At its core, the difference between a Western work boot and a traditional work boot comes down to their design heritage and intended environment. Western work boots are built for the demands of ranching and outdoor field work, featuring taller shafts and specific heel shapes, while traditional work boots are engineered for industrial settings with a focus on heavy-duty traction and impact protection.

The choice is not about style, but about function. A Western boot's DNA comes from horseback riding, while a traditional work boot's design is rooted in the factory and construction site. Understanding this origin is the key to selecting the right tool for your job.

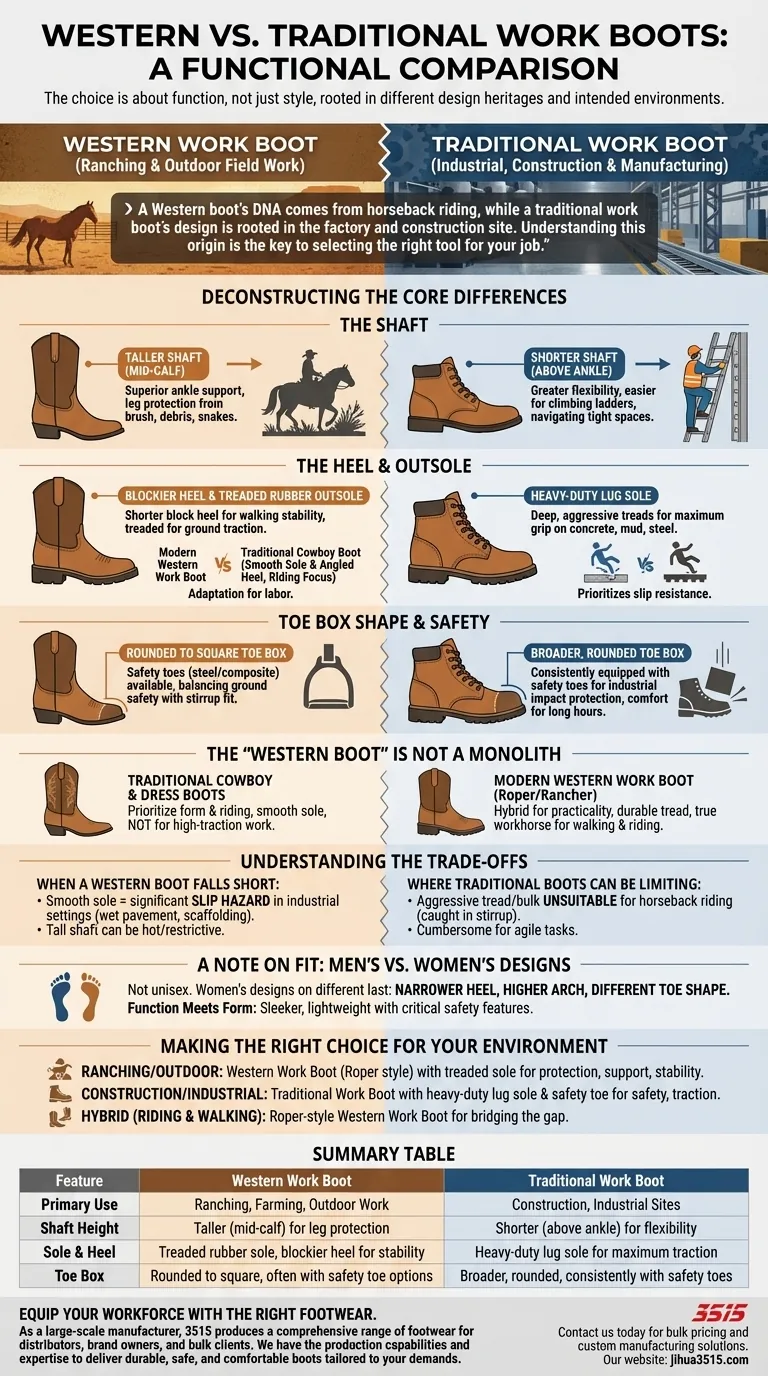

Deconstructing the Core Differences

The functional distinctions between these two types of boots are most apparent in three key areas: the shaft, the sole, and the toe. Each is optimized for a completely different set of tasks.

The Role of the Shaft

A defining feature of the Western boot is its taller shaft, typically rising to the mid-calf. This design provides superior ankle support and protects the leg from brush, debris, or snake bites during outdoor work.

Traditional work boots usually have a shorter shaft, ending just above the ankle. This allows for greater flexibility and is more practical for climbing ladders or navigating tight industrial spaces.

The Heel and Outsole

This is the most critical functional difference. Traditional cowboy boots, designed for riding, feature a smooth leather sole and a taller, angled heel to easily slide into and out of a stirrup.

A true Western work boot, however, adapts this design for labor. It uses a shorter, blockier heel for walking stability and a treaded rubber outsole for better traction on the ground.

In contrast, traditional work boots are defined by their heavy-duty lug soles. These deep, aggressive treads are engineered to grip on surfaces like concrete, mud, and steel grating, prioritizing slip resistance above all else.

Toe Box Shape and Safety

Traditional work boots often have a broader, more rounded toe box to provide comfort during long hours of standing. They are also more consistently equipped with steel or composite safety toes for industrial impact protection.

Western work boots also come with safety toes, but their shape can vary from rounded to square. The design must balance on-the-ground safety with the historical need to fit into a stirrup.

The "Western Boot" Is Not a Monolith

It's crucial to understand that not all boots with a Western aesthetic are designed for work. The category includes everything from ornate dress boots to highly functional, modern work boots.

Traditional Cowboy & Dress Boots

These boots prioritize form and riding function. They often feature intricate stitching, high-quality leathers, and the classic smooth sole and angled heel combination. They are not suitable for high-traction work environments.

The Modern Western Work Boot

This is a hybrid category designed for practicality. Styles like the Roper or Rancher feature shorter shafts and lower, wider heels than a classic cowboy boot. Their primary feature is a durable, treaded rubber sole, making them a true workhorse for both walking and riding.

Understanding the Trade-offs

Neither boot is universally superior; each comes with clear limitations when used outside its intended environment. Choosing the wrong one can impact both safety and comfort.

When a Western Boot Falls Short

The smoother sole of a more traditional Western boot can be a significant slip hazard in industrial settings, on wet pavement, or on scaffolding. The taller shaft, while protective, can also be hot and restrictive for some jobs.

Where Traditional Boots Can Be Limiting

The aggressive tread and heavy build of a traditional work boot make it unsuitable for horseback riding, as it can get caught in a stirrup. The boot's bulk can also feel cumbersome for tasks that require more agility and ground-feel.

A Note on Fit: Men's vs. Women's Designs

Beyond the general style, it's important to recognize that work boots are not unisex. Boots designed specifically for women are built on a different last, or foot model, to ensure proper fit and support.

Beyond Sizing Differences

Women's work boots are engineered to accommodate a typically narrower heel, a higher arch, and a different toe shape. A proper fit is critical for preventing blisters, arch pain, and ensuring safety features function correctly.

Function Meets Form

While both men's and women's boots offer critical safety features like steel toes and slip-resistant soles, women's models often integrate these into a sleeker and more lightweight design.

Making the Right Choice for Your Environment

To select the correct boot, ignore aesthetics and focus entirely on the demands of your daily work.

- If your primary focus is ranching, farming, or outdoor field work: A Western work boot (like a Roper style) with a treaded sole offers the ideal mix of protection, support, and on-ground stability.

- If your primary focus is construction, manufacturing, or industrial sites: A traditional work boot with a heavy-duty lug sole and certified safety toe is the non-negotiable choice for safety and traction.

- If you require a hybrid for both horseback riding and extensive walking: A Roper-style Western work boot is specifically designed to bridge this gap effectively.

Ultimately, choosing the right work boot is about equipping yourself with a specialized tool designed for the unique challenges of your environment.

Summary Table:

| Feature | Western Work Boot | Traditional Work Boot |

|---|---|---|

| Primary Use | Ranching, Farming, Outdoor Work | Construction, Industrial Sites |

| Shaft Height | Taller (mid-calf) for leg protection | Shorter (above ankle) for flexibility |

| Sole & Heel | Treaded rubber sole, blockier heel for stability | Heavy-duty lug sole for maximum traction |

| Toe Box | Rounded to square, often with safety toe options | Broader, rounded, consistently with safety toes |

Equip Your Workforce with the Right Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your team needs the ankle support and ground stability of a Western work boot for outdoor labor or the industrial-grade traction and impact protection of a traditional work boot, we have the production capabilities and expertise to deliver.

Our boots are engineered for durability, safety, and comfort, tailored to the specific demands of your work environment. Let us help you outfit your workforce with the right tool for the job.

Contact us today for bulk pricing and custom manufacturing solutions.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What types of protective toe caps are available in light work boots? Choose the Right Toe Cap for Your Job

- What is the proper way to clean work boots? Extend Boot Life with Gentle Cleaning

- Where can heavy duty work boots be purchased? Find the Right Supplier for Your Needs

- Which type of boot offers better fit retention over time? The Answer Lies in Adjustable Design

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What are firefighter boots and what are they designed for? Essential Protection for First Responders

- What is the primary purpose of lace-to-toe boots? Achieve a Perfect, Customizable Fit

- What are some specialized features found in work boots? Key Features for Safety & Performance