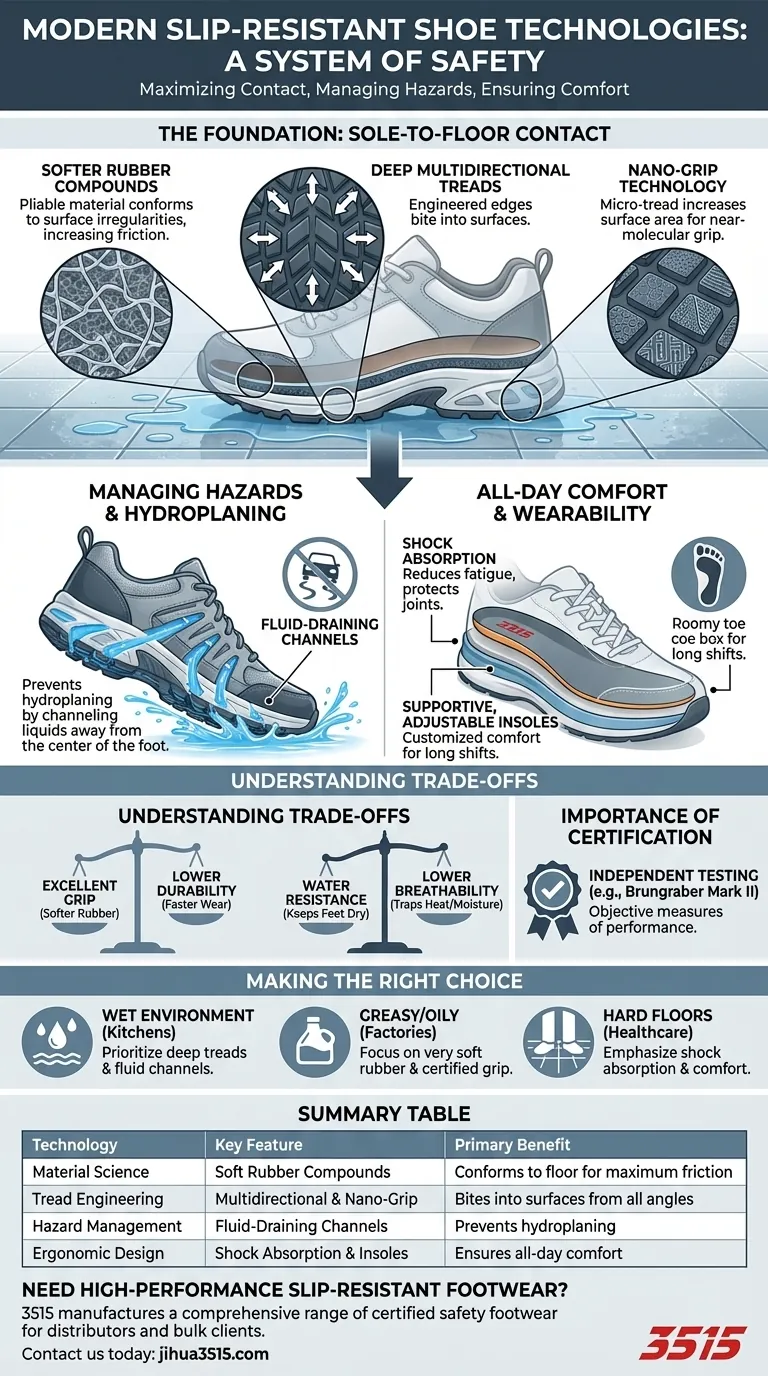

The core technologies in modern slip-resistant shoes focus on maximizing the sole's contact with the ground, actively channeling away liquids, and ensuring all-day comfort for the wearer. Innovations include specialized rubber compounds, microscopic tread patterns known as Nano-Grip, and sole designs engineered to prevent hydroplaning by draining fluids.

True slip resistance is not achieved by a single feature, but through a system of technologies working together. The most effective shoes combine an advanced outsole tread design with materials and features that manage environmental hazards while providing the comfort necessary for consistent, all-day use.

The Foundation: Maximizing Sole-to-Floor Contact

The primary goal of any slip-resistant shoe is to maintain as much friction as possible between the sole and the walking surface, even when contaminants like water or oil are present.

The Critical Role of Material

The outsole is typically made from a softer rubber compound. Unlike the harder rubber on a hiking boot, this softer material is more pliable and can conform better to microscopic irregularities on a floor surface, significantly increasing the contact area and grip.

The Science of Tread Design

Effective slip-resistant shoes feature deep, multidirectional grooves or tread patterns. These patterns are not random; they are engineered to create multiple sharp edges that can bite into the walking surface for better traction from any angle.

Pushing the Limits with Micro-Tread

Some of the most advanced shoes incorporate Nano-Grip technology. This involves creating microscopic patterns within the larger tread blocks, further increasing the sole's surface area to establish a secure grip at a near-molecular level.

Beyond Grip: Managing Workplace Hazards

A great tread is only part of the solution. The shoe must also be able to handle the specific environmental challenges that cause slips in the first place.

Preventing Hydroplaning

The most common cause of slipping is a thin layer of liquid that lifts the shoe off the floor, similar to a car hydroplaning on a wet road. Fluid-draining soles feature carefully designed channels that actively push liquids out and away from the center of the foot, ensuring the rubber tread stays in direct contact with the floor.

Ensuring All-Day Safety and Wearability

A shoe is only effective if it's worn. Modern designs incorporate ergonomic features to reduce fatigue and encourage consistent use. These include shock absorption materials in the midsole to protect joints and supportive, often adjustable insoles to provide customized comfort. A roomy toe box is also common to accommodate natural foot swelling over a long shift.

Understanding the Trade-offs

No single shoe is perfect for every situation. Understanding the inherent compromises in design is key to selecting the right tool for the job.

Grip vs. Durability

The softer rubber compounds that provide excellent grip also tend to wear down faster than harder materials. This means the most effective slip-resistant shoes may need to be replaced more frequently to maintain peak performance, a critical factor when considering long-term value.

Water Resistance vs. Breathability

While water resistance is crucial for keeping feet dry and safe from hot liquids or chemicals, it can also trap heat and moisture. This can lead to discomfort, making breathability an important consideration for workers in hot environments who are not exposed to significant splash hazards.

The Importance of Certification

Marketing claims can be misleading. Independent testing provides an objective measure of performance. Look for shoes that meet industry standards, such as those validated by the Brungraber Mark II Test or similar slip-resistance certifications, to ensure you are getting proven technology.

Making the Right Choice for Your Environment

Your specific workplace hazards should guide your final decision.

- If your primary focus is a wet environment (e.g., kitchens, dish rooms): Prioritize shoes with deep, open tread patterns and dedicated fluid-draining channels to prevent hydroplaning.

- If your primary focus is a greasy or oily environment (e.g., industrial factories, auto shops): Look for certified shoes made from a very soft rubber compound that can maintain grip on viscous fluids.

- If your primary focus is all-day comfort on hard floors (e.g., healthcare, event staff): Emphasize features like superior shock absorption, supportive insoles, and a lightweight, accommodating fit.

Ultimately, the best slip-resistant shoe is one that intelligently combines material science, tread engineering, and ergonomic design to solve the specific safety challenges you face every day.

Summary Table:

| Technology | Key Feature | Primary Benefit |

|---|---|---|

| Material Science | Soft Rubber Compounds | Conforms to floor for maximum friction |

| Tread Engineering | Multidirectional & Nano-Grip Patterns | Bites into surfaces from all angles |

| Hazard Management | Fluid-Draining Channels | Prevents hydroplaning on wet floors |

| Ergonomic Design | Shock Absorption & Supportive Insoles | Ensures all-day comfort and wearability |

Need high-performance, certified slip-resistant footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the latest technologies to protect your workforce and meet industry standards.

Contact us today to discuss your specific needs and discover how we can provide durable, comfortable, and certified safety solutions for your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- How is puncture resistance evaluated in footwear soles? Balance Protection, Comfort & Safety

- Why is slip resistance important in safety footwear? Prevent Costly Workplace Slips and Falls

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection