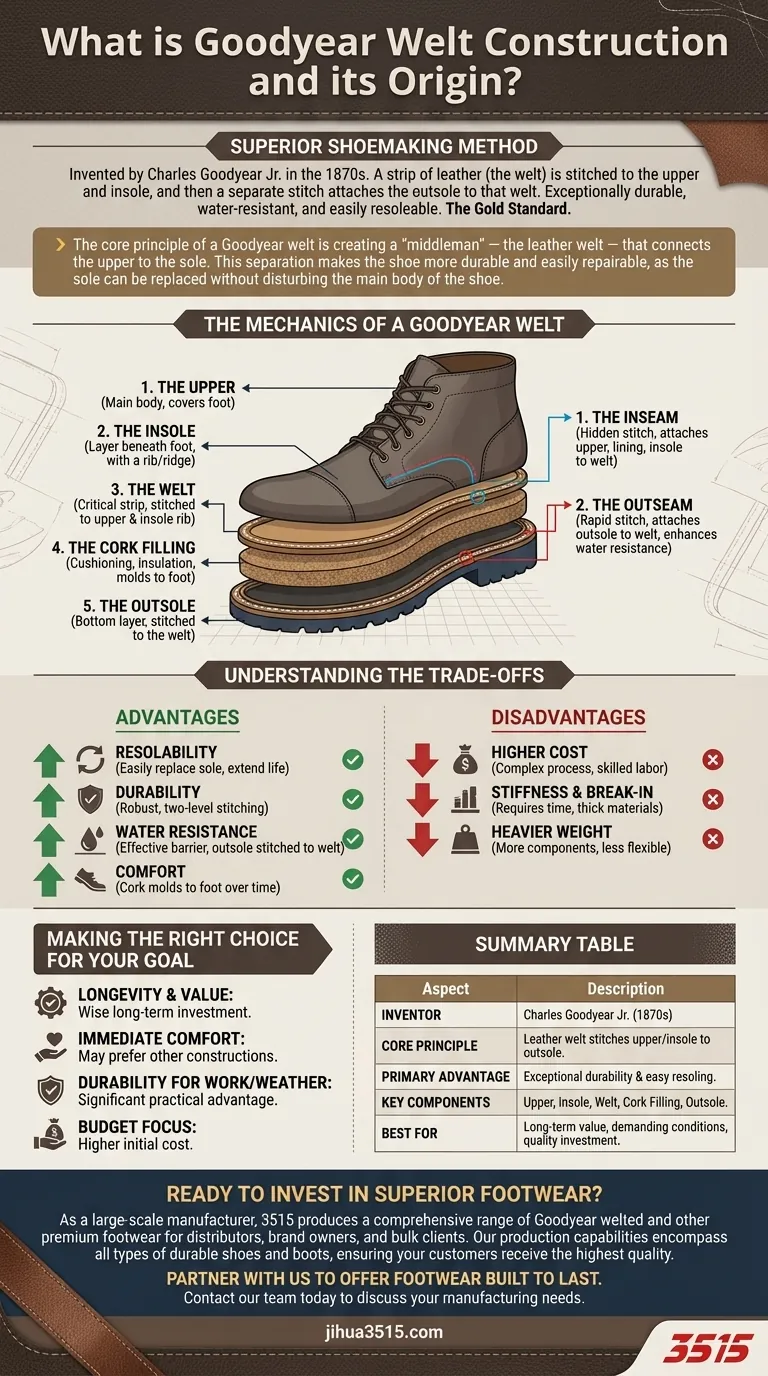

In short, Goodyear Welt Construction is a superior method of shoemaking where a strip of leather (the welt) is stitched to the upper and insole of a shoe, and then a separate stitch attaches the outsole to that welt. Invented by Charles Goodyear Jr. in the 19th century, this technique creates an exceptionally durable, water-resistant, and easily resoleable shoe, which is why it is often considered the gold standard for quality footwear.

The core principle of a Goodyear welt is creating a "middleman" — the leather welt — that connects the upper to the sole. This separation makes the shoe more durable and easily repairable, as the sole can be replaced without disturbing the main body of the shoe.

The Mechanics of a Goodyear Welt

A common misconception is that this method is directly related to the Goodyear Tire & Rubber Company. In fact, it was invented by Charles Goodyear Jr., son of the man who invented vulcanized rubber. He patented the machinery that could perform this complex stitching process in the 1870s, revolutionizing what was once a painstaking, hand-sewn craft.

The Key Components

The process involves several distinct parts coming together.

- The Upper: This is the main body of the shoe that covers your foot.

- The Insole: The layer directly beneath your foot. In a Goodyear welt, a "rib" or ridge is created on the insole to serve as an anchor point.

- The Welt: This is the critical component—a strip of leather stitched around the perimeter of the shoe. It attaches to both the upper and the insole's rib.

- The Cork Filling: The cavity created between the insole and the outsole is filled with a layer of cork. This provides cushioning, insulation, and will mold to the shape of your foot over time.

- The Outsole: The final, bottom layer that contacts the ground. It is stitched directly to the welt, not to the upper.

The Two-Stitch System

The magic of the Goodyear welt lies in its two independent stitches.

- The Inseam: This first stitch is hidden. It runs through the upper, the lining, and the insole rib, attaching them all to the welt.

- The Outseam (or Rapid Stitch): This second, visible stitch runs through the welt and attaches the outsole. Because this stitch doesn't penetrate the insole, it significantly enhances water resistance.

Understanding the Trade-offs

While considered a premium construction method, the Goodyear welt is not without its compromises. Understanding these is key to knowing if it's right for you.

The Advantages

- Resolability: This is the primary benefit. A cobbler can easily remove the old outsole by cutting the outseam and stitch a new one onto the existing welt, dramatically extending the shoe's life.

- Durability: The two-level stitching and robust materials create an incredibly sturdy and long-lasting shoe.

- Water Resistance: By not stitching the outsole directly through to the insole, it creates a more effective barrier against water seeping in from the ground.

- Comfort (Over Time): The cork footbed gradually molds to the specific shape of your foot, creating a custom-like fit after the break-in period.

The Disadvantages

- Higher Cost: The complex process and skilled labor required make Goodyear welted footwear significantly more expensive upfront.

- Stiffness & Break-in: These shoes are notoriously stiff out of the box. The thick insole and cork filling require a break-in period before they become truly comfortable.

- Heavier Weight: The additional materials (welt, cork, often a midsole) result in a heavier and less flexible shoe compared to cemented or Blake-stitched constructions.

Making the Right Choice for Your Goal

Deciding on Goodyear welted footwear depends entirely on your priorities.

- If your primary focus is longevity and value over time: The ability to resole the shoe multiple times makes it a wise long-term investment.

- If your primary focus is immediate comfort and flexibility: You may prefer a different construction, as the break-in period can be demanding.

- If your primary focus is durability for demanding work or weather: The robust and water-resistant nature of a Goodyear welt is a significant practical advantage.

- If your primary focus is budget: The initial cost is a major factor, and more affordable construction methods may be a better starting point.

Ultimately, choosing a Goodyear welt is an investment in a time-tested method that prioritizes durability and repairability above all else.

Summary Table:

| Aspect | Description |

|---|---|

| Inventor | Charles Goodyear Jr. (1870s) |

| Core Principle | A leather welt is stitched to the upper/insole, and the outsole is stitched to the welt. |

| Primary Advantage | Exceptional durability and easy resoling, extending the shoe's lifespan. |

| Key Components | Upper, Insole, Welt, Cork Filling, Outsole. |

| Best For | Long-term value, demanding conditions, and investment in quality. |

Ready to Invest in Superior Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted and other premium footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, ensuring your customers receive the highest quality.

Partner with us to offer footwear built to last.

Contact our team today to discuss your manufacturing needs and how we can bring value to your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What safety boots are recommended for the manufacturing industry? Ensure Complete Protection & Comfort

- What are the advantages of leather as an upper material for work boots? Unmatched Durability & Custom Comfort

- What are the benefits of heavy duty work boots? Invest in Superior Safety & Durability

- Why is slip resistance important in oilfield work boots? Essential Safety & Material Guide

- What advice do physiotherapists give for trying on work boots? Ensure a Perfect Fit for All-Day Comfort

- What are some key features to look for in pull-on work boots? Prioritize Safety, Fit & Durability

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Why is it recommended to try on work boots before buying them? Ensure Perfect Fit & Safety