In short, a composite toe boot is chosen over a steel toe for its lighter weight, superior insulation in extreme temperatures, and because it is non-metallic. These features provide significant advantages in comfort and safety for specific work environments, all while meeting the same official safety standards as traditional steel toes.

While both steel and composite toe boots are engineered to pass the same ASTM safety-impact standards, the decision between them is not about which is "safer." It's about selecting the right tool for the job based on your specific workplace conditions and personal comfort.

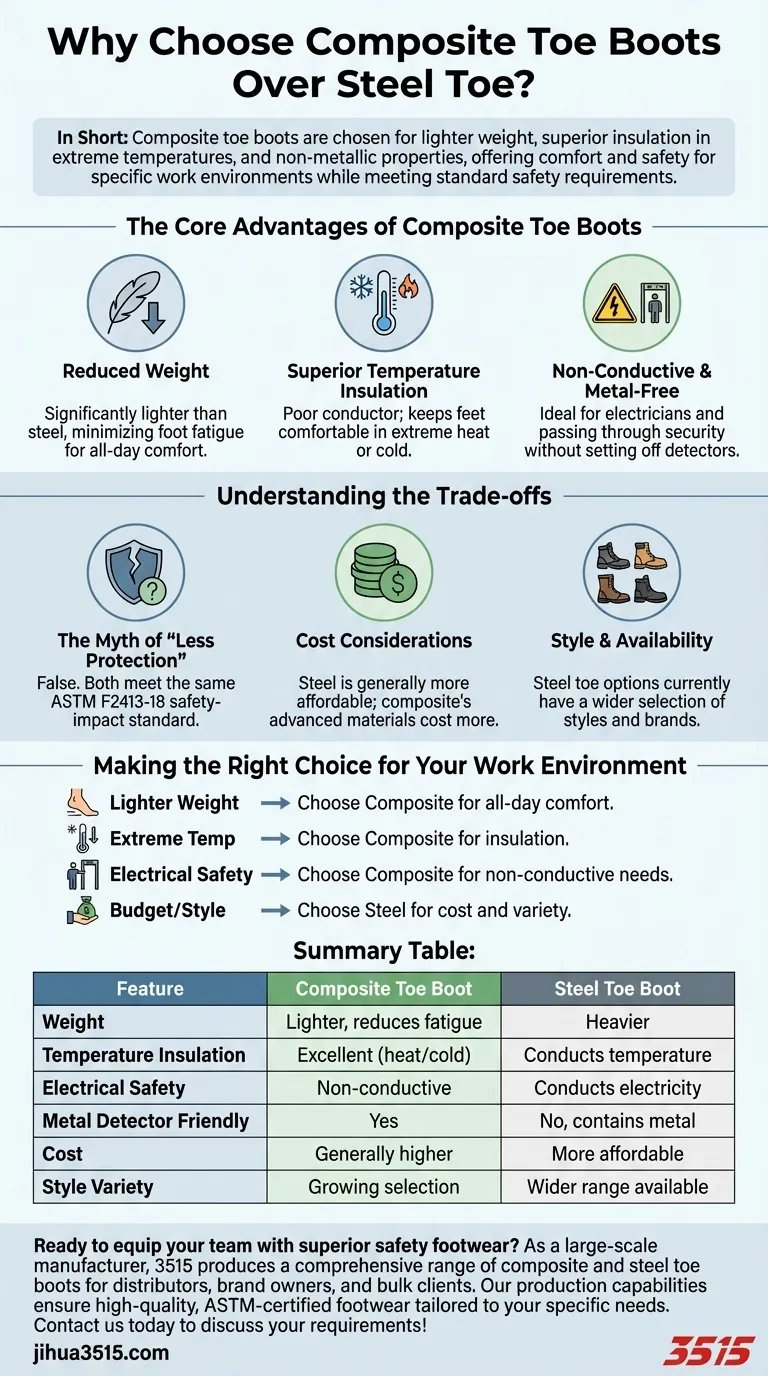

The Core Advantages of Composite Toe Boots

Composite toe caps are constructed from non-metallic materials like Kevlar, carbon fiber, or plastic. This fundamental difference from steel is what creates their unique set of benefits for the wearer.

Reduced Weight for All-Day Comfort

The most immediate benefit of a composite toe is its significantly lighter weight compared to steel.

While it may seem like a minor difference, this reduction in weight minimizes foot fatigue over a long workday, leading to greater overall comfort and less strain on your body.

Superior Temperature Insulation

Unlike metal, the materials used in composite toes are poor conductors of energy.

This means they do not transfer cold or heat as easily as steel. In extreme cold or hot environments, your feet will remain more comfortable and better protected from the ambient temperature.

Non-Conductive and Metal-Free Properties

Being entirely free of metal is a critical safety feature for certain professions.

These boots are ideal for electricians or anyone working in environments where electrical hazards are a concern. They also won't set off metal detectors, which is a valuable convenience for workers who must pass through security checkpoints regularly.

Understanding the Trade-offs

Choosing composite toe boots is not without its considerations. An objective evaluation requires looking at the potential downsides compared to their steel counterparts.

The Myth of "Less Protection"

It is a common misconception that composite toes are less protective. Both composite and steel toe boots must meet the same ASTM F2413-18 standard for impact and compression resistance. One is not inherently "safer" than the other in a test scenario.

Cost Considerations

Generally, steel toe boots are less expensive. The advanced materials and manufacturing processes required for composite toes often result in a higher price point.

Style and Availability

The steel toe boot has been the industry standard for decades, and as a result, it is available in a wider variety of styles and brands. While composite options are growing, steel still dominates the market in terms of sheer selection.

Making the Right Choice for Your Work Environment

Your final decision should be guided by the unique demands of your job and your personal priorities.

- If your primary focus is all-day comfort and reducing fatigue: Choose composite toe boots for their lighter weight.

- If your primary focus is working in extreme heat or cold: Choose composite toe boots for their superior temperature insulation.

- If your primary focus is electrical safety or passing through metal detectors: Choose composite toe boots as they are non-metallic and non-conductive.

- If your primary focus is budget or having the widest selection of styles: Choose steel toe boots for their lower cost and market variety.

Ultimately, understanding these key differences empowers you to select the safety footwear that best serves your specific needs.

Summary Table:

| Feature | Composite Toe Boot | Steel Toe Boot |

|---|---|---|

| Weight | Lighter, reduces fatigue | Heavier |

| Temperature Insulation | Excellent in extreme heat/cold | Conducts temperature |

| Electrical Safety | Non-conductive, ideal for electricians | Conducts electricity |

| Metal Detector Friendly | Yes, passes through easily | No, contains metal |

| Cost | Generally higher | More affordable |

| Style Variety | Growing selection | Wider range available |

Ready to equip your team with superior safety footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of composite and steel toe boots for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, ASTM-certified footwear tailored to your specific work environment needs. Contact us today to discuss your requirements and benefit from our expertise in safety footwear manufacturing!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites