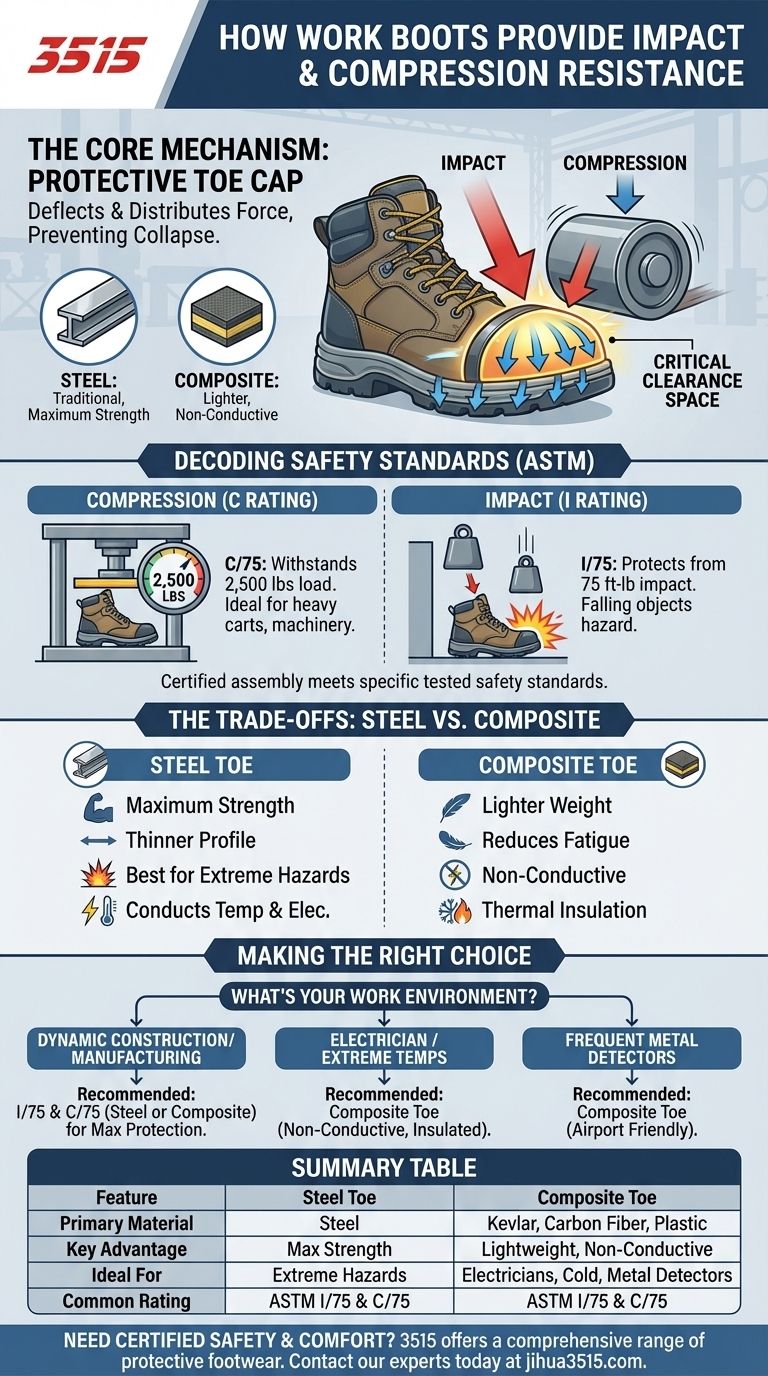

At their core, work boots provide impact and compression resistance through a reinforced protective toe cap. This structural shield, typically made of steel or composite materials, is engineered to withstand a significant amount of force from a falling object (impact) or a heavy rolling or static load (compression), preventing the toe box from crushing and protecting your feet.

The key takeaway is that true protection isn't just about having a "steel toe." It's about the entire toe cap assembly meeting specific, tested safety standards, such as the ASTM C/75 rating, which guarantees resistance to a compressive force of 2,500 pounds.

The Core Mechanism: The Protective Toe Cap

A work boot's safety features are centered around the design and material of its integrated toe cap. This is the primary component responsible for resisting crushing forces.

How It Works

The protective toe cap is a rigid, dome-shaped shield built into the front of the boot. Its purpose is to deflect and distribute the force of an impact or a compressive load away from your toes and across the stronger structure of the boot's sole.

This prevents the toe area from collapsing under pressure, maintaining a critical space of clearance and preventing severe injury.

Common Materials Used

Steel has long been the traditional material for safety toes due to its exceptional strength and durability. It provides a proven and reliable defense against both impact and compression.

Composite materials are a modern alternative. These non-metallic toe caps (made from materials like Kevlar, carbon fiber, or plastic) offer similar compression resistance to steel while being lighter and not conducting heat, cold, or electricity.

Decoding the Safety Standards

The terms "impact resistant" and "compression resistant" are not subjective. They correspond to specific performance standards regulated by organizations like ASTM International (formerly American Society for Testing and Materials).

Understanding Compression Ratings

A boot's resistance to crushing from a slow, heavy load is its compression rating. This is a critical factor in environments where feet could be run over by heavy carts, machinery, or have heavy items dropped on them.

The ASTM standard uses a "C" rating. The highest and most common rating is C/75, which signifies the toe cap can withstand a compressive load of 2,500 pounds before the toe box significantly deforms.

Understanding Impact Ratings

Impact ratings measure the boot's ability to protect against something heavy falling onto it from a height. This is a separate but equally important test.

An I/75 rating, for example, means the boot provides protection from a 75 foot-pound impact. Both I/75 and C/75 ratings are often found together and represent the highest level of protection for most work environments.

The Trade-offs: Steel vs. Composite

While both steel and composite toe caps can meet the same C/75 safety standard, they have different properties that make them suitable for different jobs.

The Case for Steel Toes

Steel is the benchmark for strength and is often slightly thinner than a composite cap offering the same protection. It provides maximum, time-tested security in environments with extreme crushing or impact hazards.

The Benefits of Composite Toes

Composite toes are significantly lighter, reducing foot fatigue over a long day. Because they are non-metallic, they do not conduct electricity, making them ideal for electricians. They also don't transfer cold as easily in refrigerated environments.

Making the Right Choice for Your Goal

Your work environment dictates the type and level of protection you need.

- If your primary focus is maximum protection in a dynamic construction or manufacturing environment: A boot with an I/75 and C/75 rating, whether steel or composite, is the recommended standard.

- If you are an electrician or work in extreme temperatures: A composite toe boot offers the necessary C/75 protection without the risks of electrical conductivity or thermal transfer.

- If you need to pass through metal detectors frequently: A composite toe boot will save you time and hassle while still providing certified protection.

Ultimately, choosing the right boot means matching its certified safety ratings to the specific hazards of your job.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Primary Material | Steel | Kevlar, Carbon Fiber, Plastic |

| Key Advantage | Maximum, time-tested strength | Lighter weight, non-conductive |

| Ideal For | Extreme crushing/impact hazards (e.g., construction) | Electricians, cold environments, metal detectors |

| Common Safety Rating | ASTM I/75 & C/75 | ASTM I/75 & C/75 |

Need work boots that guarantee safety and comfort?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether you need the maximum protection of steel toes or the lightweight, non-conductive benefits of composite materials, our production capabilities ensure your team gets the right boots for the job.

Contact our experts today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the key features for work boots for roofers? Prioritize Grip, Stability, and Safety

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- What is Goodyear Welt Construction and its origin? The Gold Standard for Durable Footwear

- What types of electrical hazard protection are available in work boots? EH vs. SD Safety Explained

- What is the primary function of specialized rubber safety boots in high-risk autopsies? Ensure Viral Fluid Containment

- What are the common types of women's work boots? Find the Right Boot for Your Job's Hazards

- In what work environments are soft-toe boots most suitable? Prioritize Comfort and Agility for Light-Duty Work

- How do insulated boots help with moisture control? Keep Your Feet Warm and Dry