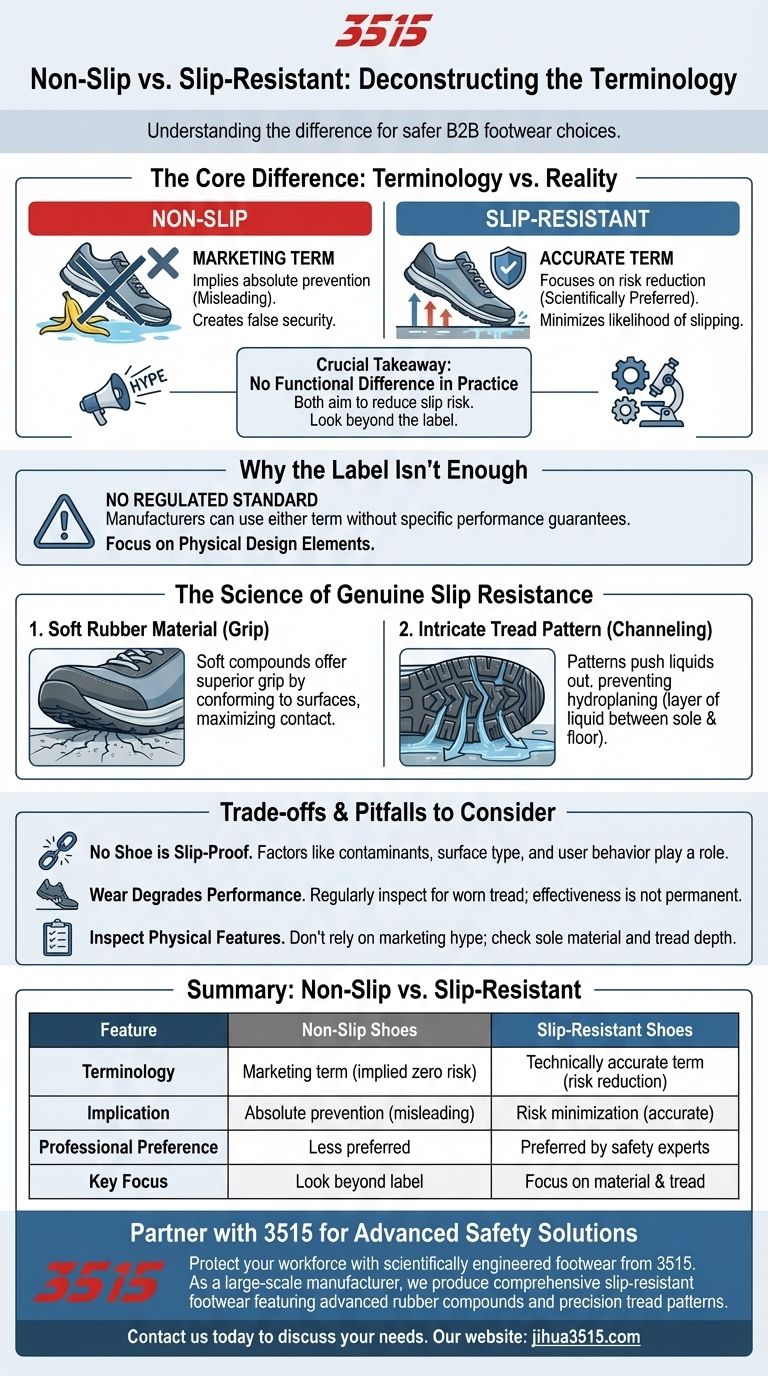

In simple terms, there is no functional difference. The terms "non-slip" and "slip-resistant" are used interchangeably to describe shoes designed to reduce the risk of falling on slick surfaces. However, "slip-resistant" is the more accurate and professionally preferred term, as "non-slip" implies an impossible guarantee of preventing all slips.

The critical takeaway is not the word on the box, but the features of the shoe itself. Since neither term is officially regulated, you must look past the marketing language and focus on the sole's material and tread design to ensure genuine protection.

Deconstructing the Terminology

While often used as synonyms, the two terms carry different implications. Understanding this nuance is the first step toward making a more informed and safer choice.

The Problem with "Non-Slip"

"Non-slip" is primarily a marketing term. It suggests an absolute state—that the shoe will not, under any circumstances, slip.

This is a dangerous and misleading claim. No footwear can completely eliminate the risk of slipping in all conditions. This term can create a false sense of security.

The Accuracy of "Slip-Resistant"

"Slip-resistant" is the technically correct term preferred by safety experts and scientific organizations. It accurately describes the shoe's function.

This footwear is engineered to reduce the likelihood of slipping by increasing the coefficient of friction between the sole and the walking surface. The focus is on risk minimization, not elimination.

Why the Label Doesn't Tell the Whole Story

Relying on a label alone is a mistake. The effectiveness of a shoe comes from its physical design, not the word used to describe it.

The Lack of a Regulated Standard

Crucially, there is no government-regulated definition for either term. A manufacturer can label a shoe "non-slip" or "slip-resistant" without meeting a specific, universal performance standard.

This is why you must become an informed buyer and inspect the shoe's features directly.

What Actually Creates Resistance

True slip resistance comes from two key design elements working together: the sole material and the tread pattern.

The Role of the Sole Material

Softer rubber compounds offer superior grip. These materials are more pliable and can conform better to microscopic imperfections in a floor surface, maximizing contact and friction, especially on wet or greasy floors.

The Science of Tread Patterns

Look for intricate, open-ended tread patterns. The design is not for aesthetics; it's for function. Good patterns create channels that push liquids like water and oil out from under the shoe's sole.

This channeling action prevents a layer of liquid from forming between the sole and the floor, a phenomenon known as hydroplaning, which is a primary cause of slips.

Understanding the Trade-offs and Pitfalls

Even the best slip-resistant shoes have limitations. Recognizing them is essential for staying safe.

No Shoe is Slip-Proof

Factors beyond the shoe's design can cause a fall. These include the type and amount of contaminant on the floor, the floor's surface material, and how the wearer is walking or carrying items.

Wear and Tear Degrades Performance

The effectiveness of a slip-resistant shoe is not permanent. As the soft rubber sole and its tread pattern wear down from use, the shoe loses its ability to grip and channel fluids effectively.

You must regularly inspect your shoes. If the tread is visibly worn and smooth, it's time to replace them.

Making the Right Choice for Your Goal

Ignore the marketing hype and focus on the physical evidence to meet your specific needs.

- If your primary focus is workplace safety: Look for shoes that are explicitly rated for your environment (e.g., "oil-resistant") and prioritize models that are verifiably tested, regardless of the label.

- If your primary focus is everyday stability: Inspect the shoe's sole for a soft, pliable rubber and a deep, complex tread pattern with channels that run to the edge.

- If your primary focus is evaluating current shoes: Check the tread depth. If the pattern is worn smooth in key contact areas, the shoe no longer offers meaningful slip resistance.

Ultimately, your safety depends on understanding the shoe's function, not just trusting its name.

Summary Table:

| Feature | Non-Slip Shoes | Slip-Resistant Shoes |

|---|---|---|

| Terminology | Marketing term implying zero slip risk | Technically accurate term for risk reduction |

| Implication | Absolute prevention (misleading) | Risk minimization (accurate) |

| Professional Preference | Less preferred | Preferred by safety experts |

| Key Focus | Look beyond label to sole design | Focus on material softness and tread pattern |

Protect your workforce with scientifically engineered footwear from 3515. As a large-scale manufacturer, we produce comprehensive slip-resistant footwear for distributors, brand owners, and bulk clients. Our shoes feature advanced rubber compounds and precision tread patterns that meet the highest safety standards.

Contact us today to discuss your specific needs and discover how our production capabilities can deliver the perfect safety solution for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What materials are typically used in non-slip shoe outsoles? The Science of Slip-Resistant Footwear

- What are the benefits of using high-grip anti-slip work shoes for MBR tank maintenance? Ensure worker safety today!

- What are safety clogs designed for? The Ultimate Guide to Hygienic & Slip-Resistant Footwear

- Why is investing in quality anti-slip shoes important? A Smart Move for Safety & Savings

- What is the most effective long-term solution for making shoes non-slip? Achieve Permanent Safety with Professional Resoling

- What materials are best for non-slip shoes? Achieve Superior Traction and Safety

- What is the difference between anti-slip and non-slip terminology? Uncover the Truth for Real Safety

- What are the three key design features that make slip-resistant shoes effective? Master Workplace Safety