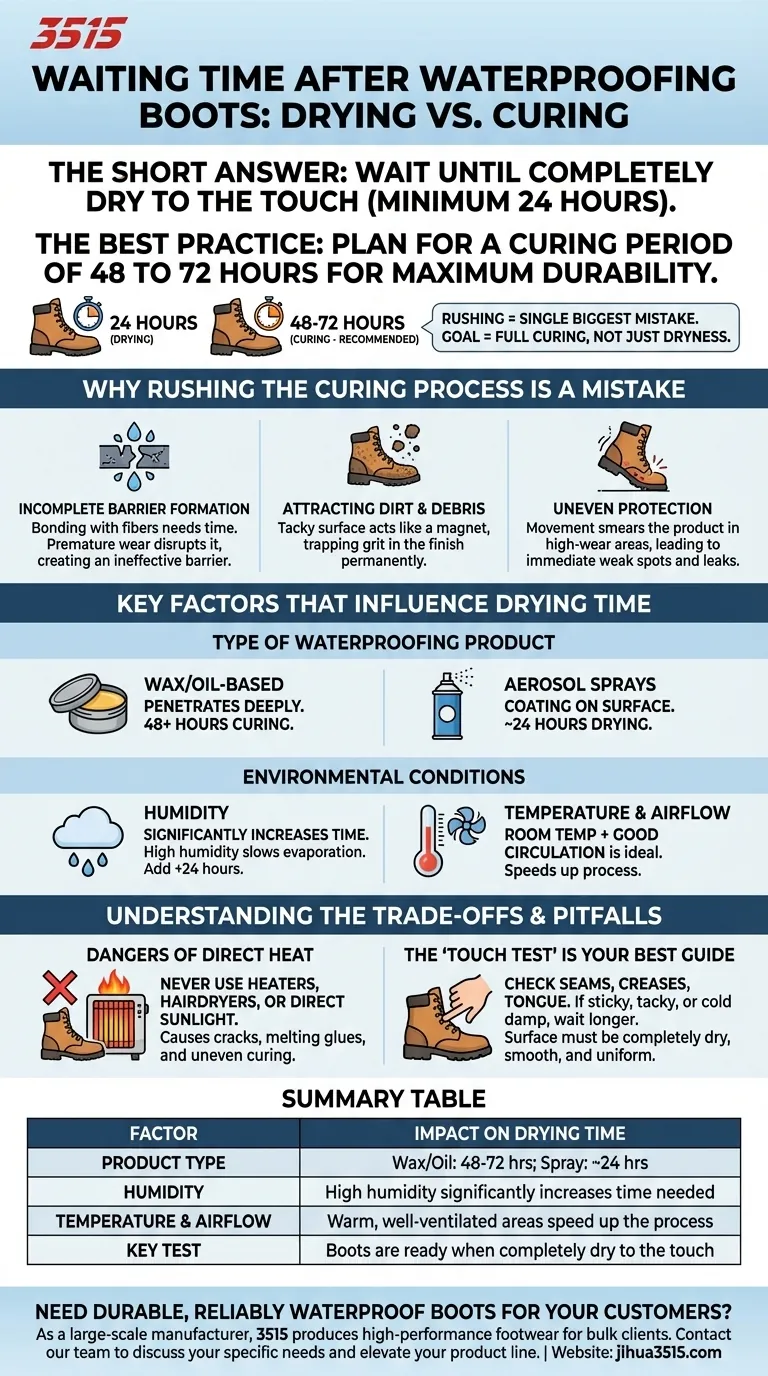

The short answer is you should wait until the boots are completely dry to the touch before wearing them. While this can happen in as little as 24 hours, it's often best to plan for a curing period of 48 to 72 hours to ensure the waterproofing treatment has fully bonded with the material.

Rushing the drying process is the single biggest mistake you can make after treating your boots. The goal isn't just dryness, but full curing—allowing the protective barrier to properly set and achieve maximum durability.

Why Rushing the Curing Process Is a Mistake

Applying a waterproofing treatment is only half the battle. The drying and curing phase is what determines whether that treatment will succeed or fail when you need it most.

Incomplete Barrier Formation

Waterproofing agents work by bonding with the fibers of your boot's material, whether it's leather or a synthetic fabric. This chemical process requires time. Wearing boots prematurely can disrupt this bonding, leaving you with an incomplete and ineffective waterproof barrier.

Attracting Dirt and Debris

A partially cured treatment, especially a wax or oil-based one, will have a tacky or sticky surface. Wearing boots in this state turns them into a magnet for dust, dirt, and grit, which can get permanently trapped in the finish and compromise its integrity.

Uneven Protection

Walking in freshly treated boots causes the material to flex, stretch, and rub. This movement can smear the product and rub it off in high-wear areas like the crease of the toe box, resulting in weak spots that will leak almost immediately.

Key Factors That Influence Drying Time

There is no single magic number for drying time because it depends entirely on the product, the boot, and the environment.

The Type of Waterproofing Product

Wax or oil-based treatments are designed to penetrate deeply into leather pores. Because they are absorbed into the material, they naturally require a longer curing time, often 48 hours or more.

Aerosol sprays (often silicone or acrylic-based) create a coating that sits more on the surface. These tend to dry much faster, with many being ready within 24 hours.

Environmental Conditions

Humidity is the most significant factor. High humidity slows down evaporation, dramatically increasing the necessary drying time. A treatment that cures in 24 hours in a dry climate might take 72 hours in a humid one.

Temperature and airflow also play a role. A room-temperature space with good air circulation is ideal for promoting evaporation and proper curing.

Understanding the Trade-offs and Pitfalls

Patience is crucial, but so is using the right method. Many well-intentioned shortcuts can permanently damage your boots.

The Dangers of Direct Heat

Never try to speed up the process with a direct heat source. Using a hairdryer, placing boots near a radiator, or leaving them in direct sunlight can cause catastrophic damage.

Heat can crack and dry out leather, melt the glues that hold the sole together, and cause the waterproofing agent to cure unevenly or not at all.

The "Touch Test" Is Your Best Guide

The most reliable way to know if your boots are ready is the simple touch test. Lightly touch several areas of the boot, paying special attention to seams, creases, and the tongue.

If you feel any tackiness, stickiness, or cold dampness, they are not ready. The surface should feel completely dry, smooth, and uniform.

Making the Right Choice for Your Boots

Use your product and environment to set a realistic timeline.

- If you used a heavy wax or grease-based product: Plan for a longer curing period of 48-72 hours and check for an even, non-tacky finish.

- If you used a lighter spray-on treatment: Expect a faster turnaround of around 24 hours, but always confirm with the touch test.

- If your environment is humid or cold: Be prepared to add at least another 24 hours to your estimated drying time and maximize air circulation if possible.

Ultimately, patience in the drying process is the final, critical step to ensuring your boots perform when you need them most.

Summary Table:

| Factor | Impact on Drying Time |

|---|---|

| Product Type | Wax/Oil: 48-72 hours; Spray: ~24 hours |

| Humidity | High humidity significantly increases time needed |

| Temperature & Airflow | Warm, well-ventilated areas speed up the process |

| Key Test | Boots are ready when completely dry to the touch |

Need durable, reliably waterproof boots for your customers? As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the highest standards for quality and protection. Contact our team today to discuss your specific needs and elevate your product line.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health