go beyond the given references but are well-known properties of the material.

Finally, I'll conclude with actionable advice. Bullet points will clarify: if your focus is cost-effectiveness and liquid protection, PVC is the go-to. If you need longevity, rubber or neoprene might be better. In extreme temperatures, or where breathability is vital, other materials are preferable.

The closing will be an empowering sentence: Understanding these characteristics lets you choose boots based on overall performance, not just maintenance. From a maintenance perspective, PVC work boots are exceptionally straightforward. Their non-absorbent material means cleaning is a simple matter of rinsing with water or wiping them down with a damp cloth. This efficiency is a direct result of PVC's inherent properties, making daily upkeep minimal.

The simplicity of maintaining PVC boots is a direct feature of the material's waterproof and non-porous nature. However, this ease of care is part of a larger equation involving a distinct trade-off between cost, comfort, and long-term durability when compared to materials like rubber.

The Core Properties Driving Easy Maintenance

To understand why PVC boots are so easy to care for, you must first understand the material itself. The maintenance is not a separate feature but a direct outcome of its fundamental characteristics.

Absolute Waterproofing

PVC (Polyvinyl Chloride) is a synthetic plastic polymer. By its very nature, it is non-porous and non-absorbent, creating a 100% waterproof barrier.

Unlike leather or other materials, liquids, mud, and chemicals sit on the surface without being absorbed. This is the primary reason a simple rinse is usually all that is required for cleaning.

Inherent Chemical Resistance

PVC offers reliable protection against a wide range of common acids, bases, and industrial chemicals.

This resistance means that contaminants not only fail to penetrate the boot but also don't cause the material to break down or stain upon immediate contact, further simplifying the cleaning process.

A Lightweight, Uniform Surface

PVC boots are manufactured in a molding process that creates a seamless, smooth exterior.

This lack of seams or texture leaves no place for dirt and grime to become deeply embedded, contributing significantly to how quickly and effectively they can be cleaned. Their lightweight nature also reduces fatigue during a long workday.

Understanding the Trade-offs

While the maintenance is simple, selecting PVC boots involves accepting a specific set of compromises. Acknowledging these trade-offs is critical for making an informed decision.

Durability vs. Cost

The primary trade-off is durability. PVC is highly affordable but is generally less resistant to abrasion, punctures, and daily wear-and-tear than premium rubber boots.

While you save on the initial purchase, PVC boots may need to be replaced more frequently, especially in physically demanding environments.

Flexibility and Temperature

PVC's flexibility is temperature-dependent. In very cold conditions, the material can become stiff and more prone to cracking.

Conversely, in extreme heat, it can become overly soft. This can impact both comfort and the boot's structural integrity over time.

Limited Breathability

The same non-porous quality that makes PVC waterproof also makes it completely non-breathable.

In warm conditions or during strenuous activity, this can lead to significant sweat accumulation inside the boot, which can cause discomfort. This internal moisture requires its own form of "maintenance" in the form of proper drying between uses.

Making the Right Choice for Your Goal

Your decision should be based on the specific demands of your work environment, not just one feature like maintenance.

- If your primary focus is affordability and protection from liquids: PVC boots offer an unbeatable combination of low cost, effective waterproofing, and simple cleaning for general wet-work or chemical-handling tasks.

- If your primary focus is long-term durability in rugged conditions: You should weigh the lower initial cost of PVC against the potentially longer lifespan and superior abrasion resistance of a rubber or neoprene boot.

- If you work in extreme temperatures or require breathability: Consider alternative materials, as PVC's performance can be compromised by severe cold and its non-breathable nature is a significant drawback for comfort in the heat.

Ultimately, understanding these core characteristics allows you to choose a boot based not just on its maintenance, but on its total performance for your specific needs.

Summary Table:

| Aspect | PVC Work Boots |

|---|---|

| Cleaning | Rinse with water; wipe with damp cloth |

| Waterproofing | 100% (non-porous material) |

| Chemical Resistance | High against common industrial chemicals |

| Breathability | Low (non-breathable) |

| Durability | Moderate (less abrasion-resistant than rubber) |

| Ideal For | Cost-effective, wet-work, chemical-handling tasks |

Need durable, high-performance work boots tailored to your industry? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and industrial shoes and boots, ensuring you get the right balance of easy maintenance, comfort, and long-term value. Contact our experts today to discuss your specific requirements and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What activities are packer boots suitable for? The Ultimate Hybrid Boot for Riding and Work

- Why is high-strength industrial sewing equipment indispensable in heavy-duty work boots? Ensure Structural Integrity

- How do engineer boots function compared to other types of boots? A Guide to Their Unique Design & Purpose

- What factors should firefighters consider when choosing footwear? A Guide to Safety & Fit

- How long should you wait before wearing boots after waterproofing? Ensure Maximum Durability

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- Why is breathability important in winter boots? Keep Your Feet Dry and Warm

- How should work boots be stored? Protect Your Investment with Proper Storage