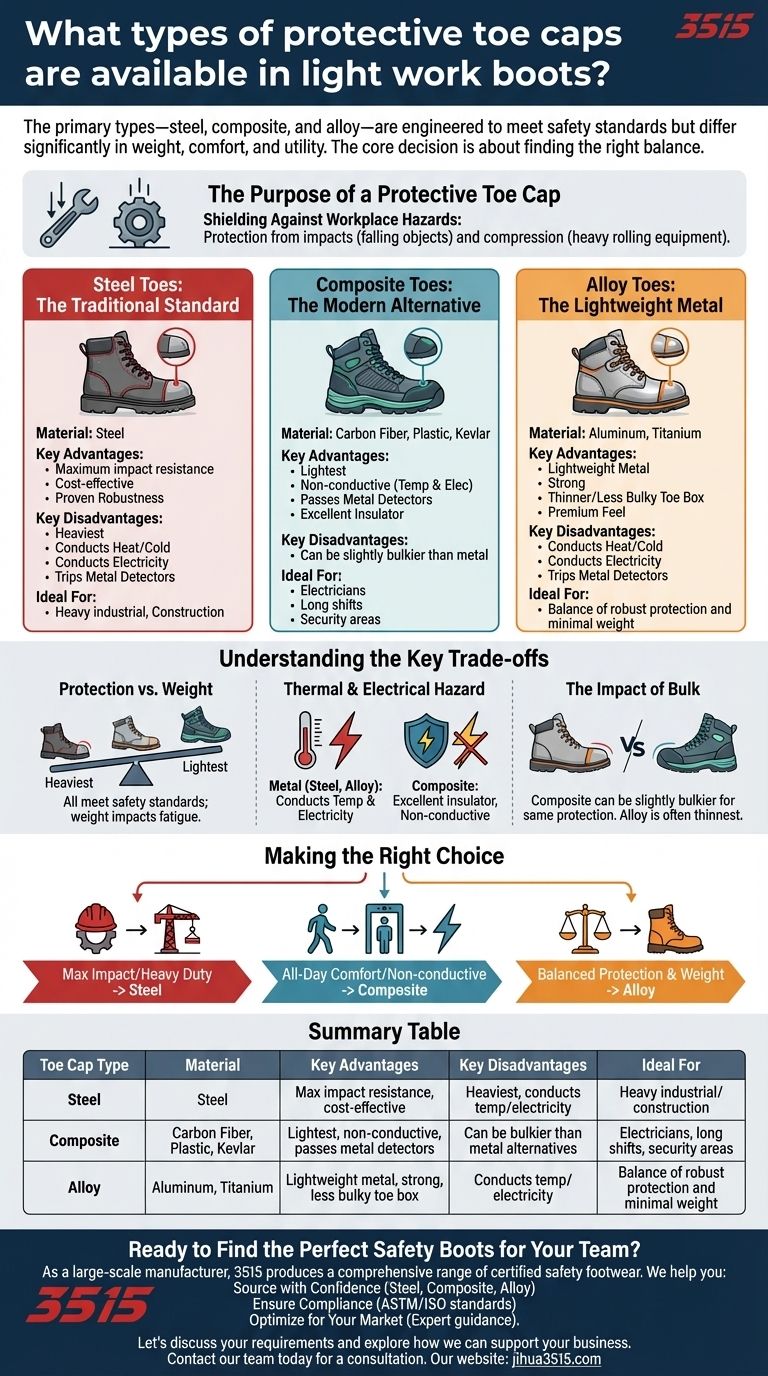

In light work boots, the primary types of protective toe caps you will encounter are steel, composite, and alloy. Each is engineered to meet specific safety standards for impact and compression, but they achieve this with different materials, resulting in significant differences in weight, comfort, and utility.

The core decision is not about finding the "strongest" toe cap, but about selecting the material that provides the right balance of protection, weight, and environmental suitability for your specific workday.

The Purpose of a Protective Toe Cap

Shielding Against Workplace Hazards

A protective toe cap is a reinforcement built into the front of a work boot. Its sole function is to protect your toes from common job site injuries.

These hazards include impacts from falling objects, such as tools or building materials, and compression from heavy rolling equipment or machinery.

A Breakdown of the Core Materials

Steel Toes: The Traditional Standard

Steel is the original material for safety toes and remains the benchmark for robust protection. It offers excellent resistance to impact, compression, and puncture from sharp objects.

While highly effective, steel is also the heaviest option and readily conducts heat and cold, which can be a comfort issue in extreme temperatures.

Composite Toes: The Modern Alternative

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. Their primary advantage is being significantly lighter than steel.

This makes them ideal for roles requiring long hours of walking or standing. As they contain no metal, they do not conduct electricity or temperature and will not set off metal detectors, a key benefit for electricians or workers in high-security environments.

Alloy Toes: The Lightweight Metal

Alloy toes, typically made from materials like aluminum or titanium, offer a middle ground. They provide the strength and protection of metal but are considerably lighter than steel.

They can be made thinner than steel caps, often resulting in a less bulky, more comfortable toe box in the boot. However, like steel, they will conduct temperature and be detected by metal scanners.

Understanding the Key Trade-offs

Protection vs. Weight

All three types must meet the same ASTM safety standards for impact and compression. The primary user-facing difference is weight.

Steel is the heaviest, alloy is lighter, and composite is the lightest of all. Over a full day, this weight difference can have a significant impact on fatigue and overall comfort.

Thermal Conductivity and Electrical Hazard

Metal (steel and alloy) is a natural conductor. In cold weather, the toe cap will feel cold, and in hot weather, it can retain heat. Composite materials, by contrast, are excellent insulators against temperature.

For electricians or those working near live circuits, non-metallic composite toes are the only safe option as they do not conduct electricity.

The Impact of Bulk

Because of material strength differences, composite toe caps sometimes need to be slightly bulkier than their metal counterparts to provide the same level of protection.

This can occasionally make the boot's toe box feel more constrictive, though modern designs have largely mitigated this issue. Alloy toes are often the thinnest and least obtrusive.

Making the Right Choice for Your Work

Choosing the right toe cap means matching the material's properties to your daily tasks and environment.

- If your primary focus is maximum impact resistance in a heavy industrial or construction setting: Steel remains the proven, cost-effective standard for rugged protection.

- If your primary focus is all-day comfort, mobility, or you work around metal detectors: Composite offers lightweight, non-conductive protection ideal for long shifts.

- If your primary focus is a balance of robust protection and minimal weight: Alloy provides a premium, lightweight metal option that feels less bulky than the alternatives.

Ultimately, the best work boot is the one that keeps you safe without causing unnecessary fatigue.

Summary Table:

| Toe Cap Type | Material | Key Advantages | Key Disadvantages | Ideal For |

|---|---|---|---|---|

| Steel | Steel | Maximum impact resistance, cost-effective | Heaviest, conducts temperature/electricity | Heavy industrial/construction |

| Composite | Carbon Fiber, Plastic, Kevlar | Lightest, non-conductive, passes metal detectors | Can be bulkier than metal alternatives | Electricians, long shifts, security areas |

| Alloy | Aluminum, Titanium | Lightweight metal, strong, less bulky toe box | Conducts temperature/electricity | Balance of robust protection and minimal weight |

Ready to Find the Perfect Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, ensuring you get the right combination of protection, comfort, and durability.

We help you:

- Source with Confidence: Access a wide catalog of boots featuring steel, composite, and alloy toe caps.

- Ensure Compliance: All our safety footwear meets or exceeds relevant ASTM/ISO standards.

- Optimize for Your Market: Get expert guidance on the best products for your specific customer needs.

Let's discuss your requirements and explore how we can support your business.

Contact our team today for a consultation

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do you apply boot wax for waterproofing? Achieve a Durable, Moisture-Repellent Seal

- What should be monitored to maintain cowboy boots against wear and tear? A Proactive Inspection Guide

- How many layers of wax are recommended for optimal waterproofing? The Secret to a Durable Seal

- How do employer replacement rules impact the use of work boots? A Guide to Proactive Safety

- What are the key considerations when choosing work boot materials? Find the Perfect Boot for Your Job

- What does the 'C' in ASTM F2413-18 M/I/C EH PR MT stand for? Essential Guide to Compression Resistance

- How do EH-rated work boots protect against electrical hazards? Insulate Against Shock with Certified Safety

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort