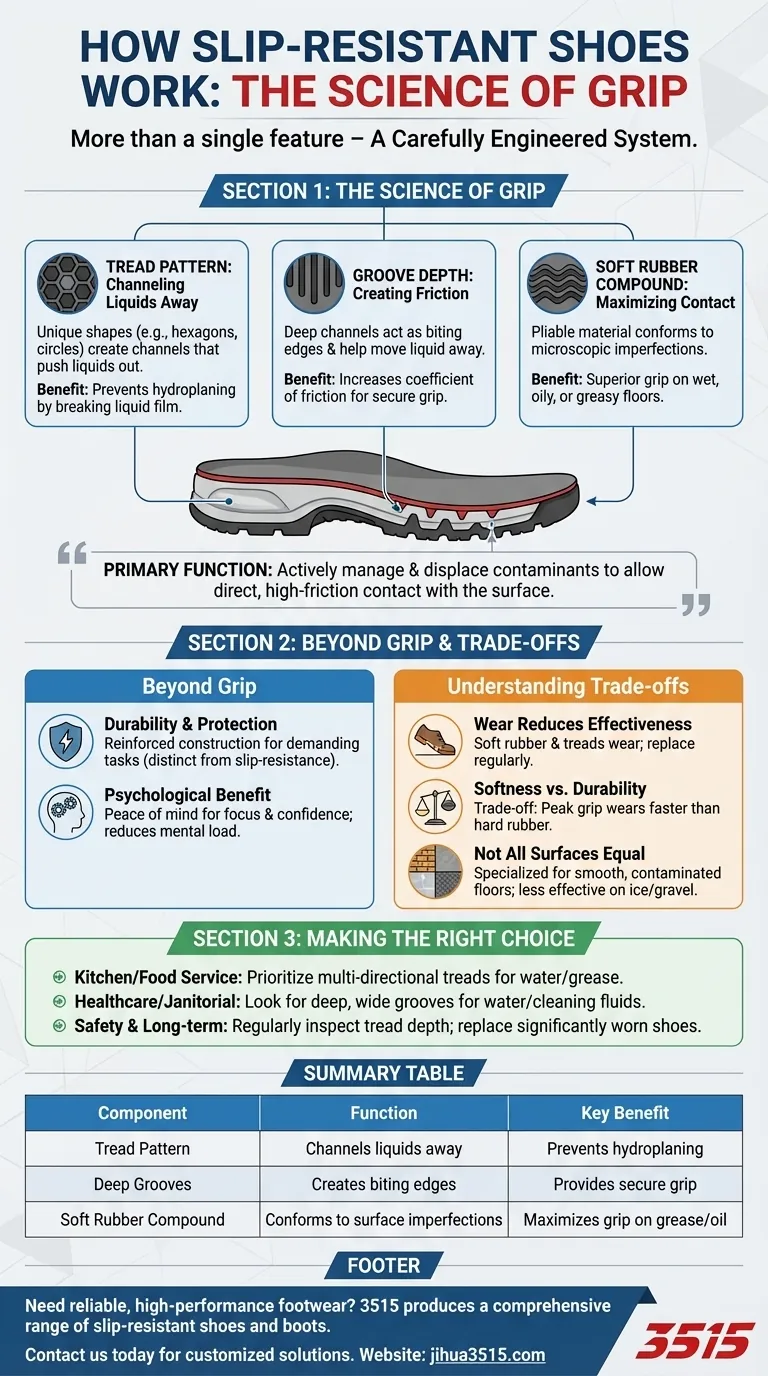

The effectiveness of slip-resistant shoes lies not in a single feature, but in a carefully engineered system. These shoes prevent falls by focusing entirely on the design of the outsole—the part that contacts the floor. They use specific tread patterns to channel liquids away, deep grooves to create friction, and specialized soft rubber compounds to maximize grip on slick surfaces like wet or oily floors.

A slip-resistant shoe is not designed to simply stick to the floor. Its primary function is to actively manage and displace contaminants like water and oil, allowing the specialized rubber to make direct, high-friction contact with the actual surface below.

The Science of Grip: Deconstructing the Outsole

The entire slip-resistance mechanism is built into the shoe's outsole. Understanding how these three core components work together is key to appreciating their effectiveness.

Tread Pattern: Channeling Liquids Away

The shapes you see on the bottom of the shoe, often small circles or hexagons, are not for aesthetics. They are designed to create channels that push liquids out from under the sole.

This function prevents a dangerous phenomenon similar to a car hydroplaning, where a layer of liquid separates the sole from the floor, eliminating friction almost entirely.

Groove Depth: Creating More Friction

Between the tread patterns are deep grooves. These grooves work with the tread to efficiently move liquids away from the shoe's point of contact with the floor.

More importantly, these deep channels create more biting edges, which increase the coefficient of friction and provide a more secure grip on the walking surface.

Material Composition: The Role of Soft Rubber

Slip-resistant shoes are made from softer rubber compounds than typical footwear. This soft material is crucial for gripping surfaces contaminated with oil or grease.

The pliable rubber can better conform to microscopic imperfections in a floor's surface, maximizing the contact area and creating a stronger hold.

Beyond Grip: What Defines a Quality Work Shoe?

While the outsole provides the slip resistance, other elements contribute to a shoe's overall safety and performance in a professional environment.

Durability and Protection

Many slip-resistant shoes, especially work boots, are built with reinforced materials and sturdy construction to withstand demanding tasks.

Features like reinforced toes protect against impact, but it's important to remember that these durability features are distinct from the outsole technology that prevents slips.

The Psychological Benefit

Knowing your footing is secure provides significant peace of mind. This allows workers in fast-paced or hazardous environments, like kitchens or hospitals, to focus on their tasks with confidence and stability.

This reduction in mental load is a critical, though often overlooked, safety benefit that helps prevent accidents.

Understanding the Trade-offs

No safety equipment is perfect. Acknowledging the limitations of slip-resistant shoes is essential for using them effectively.

Wear and Tear Reduces Effectiveness

The features that make these shoes work—soft rubber and deep treads—are also susceptible to wear. As the outsole wears down and the treads become shallow, the shoe's ability to channel liquid and grip the floor diminishes significantly.

They should be viewed as a consumable piece of safety equipment that requires regular inspection and replacement.

The Softness vs. Durability Balance

The soft rubber compounds that provide excellent grip on slick surfaces can wear out more quickly than the harder rubber used in standard shoes. This is a fundamental trade-off between peak performance and longevity.

Not All Surfaces Are Equal

A shoe designed for a greasy kitchen floor may not be the best choice for icy conditions or loose gravel. The technology is highly specialized for preventing slips on smooth surfaces contaminated with liquids.

Making the Right Choice for Your Goal

Your specific workplace environment dictates the most critical features to look for in a slip-resistant shoe.

- If your primary focus is working in a kitchen or food service: Prioritize shoes with intricate, multi-directional tread patterns designed to repel both water and grease.

- If your primary focus is healthcare or janitorial work: Look for deep, wide grooves that can effectively channel away significant amounts of water and cleaning fluids from smooth flooring.

- If your primary focus is safety and long-term value: Regularly inspect the tread depth of your outsoles and plan to replace them as soon as you see significant wear.

Ultimately, the right slip-resistant shoe transforms a hazardous floor into a predictable and safe surface.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Tread Pattern | Channels liquids (water, oil) away from the sole | Prevents hydroplaning on wet surfaces |

| Deep Grooves | Creates more biting edges for increased friction | Provides a secure grip on the walking surface |

| Soft Rubber Compound | Conforms to microscopic floor imperfections | Maximizes contact area for superior grip on grease/oil |

Need reliable, high-performance footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of occupational footwear, engineered with the precise outsole technology detailed above to ensure safety and durability.

We can help you equip your workforce with the right footwear to prevent slips and boost confidence. Contact us today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What technologies are used in modern slip resistant shoes? Advanced Grip & Safety Explained

- How can ice grips improve shoe traction on icy surfaces? Prevent slips with mechanical grip.

- In what conditions are non-slip shoes particularly beneficial? Essential for Wet & Slippery Environments

- How do slip-resistant shoes benefit older individuals? Prevent Falls and Enhance Stability

- What are the key benefits of wearing slip resistant shoes? Boost Safety & Productivity

- What are the best shoes to wear if you're on your feet all day? A Guide to Lasting Comfort & Support

- What are some effective methods to make shoes non-slip? Achieve Secure Footing with Proven Techniques

- What are the benefits of slip-resistant shoes for women in the workplace? Prevent Costly Falls & Boost Productivity