The most critical factors for choosing firefighter footwear are compliance with safety standards, the specific types of protection offered, and a precise, comfortable fit for your individual needs and work environment. These elements work together to ensure your safety, reduce fatigue, and maintain your effectiveness during demanding incidents.

Choosing the right firefighter boot is not about finding the "best" boot overall, but about finding the optimal balance of material, fit, and protective features that directly addresses the specific hazards you face most often.

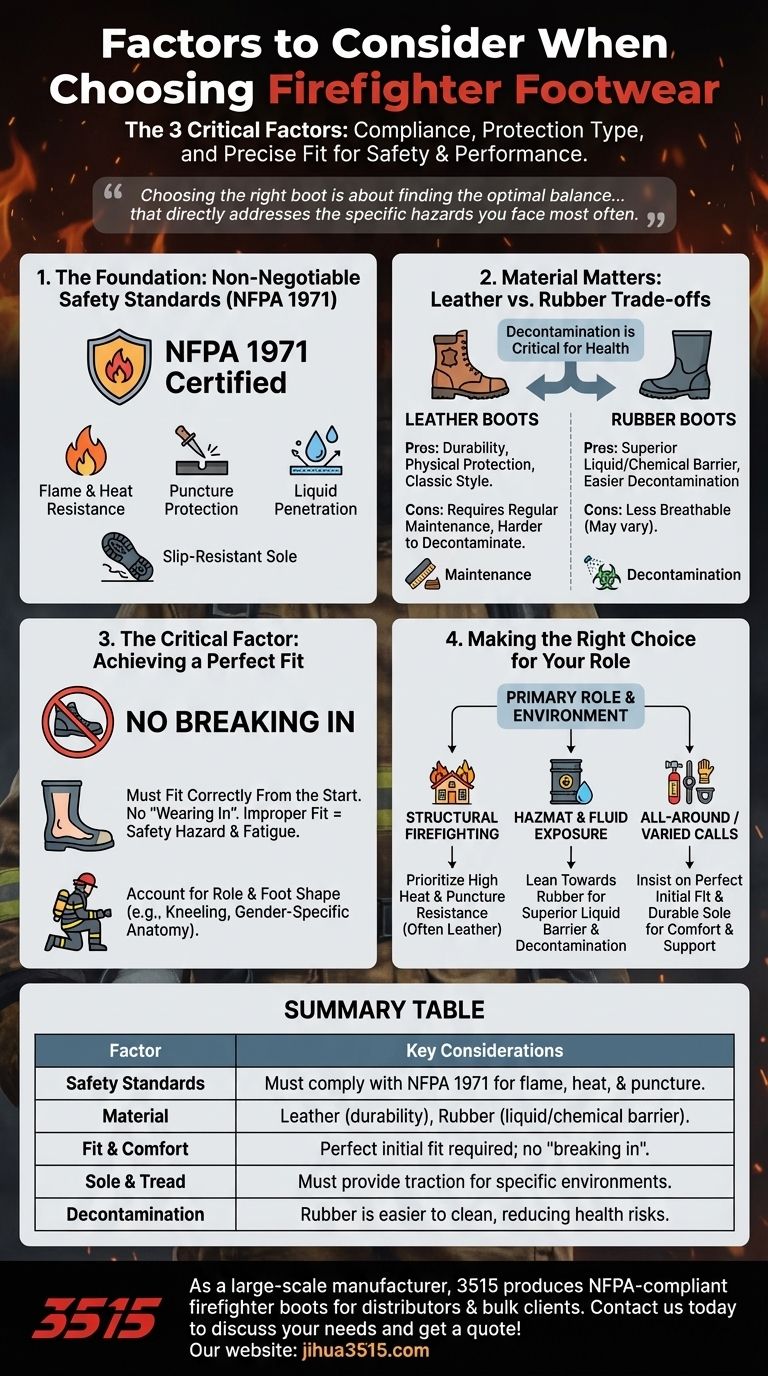

The Foundation: Non-Negotiable Safety Standards

Before considering any other feature, you must confirm that a boot meets the established safety regulations for your jurisdiction. This is the baseline for ensuring the footwear can withstand the rigors of the job.

Adhering to NFPA Standards

All structural firefighting boots must comply with standards like the National Fire Protection Association (NFPA) 1971. This certification ensures the boot has been rigorously tested for performance in flame, heat, puncture, and liquid penetration.

Understanding Key Protective Ratings

NFPA certification covers multiple areas of protection. Look for specific capabilities that protect against high heat, punctures from below, cuts, and abrasions. The standard also mandates slip-resistant soles to prevent falls on wet or uneven surfaces.

Beyond the Label: Assessing Real-World Protection

While standards provide a baseline, the construction and materials of a boot determine its performance and longevity in the field.

Material Matters: Leather vs. Rubber

The choice between leather and rubber is a primary consideration. Leather boots are known for durability and a classic style, offering excellent protection against physical hazards. Rubber boots provide a superior barrier against water, chemicals, and other liquid contaminants.

The Importance of Decontamination

Your work exposes you to numerous contaminants, including fuel and blood. These substances can penetrate leather, especially if it's scuffed or worn. Rubber boots are significantly easier to decontaminate, a critical factor for mitigating long-term health risks.

Sole and Tread for Your Environment

The boot's sole is your direct interface with hazardous terrain. Consider the environments you work in most, whether they are hard concrete, wet and muddy ground, or debris-strewn structures. The sole must provide appropriate traction and support for those specific conditions.

Understanding the Trade-offs

No single boot is perfect for every scenario. Understanding the inherent trade-offs between different styles is key to making an informed decision.

The Durability of Leather

Leather boots often offer a robust, long-lasting solution with proper care. Many firefighters prefer the feel and support of a well-maintained leather boot. However, they require regular cleaning and conditioning to maintain their protective qualities and extend their lifespan.

The Practicality of Rubber

Rubber boots excel in wet conditions and hazardous material responses. Their primary advantage is the ease with which they can be cleaned and decontaminated, protecting you from chemical and biological exposures long after the call is over.

The Role of Regular Maintenance

Regardless of material, proper care is essential. Regularly cleaning, drying, and (for leather) conditioning your boots ensures they remain durable and continue to provide the necessary support and protection you rely on.

The Critical Factor: Achieving a Perfect Fit

An ill-fitting boot is more than an inconvenience; it's a safety hazard that can cause fatigue, affect your gait, and lead to injury.

Why "Breaking In" Is a Myth

Unlike casual shoes, safety boots do not "wear in" over time. Their protective structures are rigid by design. A boot must fit correctly from the moment you put it on. An improper fit can cause stress on the shoe's structure and compromise its integrity.

Accounting for Your Feet and Role

The boot must suit your foot shape and your specific job requirements. If your work involves frequent kneeling, ensure the toecap design doesn't cause discomfort. Both men and women should seek boots designed for their distinct foot anatomy to ensure proper support and comfort.

Making the Right Choice for Your Role

Ultimately, your boot choice should be guided by the primary demands of your specific role and environment.

- If your primary focus is structural firefighting: Prioritize boots with the highest heat and puncture resistance ratings, often found in traditional leather models.

- If your role involves frequent HAZMAT or exposure to fluids: Lean towards rubber boots for their superior liquid barrier and ease of decontamination.

- If you need an all-around boot for varied calls: Insist on a perfect initial fit and a durable sole, as comfort and support are critical for reducing fatigue across long incidents.

Investing the time to select the right footwear is a direct investment in your long-term safety, health, and effectiveness on the job.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Safety Standards | Must comply with NFPA 1971 for flame, heat, and puncture resistance. |

| Material | Leather for durability; Rubber for superior liquid/chemical barrier. |

| Fit & Comfort | Requires a perfect fit from the start; no "breaking in" period. |

| Sole & Tread | Must provide traction for specific environments (e.g., wet, debris). |

| Decontamination | Rubber boots are easier to clean, reducing long-term health risks. |

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-compliant firefighter boots for distributors, brand owners, and bulk clients. Whether you need durable leather boots for structural firefighting or practical rubber boots for HAZMAT response, our production capabilities ensure the perfect balance of safety, comfort, and performance for your team. Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the main factors to consider when selecting work boots? A Guide to Safety, Comfort & Durability

- What are the best practices for storing leather work boots? Preserve Your Investment for Years

- What are the common hazards that safety work boots protect against? Essential Protection for Your Job Site

- What certification standard do all work boots meet? Your Guide to ASTM F2413 & Beyond

- What are the risks of not wearing proper work-safe boots? Avoid Costly Injuries & Downtime

- What are the limitations of pull-on work boots? A Guide to Choosing for Safety & Support

- How has work boot design evolved over time? From Simple Protection to Engineered Performance

- What are the main benefits of composite toe work boots? Lighter, Safer, and More Comfortable